67C3K11 5-46

1

2

3

4

5

6

7

8

9

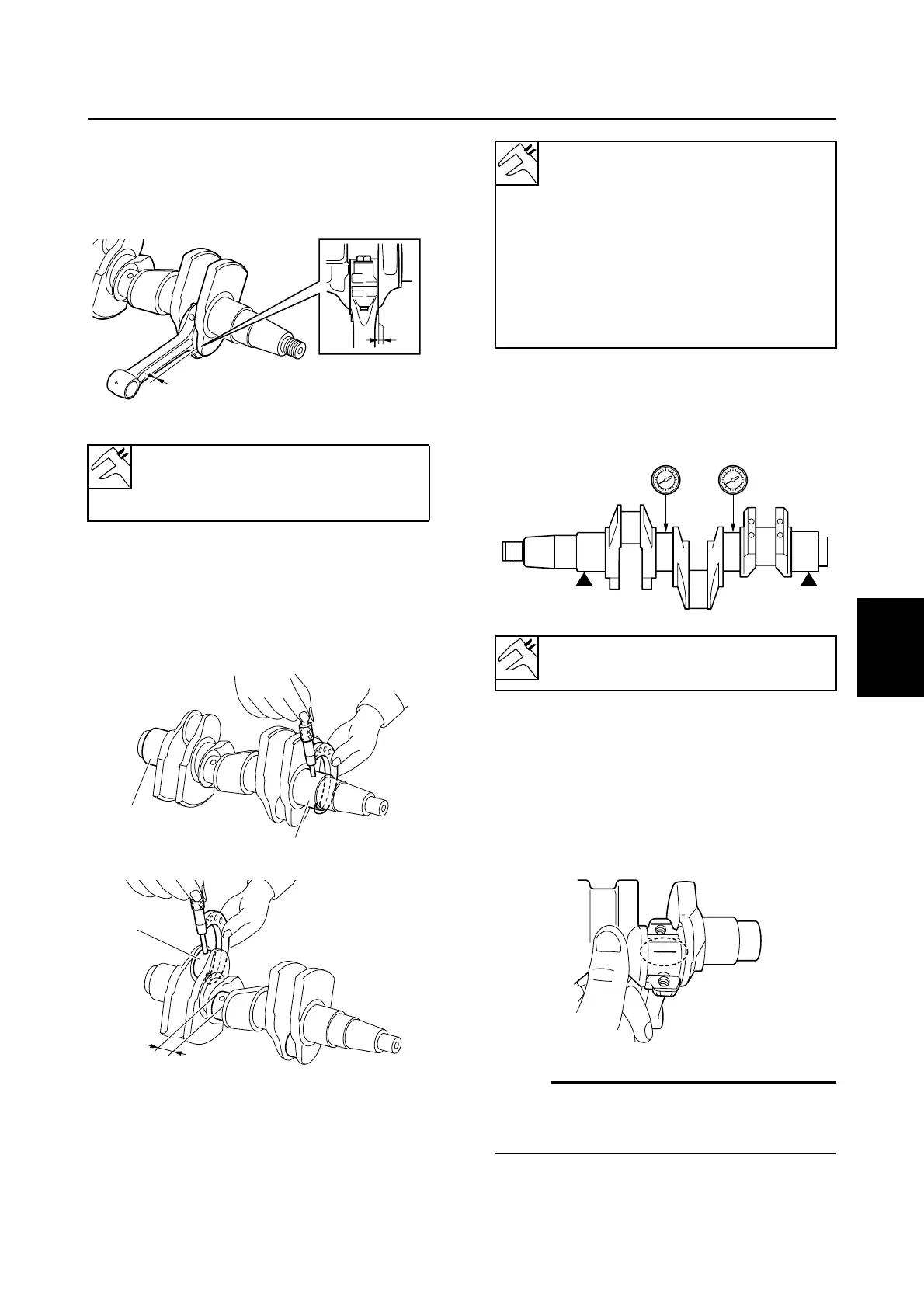

Checking the connecting rod big end

side clearance

1. Measure the connecting rod big end side

clearance a.

