67C3K11 4-4

1

2

3

4

5

6

7

8

9

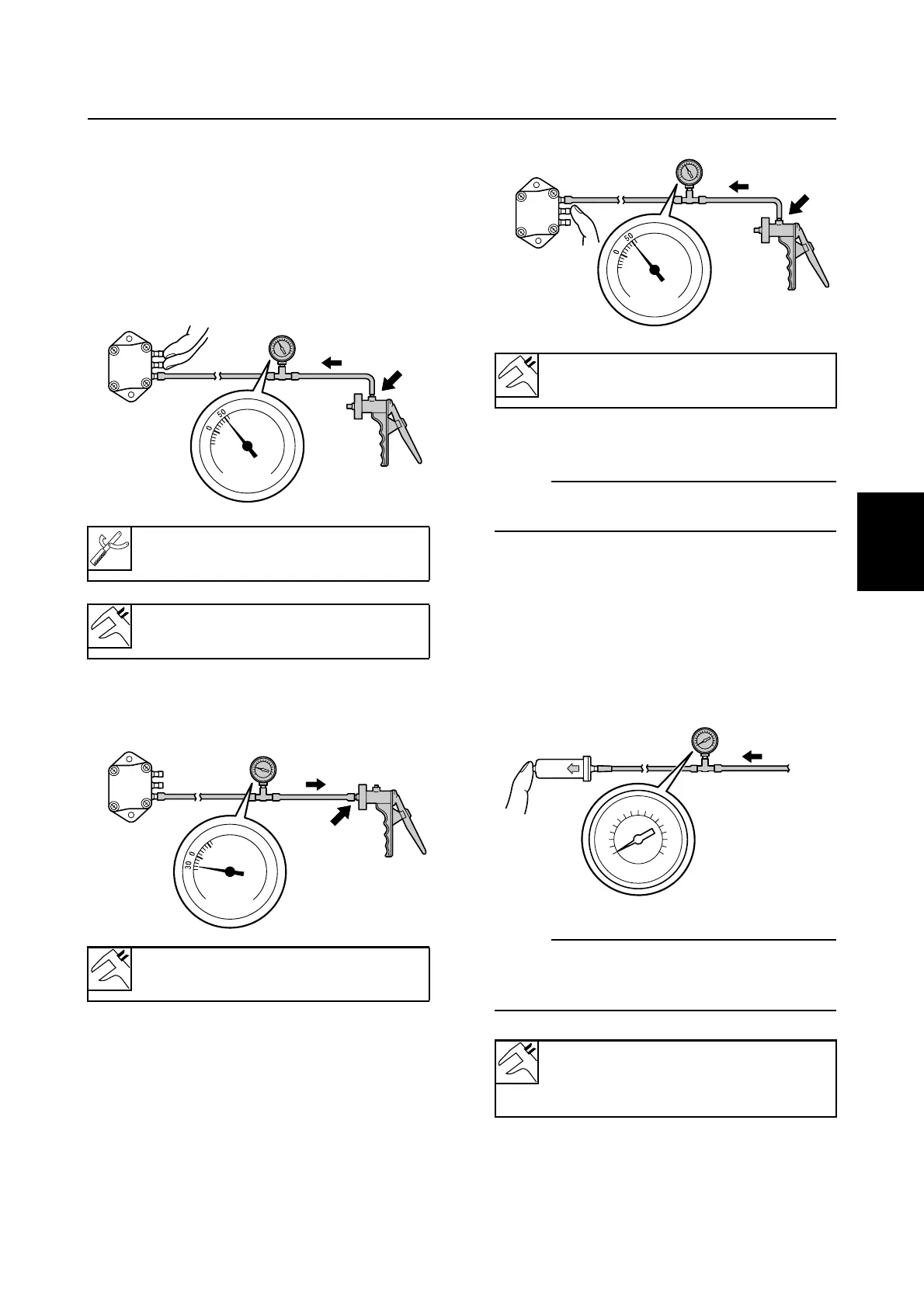

Checking the fuel pump

1. Connect the special service tool to the

fuel pump inlet.

2. Cover the fuel pump outlets with your fin-

gers, and then apply the specified posi-

tive pressure. Check that there is no air

leakage.

3. Apply the specified negative pressure

and check that there is no air leakage.

4. Connect the special service tool to 1 fuel

pump outlet and cover the other fuel

pump outlet with your finger.

5. Apply the specified positive pressure and

check that there is no air leakage.

