February 2013

4-415

ColorQube® 9303 Family

ADJ 62.1

Repairs/Adjustments

ADJ 62.1 Optics Cleaning Procedure

Parts List on PL 62.15

Purpose

To clean the optical components of the scanner ensuring optimum image quality.

NOTE: This adjustment must only be performed if directed to it from an Image Quality RAP, or

if the optics cavity was opened to install a new component and contamination can be seen.

Procedure

WARNING

Ensure that the electricity to the machine is switched off while performing tasks that do

not need electricity. Refer to GP 14. Disconnect the power cord. Electricity can cause

death or injury. Moving parts can cause injury.

CAUTION

Observe ESD precautions during this procedure.

1. Remove the DADH, REP 5.19.

2. Remove the CVT ramp, CVT glass and document glass assembly, REP 62.3.

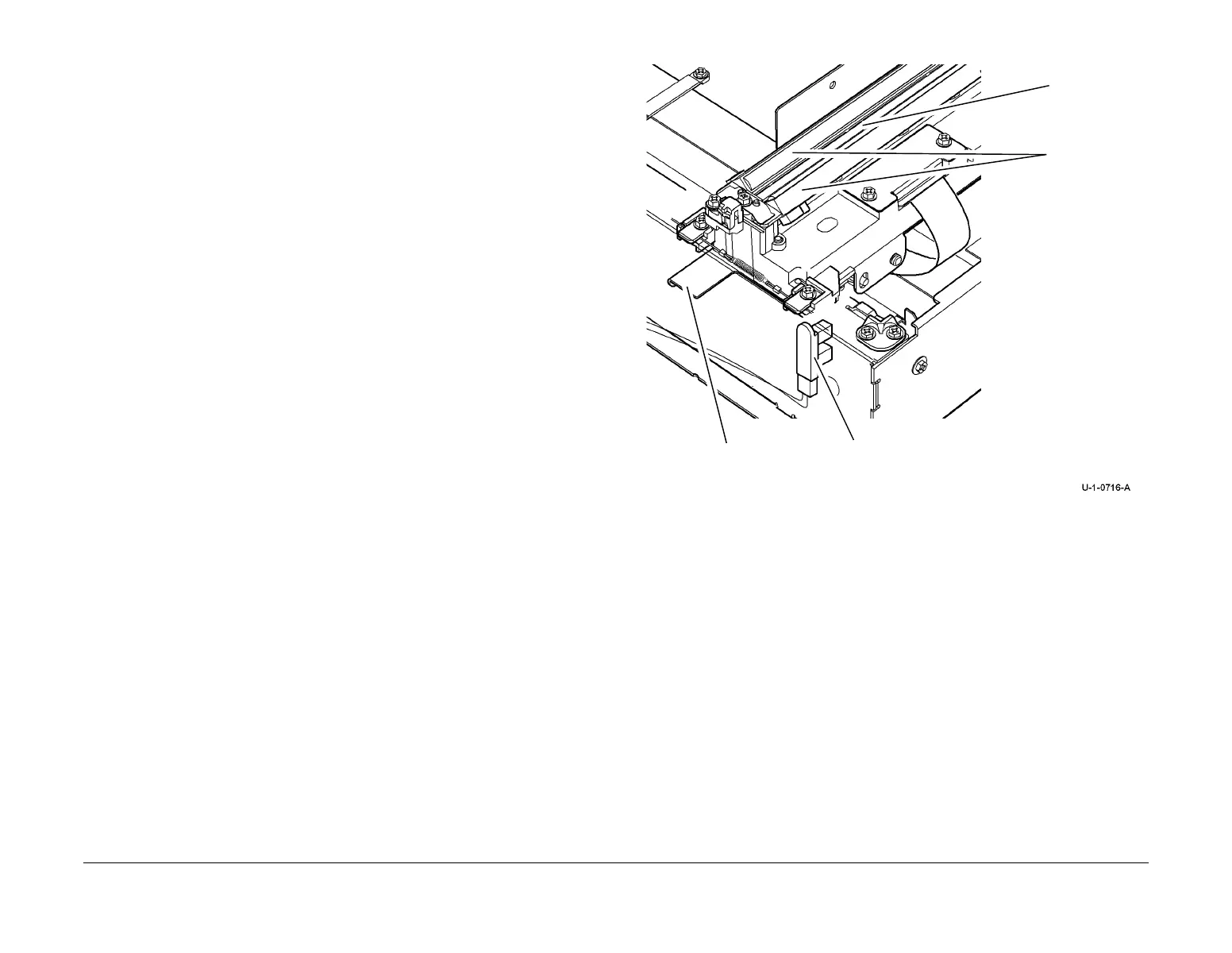

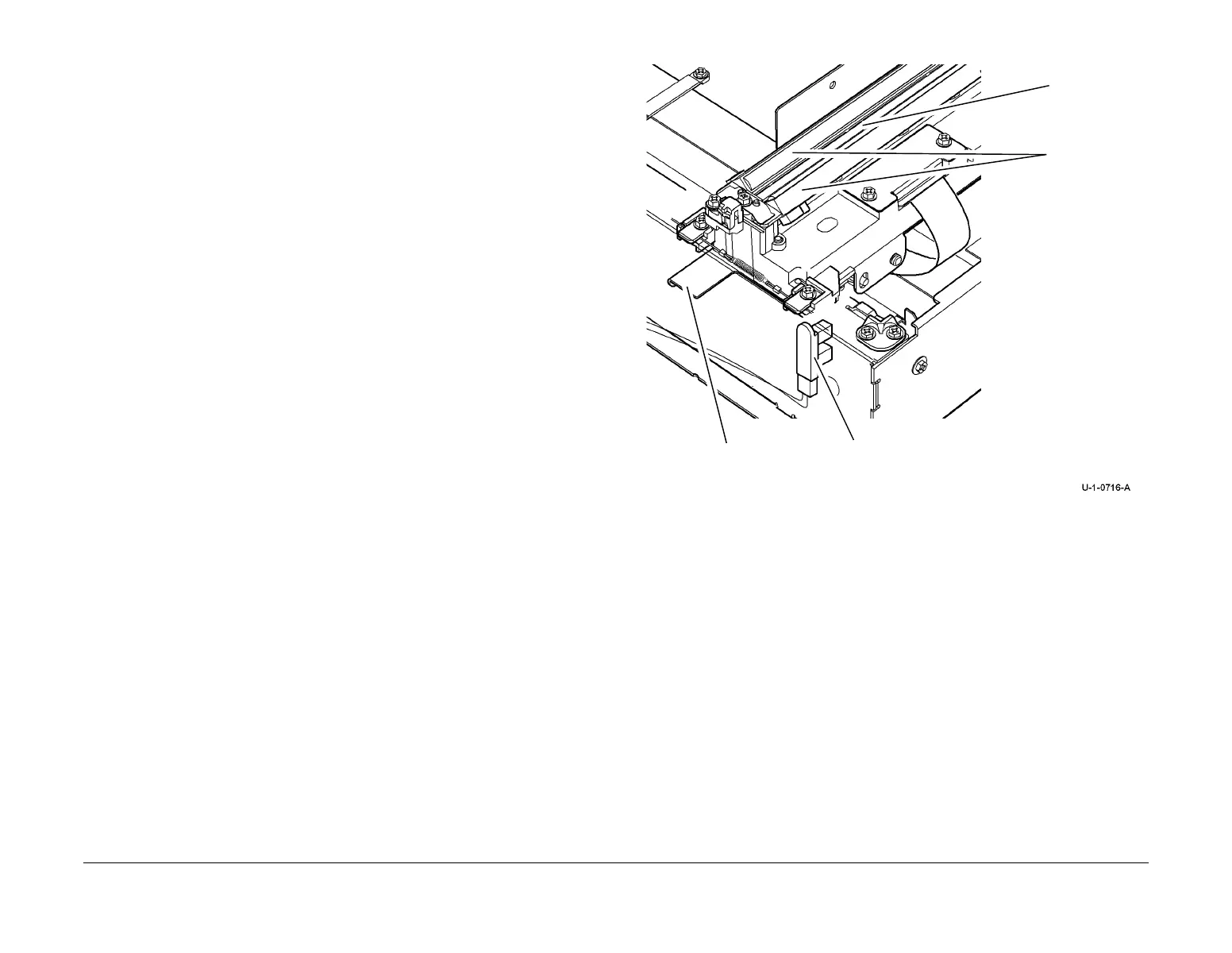

3. Inspect the LED exposure lamps, Figure 1. If necessary, clean them as follows:

a. Vacuum clean the area to remove all visible contamination. Take care not to touch

the LED exposure lamps with the cleaning nozzle. It may be necessary to move the

scan carriage assembly gently to the left. It is advisable to leave it in this position, but

it can be returned to the home position by depressing slightly to allow the flag to

enter the gap in the scan carriage home sensor.

b. Wash your hands.

