Chapter 5: Routine Operational Procedures

5/23

Operators & Maintenance Manual GENIUS Compact Version UK 0.1 © BESTnv

BESTnv Industrial Research BV, Marinus van Meelweg 20, 5657 EN, EINDHOVEN, THE NETHERLANDS

General tel. +31 (40) 292 2622 - Service tel. +31 (40) 292 2620 - Fax. +31 (40) 292 2633 - Email: service.BESTnv@bestnv.com

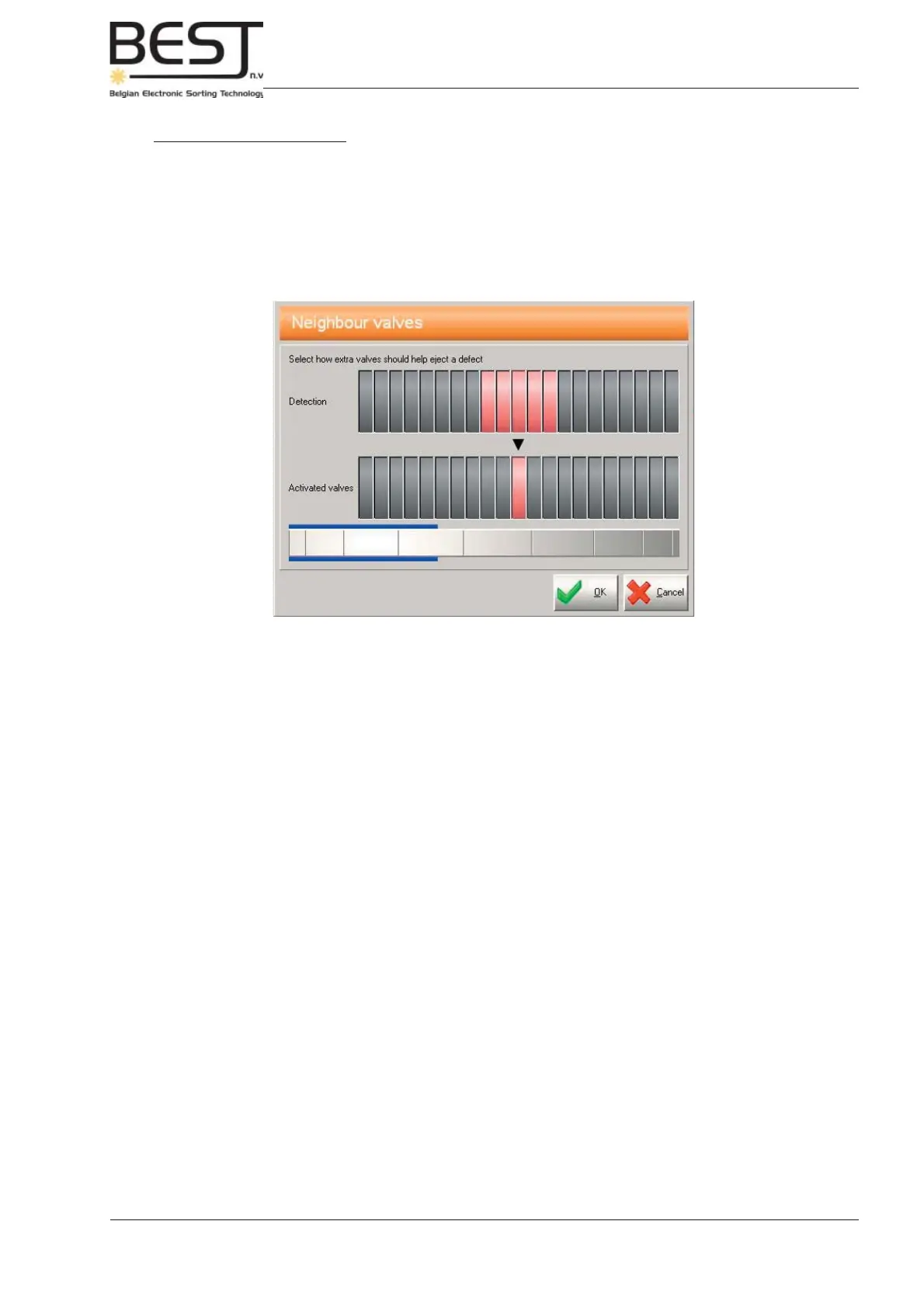

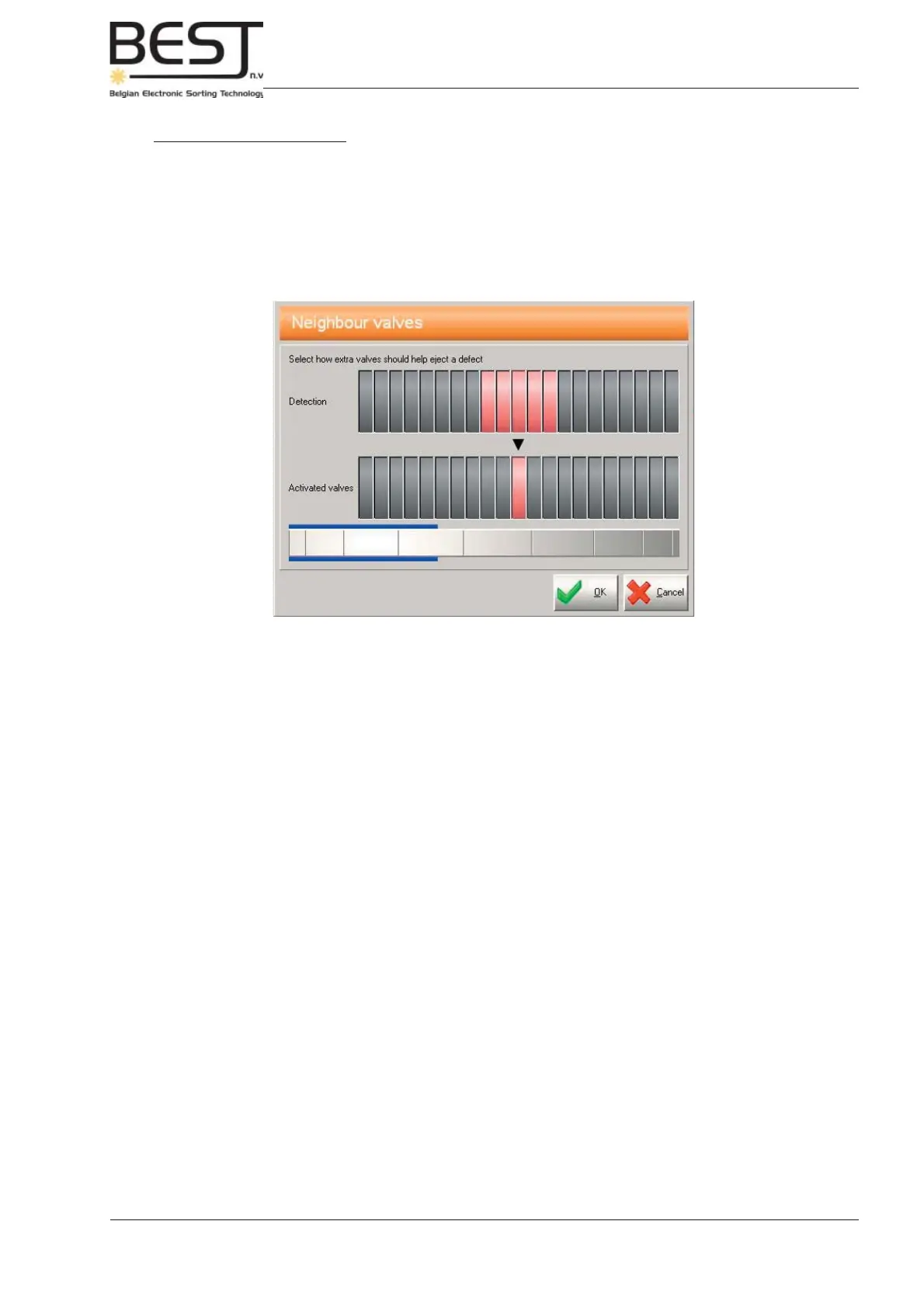

Negative Overlap (-1 to -10):

The value - 2 means that two less air gun valves at both sides of the detected defect will fi re, with a

minimum of 1 air gun that will always fi re.

For example: if a large defect is detected that falls within the zone of 5 air gun valves, only the middle

valve will fi re. If a defect only falls in the zone of 1 air gun valve, it will still fi re.

This can be useful when sorting very light products, to avoid too much false reject.

Always keep the following basic rules in mind when setting the overlap (Eject Mode):

- Always keep the overlap as small as possible: the bigger the overlap, the more good

product will be targeted along with the defect.

- For certain large or long products (potatoes, whole carrots, etc. ...) a bigger overlap may

be necessary, in order to be sure the defect will be blown out, even when it is situated at an

extremity of the product.

Loading...

Loading...