9-3

Chapter 9. PLC Link Communication Function

9 - 2 Data Transmission

PLC link communication is a function for transferring data between the PLC and this controller. There are two

transfer types: “Cyclic data transfer” and “Triggered data transfer.”

The type of transfer can be set in the PLC link settings of the SLP-C1F Smart Loader Package.

The upper limits for the number of transfer processes and number of sheets are shown below.

Function Maximum No. of

sheets

Maximum No. of

processes in 1 sheet

Total maximum No. of

sheets for the function

Total maximum No. of

processes for the

function

Cyclic data transfer 4 sheets 64 lines 4 sheets 64 lines

Triggered data transfer 4 sheets 64 lines

z

Cyclic data transfer

Data from the controller can be transferred to the PLC periodically. Data can also

be transferred from the host device to the controller.

Major applications:

• Saving controller data to the PLC

• Monitoring controller data by the PLC for device management

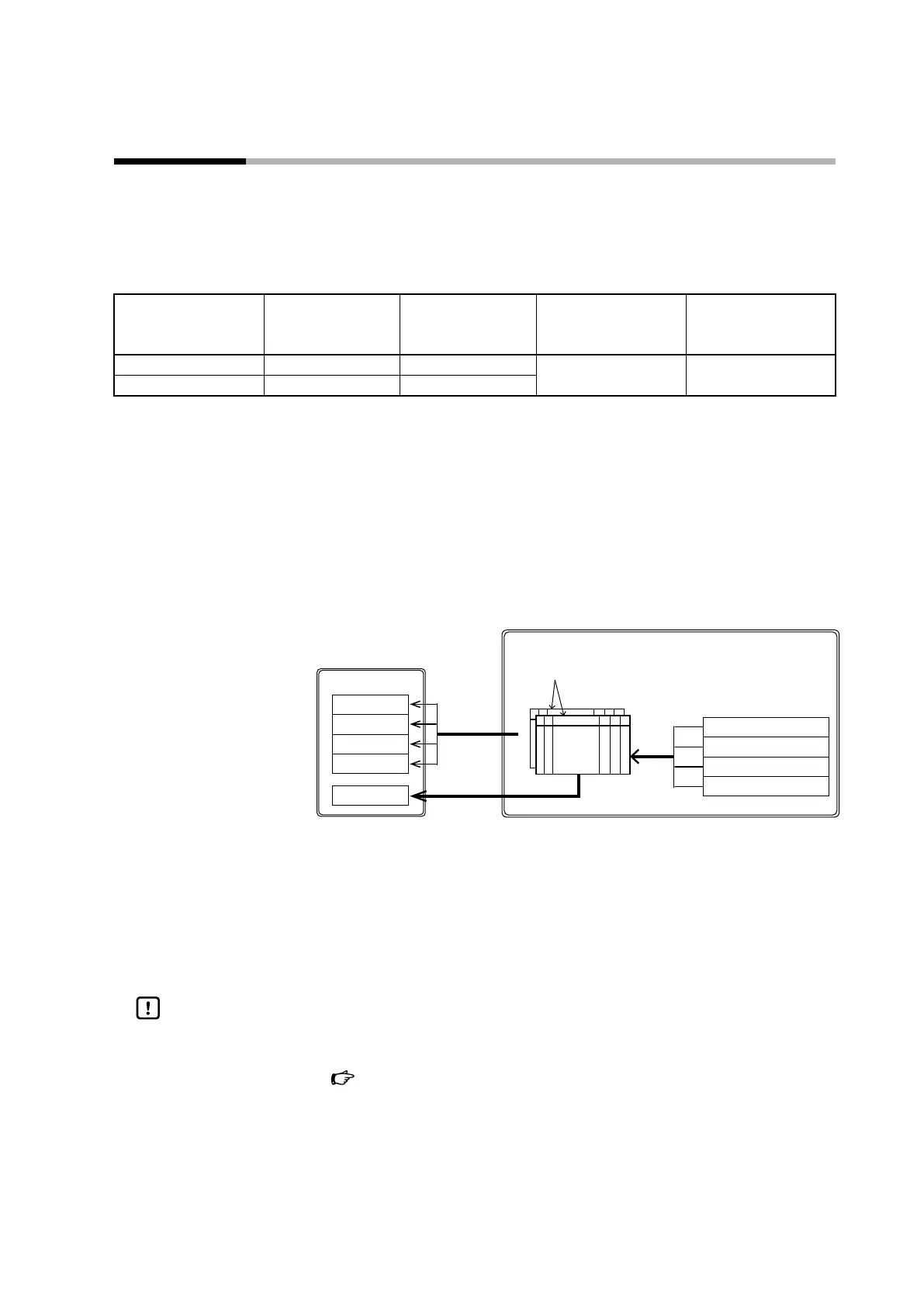

The controller transfers data periodically as follows.

PLC

Model C1M

D0000

D0001

D0002

D0003

M0010

(2) Read

(1) Cyclic start of data transmission

(3) Write

PV

MV

Input alarm status

Instrument alarm status

(1) The controller starts cyclic data transfer according to the configuration sheets.

(2) Data is read from the controller.

(3) The read data is written to the PLC.

(4) When transfer of the data specified for the sheet is complete, a completion

notification is written.

Handling Precautions

• The normal memory area and RAM area are available for the data written from

the PLC to the C1M.

Chapter 10. List of Communication Data (for details)

Loading...

Loading...