POWR

Power unit

5-47 67C3K11

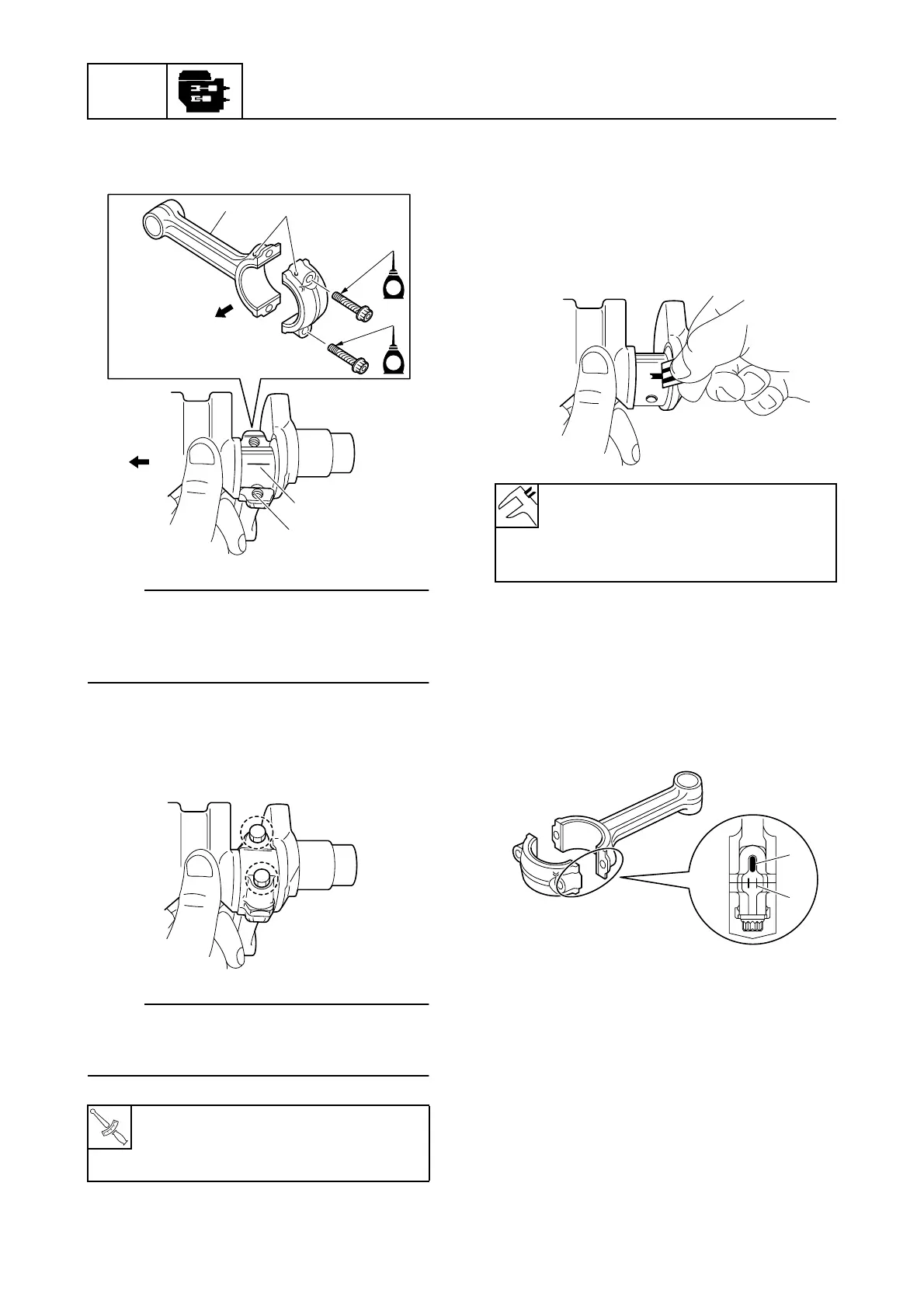

3. Install the connecting rod 1 and bear-

ings to the crankpin 2.

NOTE:

Make sure that the projections a on the con-

necting rod and connecting rod cap face

towards the flywheel magnet end È of the

crankshaft.

4. Tighten the connecting rod cap bolts to

the specified torques in 2 stages.

NOTE:

Do not turn the connecting rod until the

crankpin oil clearance measurement has

been completed.

5. Remove the connecting rod cap and

measure the width of the compressed

Plastigauge (PG-1) on the crankpin.

Check the connecting rods, bearings,

and crankshaft if out of specification and

replace the defective parts.