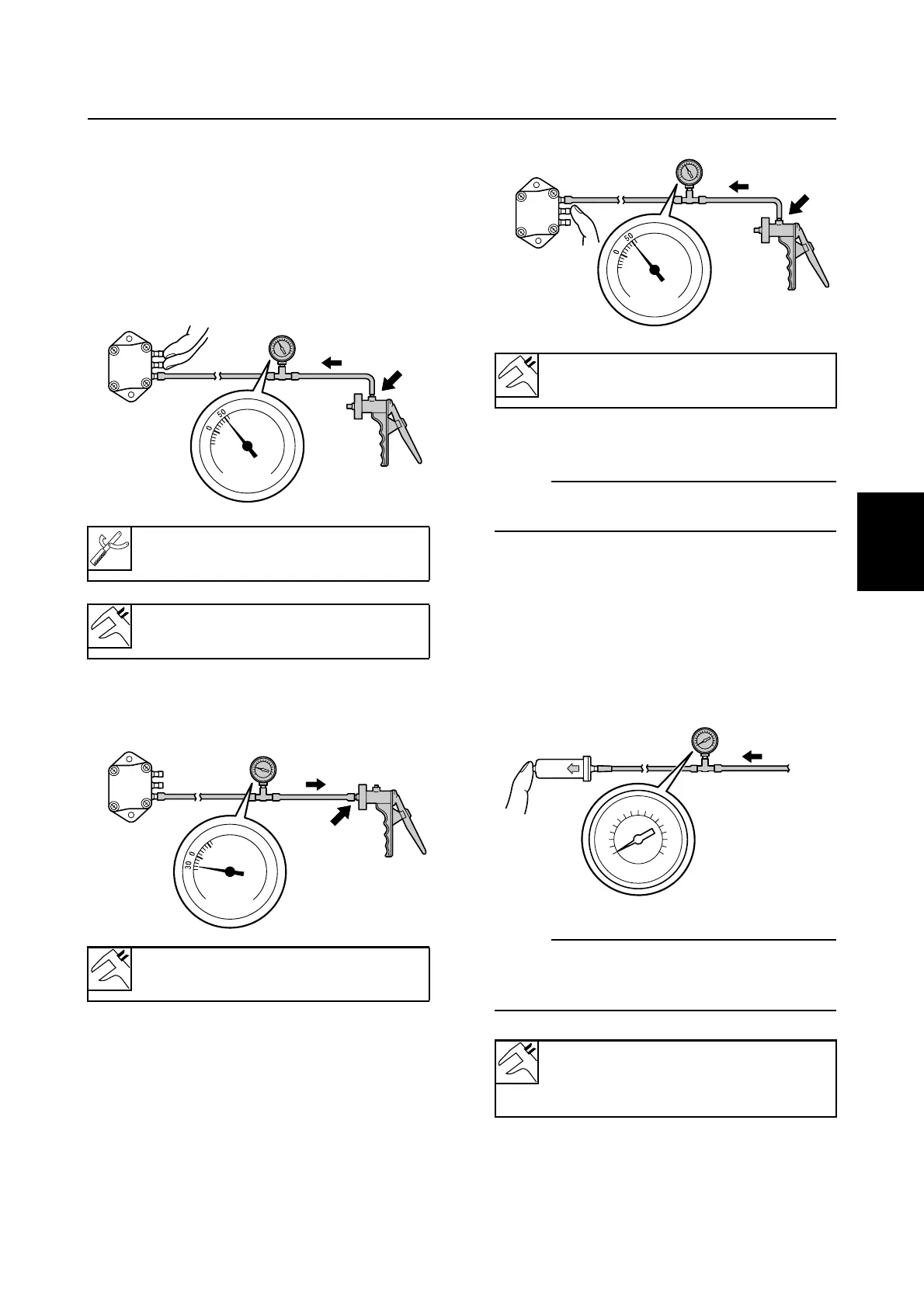

Checking the fuel filter

NOTE:

To check the fuel filter, see “Checking the

fuel filter” (3-3).

1. Connect a meter to the fuel inlet.

2. Cover the fuel outlet with your finger, and

then apply the specified positive pres-

sure. Replace the fuel filter if the speci-

fied pressure cannot be maintained for at

least 10 seconds.

NOTE:

Use a commercially available compressor

and meter that can be pressurized up to

1,035 kPa (10.35 kgf/cm

2

, 150.1 psi).

Vacuum/pressure pump gauge set:

90890-06756

Specified positive pressure:

50 kPa (0.5 kgf/cm

2

, 7.3 psi)

Specified negative pressure:

30 kPa (0.3 kgf/cm

2

, 4.4 psi)

S67C4004

OUT

OUT

I N

S67C4005

OUT

OUT

I N

Specified positive pressure:

50 kPa (0.5 kgf/cm

2

, 7.3 psi)

Specified positive pressure:

1,035 kPa

(10.35 kgf/cm

2

, 150.1 psi)

S67C4006

OUT

OUT

I N

S67C4007

01000

Fuel pump, fuel filter, and fuel joint

Loading...

Loading...