SERIAL LINKS 161

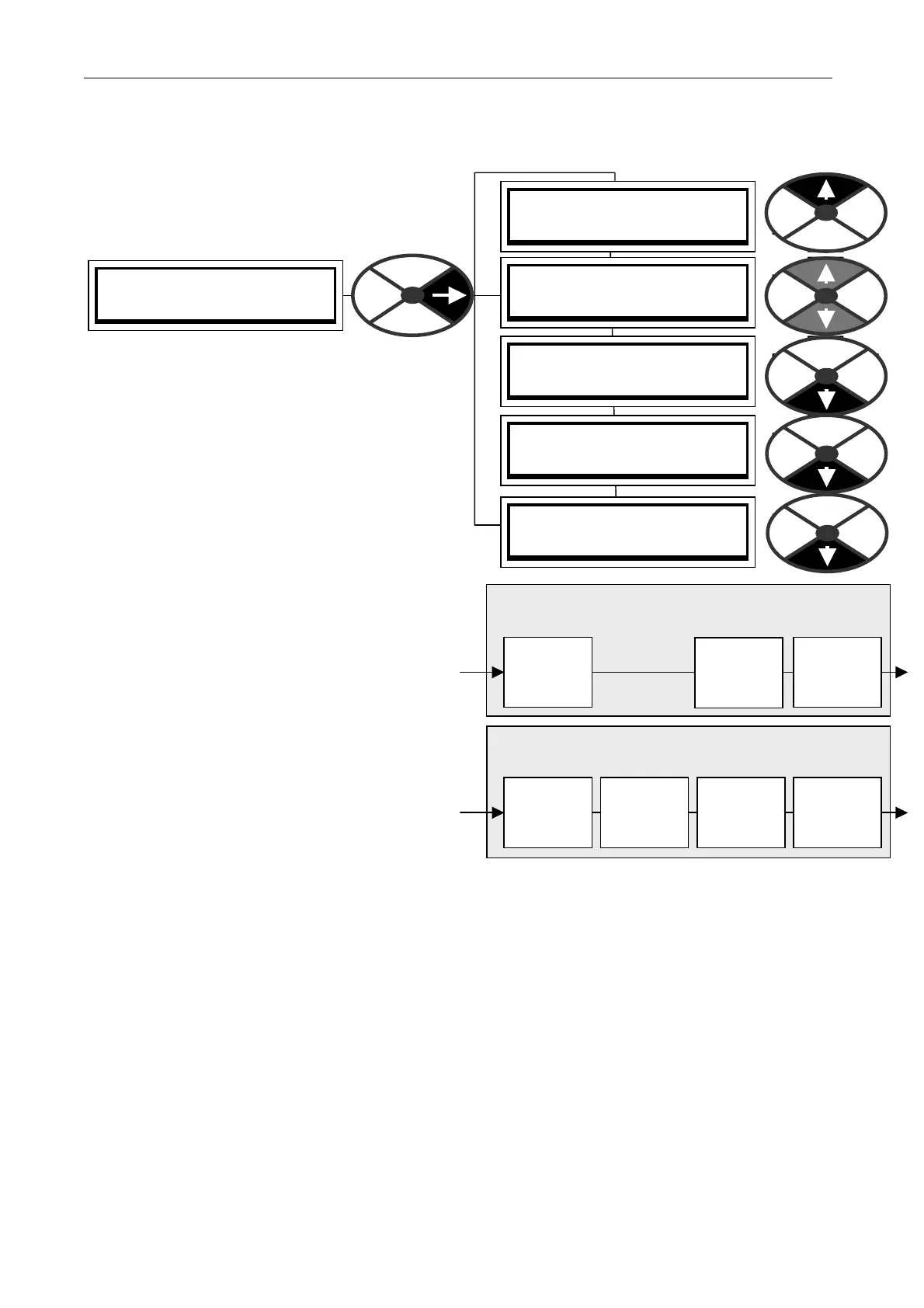

RS232 PORT1 3

REFERENCE EXCH A NGE 4

REFERENCE EXCH A NGE 4

GET FROM

REFERENCE EXCH A NGE 4

189)REF X C SLV RA TIO

REFERENCE EXCH A NGE 4

190)REF X C SLV SIGN

REFERENCE EXCH A NGE 4

191)REF X C SLA VE MON

REFERENCE EXCH A NGE 4

192)REF X C M ASTER MN

10.3 RS232 PORT1 / PORT1 REF EXCHANGE

Allo ws the accurate transmission of parameters

(typically a reference) betw een units with the same

0V. (The slave/master mode is set by PORT1

FUNC TION).

In M ASTER mode the unit initiates high bandwidth

transmission of data, and can also receive data.

In SLA VE mode the unit waits to receive data and

then immediately transmits its ow n data.

Using a GETFROM to source the transmit data, and

and a GO TO to target the received data, within

each PL/X in the chain, gives ultimate flexibility to

the user. See 13.2 Configurable connections.

This function could of course be implemented by using

an analogue signal connection bet w een the drives.

How ever if the system requires greater speed and

accuracy, then this method may be employed.

See 10.1.1 RS23 2 PORT1 / Connection pinouts

for details of the transmit / receive connections.

Daisy chain. When using more than 2 units,

connect RS232 PORT 1 to an external terminal

block to separate the transmit and receive

connections. E.g. from M ASTER transmit to

SLA VE1 receive, and from SLAVE1 transmit to

SLA VE 2 receive etc. The last SLA VE transmit

can connect to the MA STER receive if desired.

With 2 units, the M A STER may use spare SLA VE

blocks. (Send an input, and receive the output).

For information about transmission errors see 8.1.11.15 DRIVE TRIP MESSA GE / Bad reference exchange.