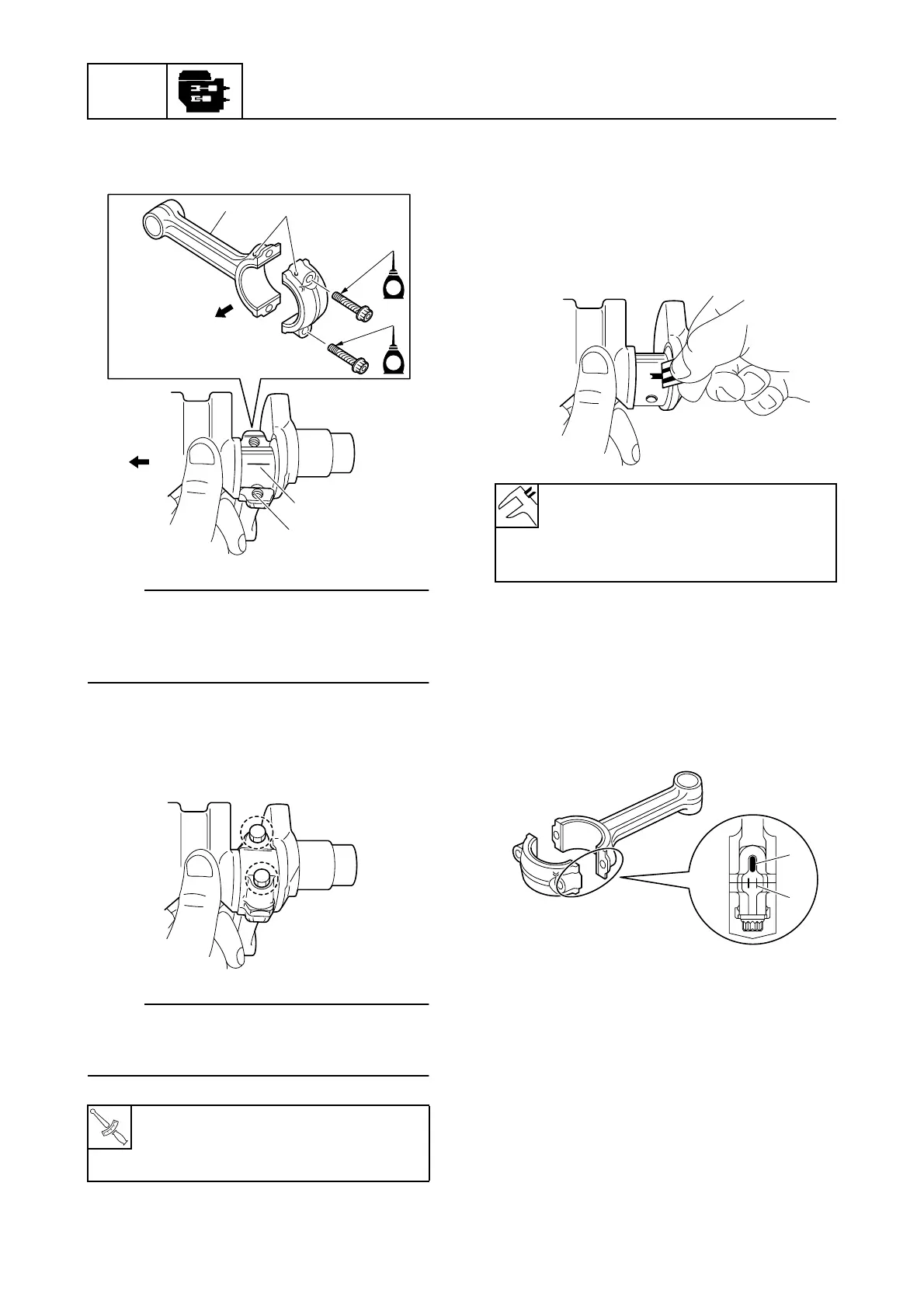

Selecting the connecting rod bearing

1. When replacing the connecting rod bear-

ing, select the suitable bearing as fol-

lows.

2. Check the connecting rod mark a or

painted color b on the connecting rod.

3. Select the suitable bearing color c for

the connecting rod bearing from the

table.

T

R

.

.

Connecting rod cap bolt:

1st: 6 N·m (0.6 kgf·m, 4.4 ft·lb)

2nd: 17 N·m (1.7 kgf·m, 12.5 ft·lb)

S67C5140

2

1

È

1

a

È

E

E

S6AU5146

Crankpin oil clearance (reference

data):

0.020–0.052 mm

(0.0008–0.0020 in)

S6AU5147

S67C5171

b

a

Loading...

Loading...