MAINTENANCE & FAULT FINDING

Sensor test on a V200

4 Issue 1January 2008 (211)

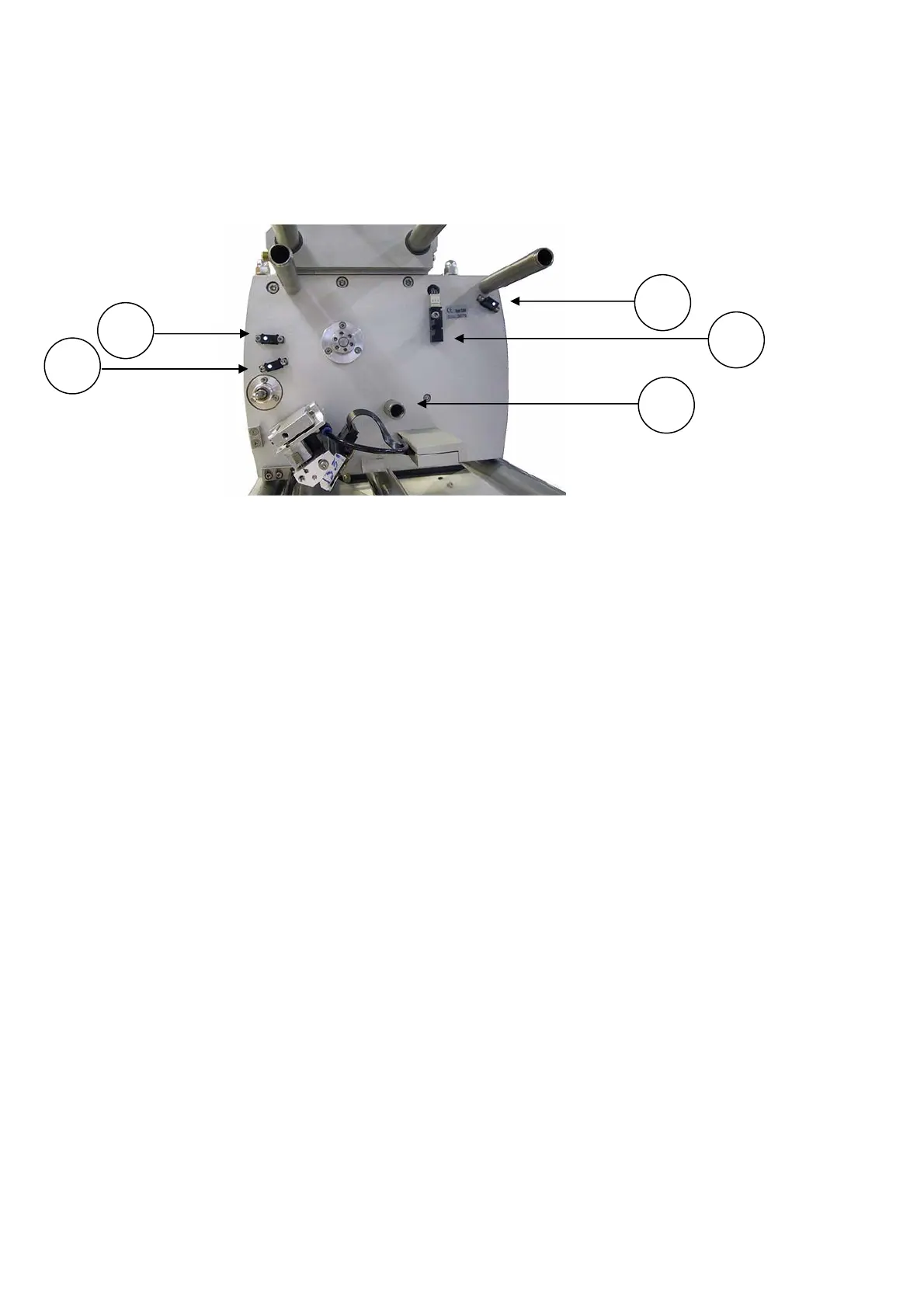

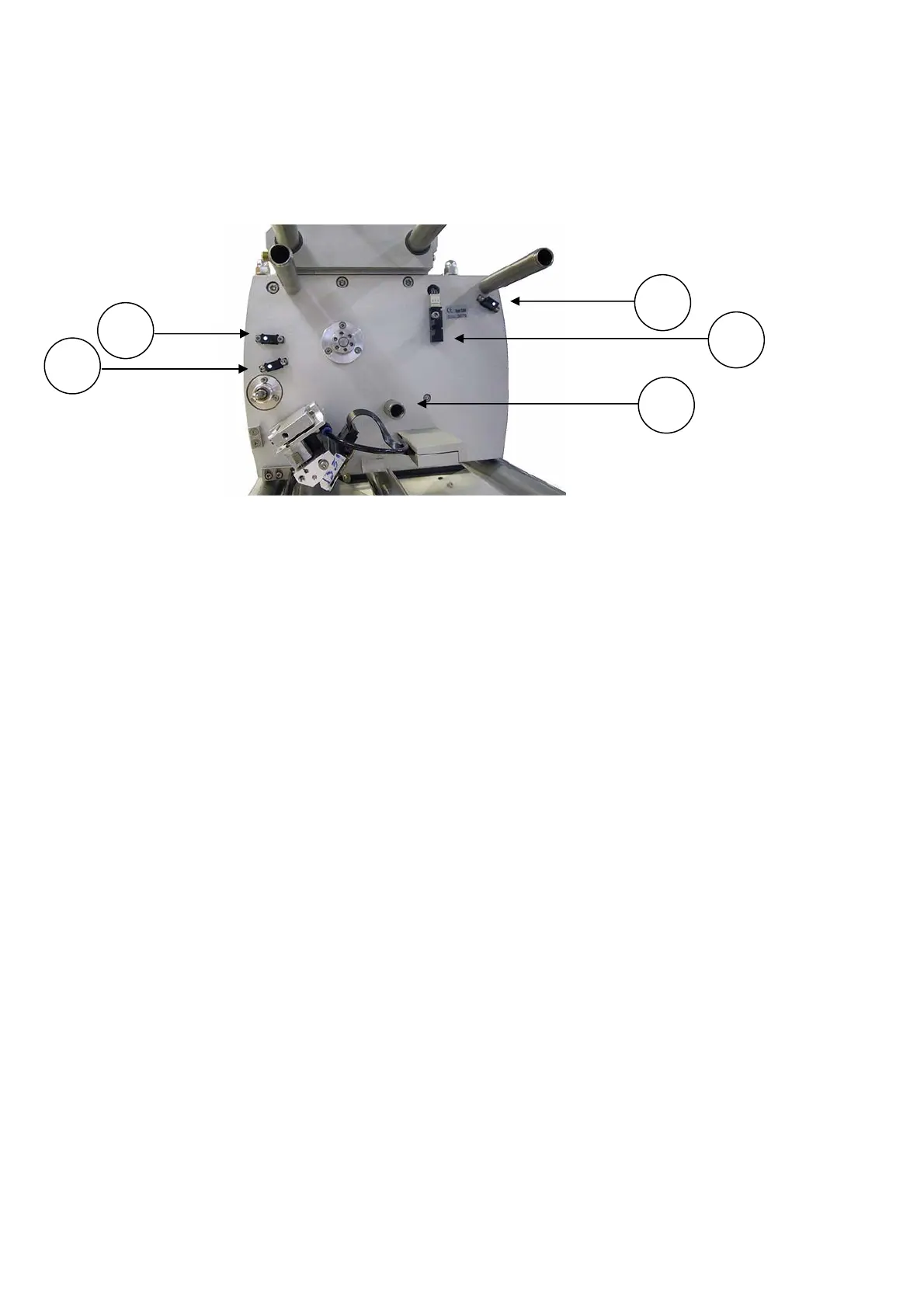

3

4

1

2

5

(1) Start Winder

activated by the dancer arm (in the casette) the winder motor is

bon roll.

(2) Stop Winder

tensions the ribbon, the dancer arm moves down until the Stop

inue to run

sor. A failing

ning

e amount of unused ribbon.

ted for every X prints, where X is

determined by the actual printed message. Usually 2-6 prints.

(5) Cassette open

If this sensor fails the printer may report “Printer Open”.

Check the sensor by opening and closing the cassette.

When this sensor is

engaged. If this sensor fails, the ribbon will not be wound onto the used rib

As the winder motor

Winder sensor is reached. If this sensor fails, the winder motor will cont

and eventually time out.

(3) Ribbon Alarm

If the ribbon breaks, a dancer arm will activate the Ribbon Alarm sen

sensor results in a ribbon break not being detected immediately.

(4) Ribbon War

The Ribbon Warning sensor is used to measure th

If this sensor fails, a ribbon error will be presen

2786

Loading...

Loading...