Multi Drive Digital speed locking. Daisy chain using reference exchange and encoder feedback for each drive.

When using this for digital speed accuracy, it is important that the remaining analogue inputs do not inject

small errors into the loop when they are dormant. See 6.7 CH A NGE PARA METERS / SPEED CONTROL.

Useful tips for eliminating unw anted analogue references.

1) The RUN M ODE RA MP output will remain at precisely zero providing the Ramp Hold (T 16) input is

permanently high and the ramp is not permanently preset to a non-zero value. The ramp input may often be

used by line master drives, but in the slave drive the ramp should be disabled using T16. Note that the

incoming digital reference may be passed through the ramp function by re-configuring the appropriate internal

PL/X connections. In this case, the analogue input to the ramp (terminal T4) is disconnected.

2) Analogue input 2 (T2) may be used for inching references. In which case it should be re-connected

via input 1 of the SUMMER 1 apps block, which possesses a deadband function. During normal running, the

terminal is shorted to O V or left open circuit. This ensures no signal passes if the input remains within the

deadband. The analogue inch reference is set above the deadband so as to give the required inching speeds,

forward or backw ard. Selection bet ween analogue inching and absolutely zero is thus automatic. If T2 is not

being used it may be dis-connected, or the UIP2 scaler on PIN 32 2 should be set to 0.0000.

3) Zero input 3 (T 3) using 6.6.7 SPEED REF SUMMER / Speed/Current Reference 3 ratio PIN 67.

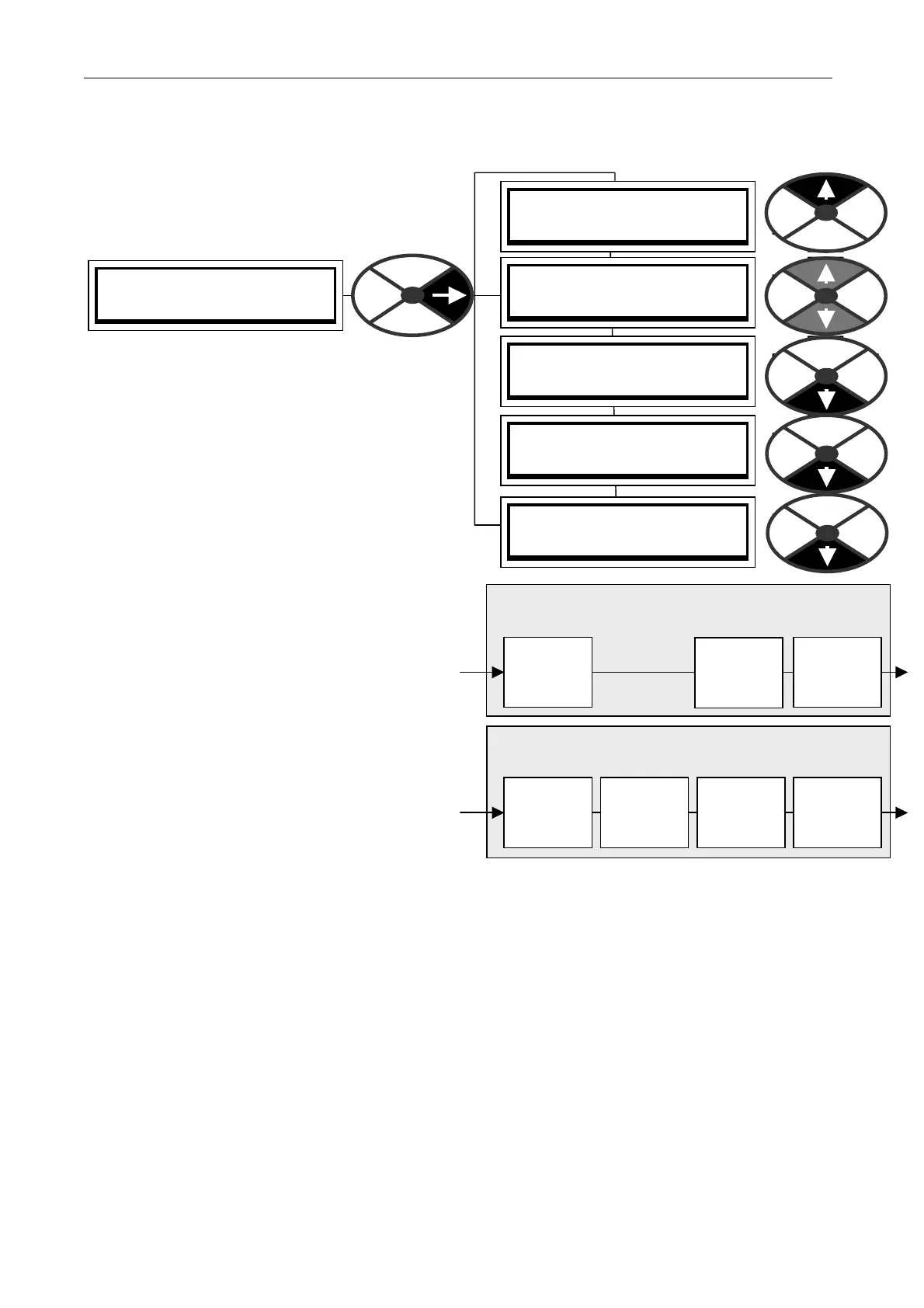

RECEIVE. (In SLA VE mode, receiving data triggers

an immediate transmission sequence)

Ratio

PIN 189

+ /-Sign

PIN 190

Slave

monitor

PIN 191

Ref exch

Slave

Goto

TRA NSMIT. (Initiated by the PL/X in Master mode

or by receiving data in SLA VE mode)

Getfrom

RS232

PORT 1

Master

Monitor

PIN 192

Loading...

Loading...