8 Diagnostic Testing and Troubleshooting

256 July 29, 2013, 715003794 Rev. B

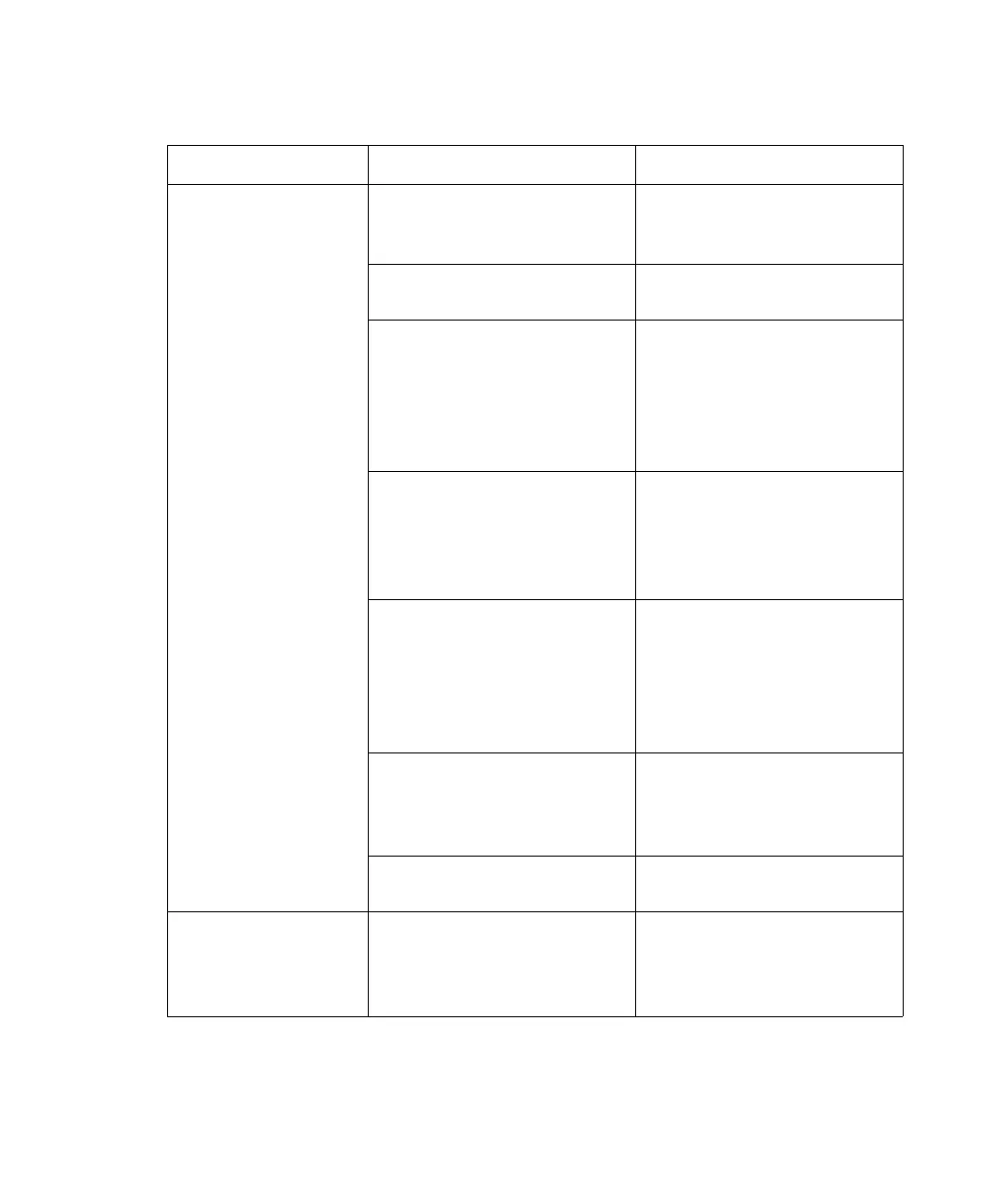

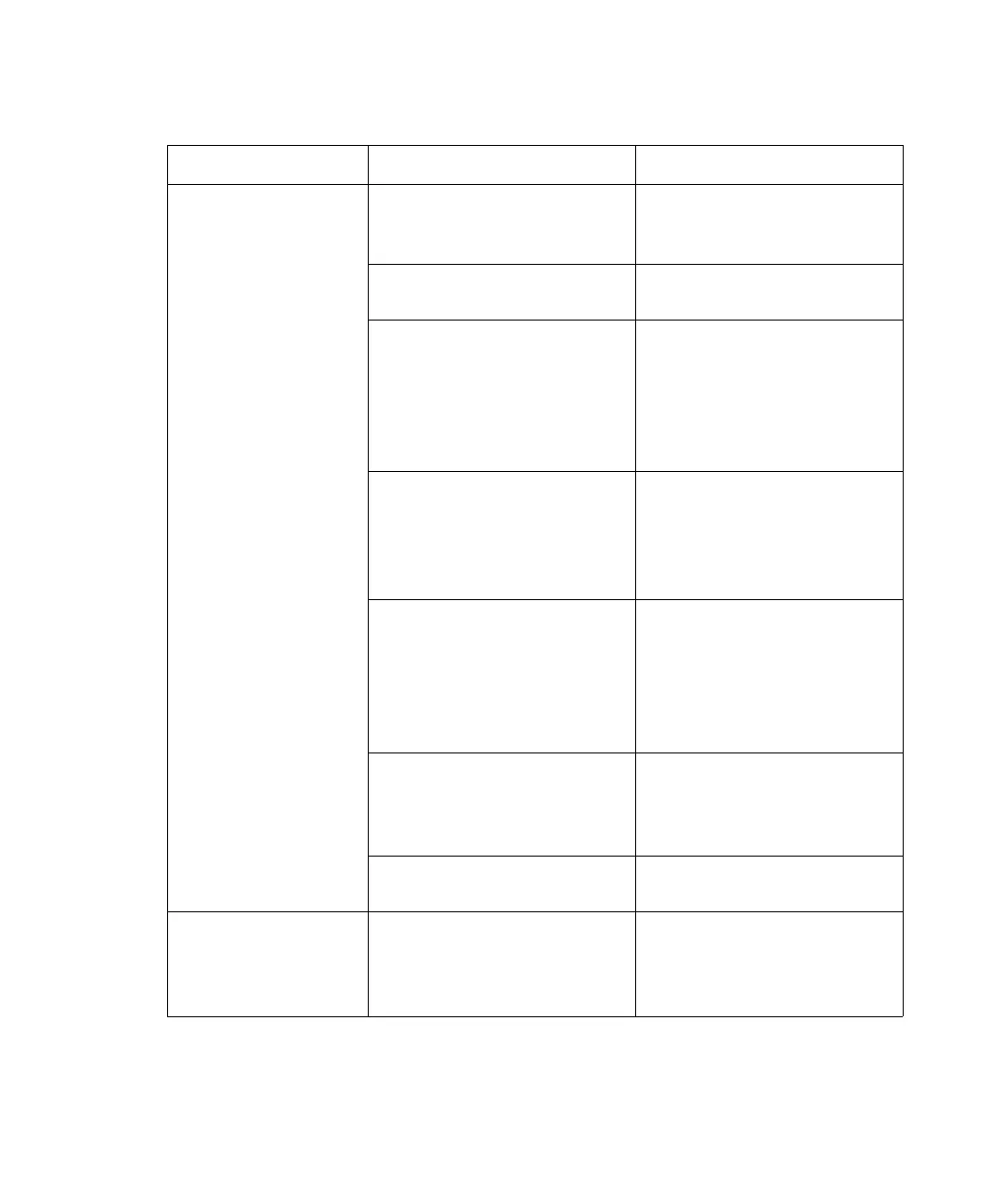

Sample management system troubleshooting:

Symptom Possible cause Corrective action

Compression check

failed

Syringe contains an air

bubble (usually seen at top

or bottom of syringe)

Remove air bubble (see

“Replace the syringe” on

page 205).

Mobile phase not properly

degassed

Degas mobile phase.

Incorrect syringe used for

test or syringe data

incorrectly entered in the

Configuration screen

Install a syringe of the

correct size, consulting the

syringe data in the

Configuration screen (see

“Replace the syringe” on

page 205).

Leaks at tubing

connections

Inspect for leakage at the

connections with a tissue,

and tighten connection

slightly if the tissue is

moistened.

Seal pack failure Adjust the seals (see

“Adjust the seals” on

page 226). Replace the

seal pack (see “Replace the

injector needle and seal

pack” on page 209).

Parameters used for

compression check

unacceptable for solvent

Set the appropriate

parameters, then repeat

the compression check in

the Diagnostics screen.

Valve V3 (waste valve)

faulty

Call Waters Technical

Service.

Leak at seal pack Damaged needle, seal

pack

Replace needle and seal

pack (see “Replace the

injector needle and seal

pack” on page 209).

Loading...

Loading...