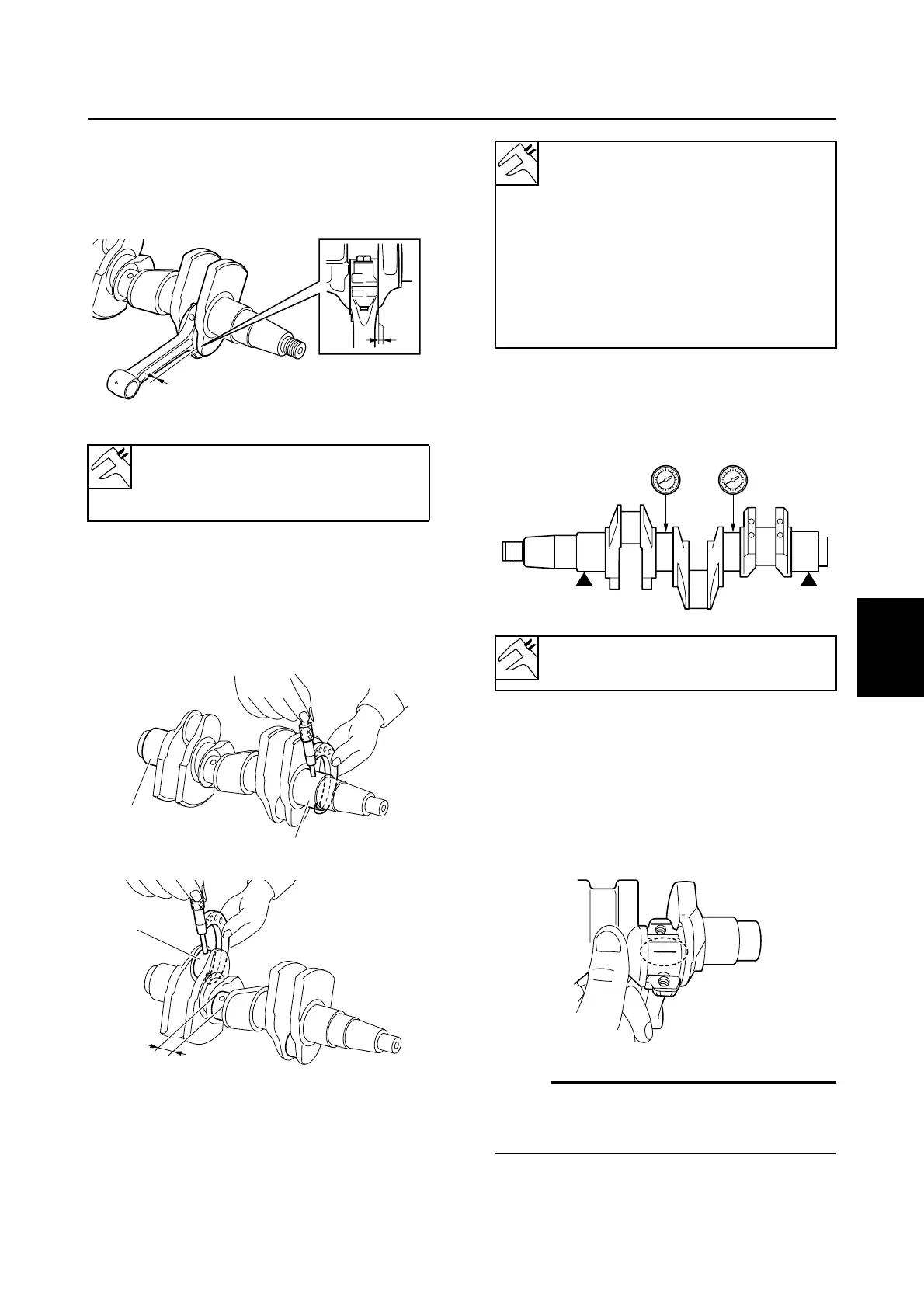

Checking the crankshaft

1. Measure the crankshaft journal diame-

ters a, crankpin diameters b, and

crankpin widths c. Replace the crank-

shaft if out of specification.

2. Measure the crankshaft runout. Replace

if above specification.

Checking the crankpin oil clearance

1. Clean the bearings, connecting rods and,

crankpin.

2. Put a piece of Plastigauge (PG-1) onto

the crankpin, parallel to the crankshaft.

NOTE:

Be sure not to put the Plastigauge (PG-1)

over the oil hole in the crankpin of the crank-

shaft.

Connecting rod big end side

clearance a (reference data):

0.12–0.15 mm (0.0047–0.0059 in)

S67C5135

a

a

S67C5136

a

a

S67C5137

c

b

Crankshaft journal diameter a:

42.984–43.000 mm

(1.6923–1.6929 in)

Crankpin diameter b:

32.984–33.000 mm

(1.2986–1.2992 in)

Crankpin width c:

21.000–21.070 mm

(0.8268–0.8295 in)

Crankshaft runout limit:

0.05 mm (0.0020 in)

S67C5138

S6AU5144

Cylinder block

Loading...

Loading...