c. Carefully clean the LED exposure lamps, with a micro fibre cleaning cloth, PL 26.10

Item 6, dampened with antistatic fluid, PL 26.10 Item 11.

d. Polish the LED lamps and top of the scan carriage with a dry micro fibre cleaning

cloth, PL 26.10 Item 6.

4. Clean the lenses of the document size sensors, PL 62.16 Item 10, with a micro fibre

cleaning cloth, PL 26.10 Item 6.

5. Inspect the document glass and CVT glass and if necessary, clean them as follows:

a. Clean the under side of document glass and CVT glass using a micro fibre cleaning

cloth, PL 26.10 Item 6, dampened with antistatic fluid, PL 26.10 Item 11.

b. Polish the under side of document glass and CVT glass with a dry micro fibre clean-

ing cloth, PL 26.10 Item 6.

c. Install the document glass and CVT glass, taking care not to smear the cleaned

underside, REP 62.3.

NOTE: Ensure that the white AGC strip on both the CVT glass and the document

glass, are at the front of the machine and on the underside of the glass.

d. Clean the upper side of document glass and CVT glass using a micro fibre cleaning

cloth, dampened with film remover, PL 26.11 Item 14.

e. Polish the upper side of document glass and CVT glass using a dry, micro fibre

cleaning cloth.

6. Re-install the remainder of the removed components.

Figure 1 Optics cleaning

Scan carriage

Scan carriage

home sensor

Flag

Exposure

lamps

Loading...

Loading...