OPERATION

Run Settings Technical

4 Issue 1January 2008 (161)

the application itself, the user will

is menu.

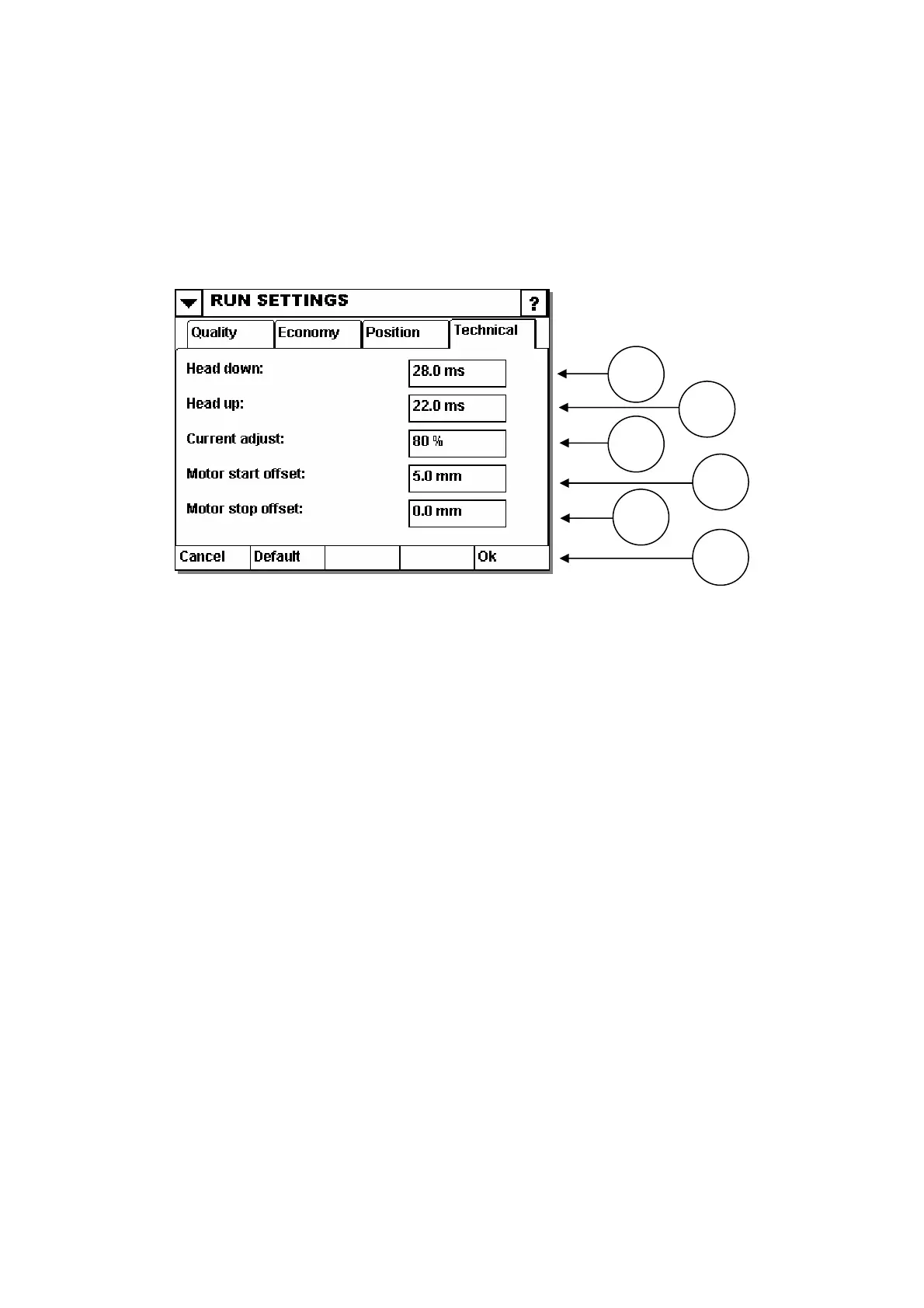

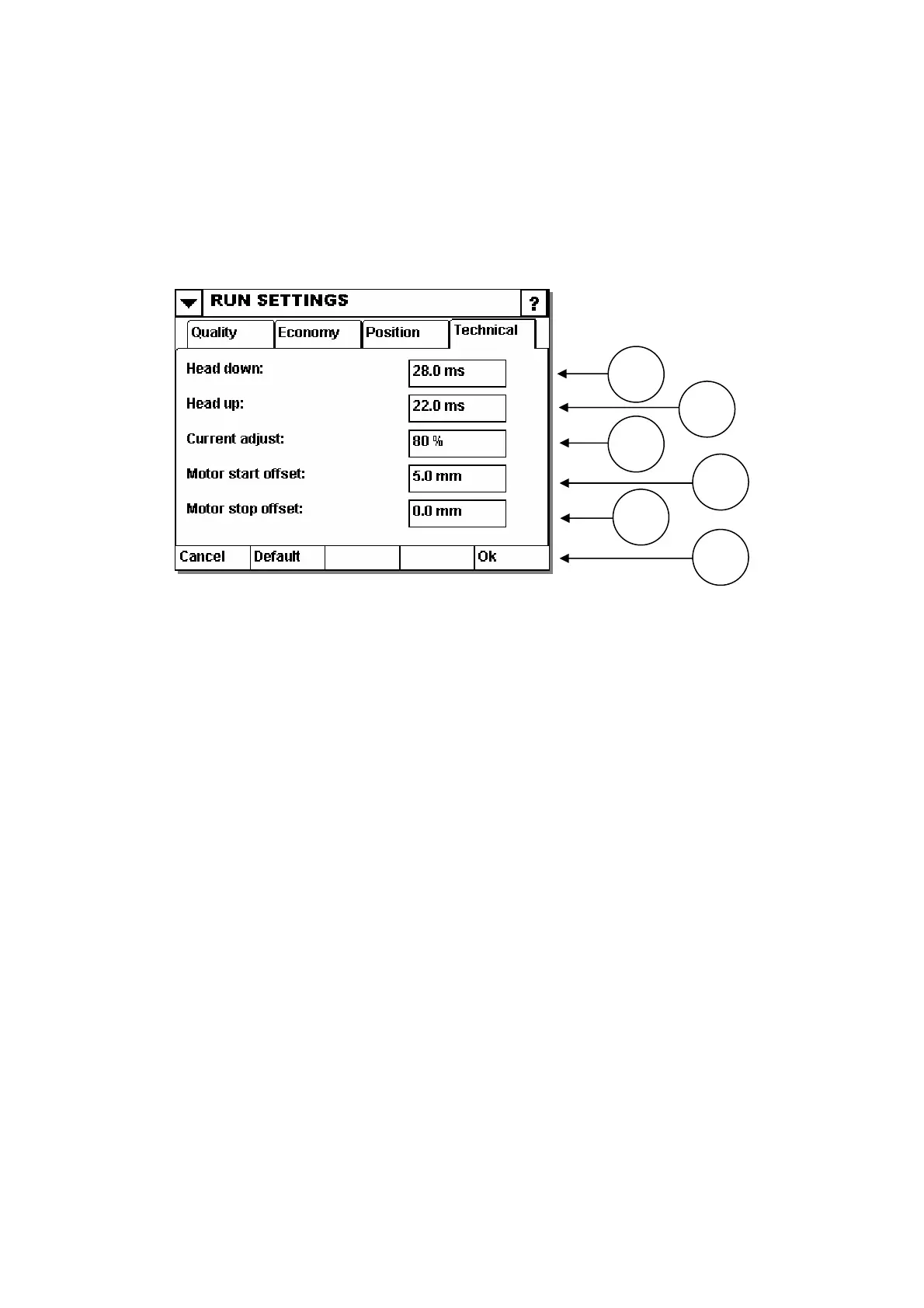

Below is an illustration of the ”Technical” tab screen:

d must be

lve, thus

signal until

compensate for this delay, the “Head Down”

ier, i.e. the number

defines for this setting is the number of milliseconds earlier that

e print is missing, it is usually because this

w.

ds

d must be

There is normally a short (mechanical) delay from the time of sending the signal until

the print head is physically raised. To compensate for this delay, the “Head Up” value

can be increased, thus causing the signal to be transmitted earlier. If the last part of the

print is missing, it is usually because this setting is too high.

The normal value of this setting is default set between 10 and 22 milliseconds

depending of printer type.

The last tab in “RUN SETTINGS” is the “Technical” tab.

As the V200 calculates the optimum settings for

never have to make any great adjustment to th

1

2

3

(1) Head Down

An air valve controls the V200’s print head movement. When the print hea

lowered, i.e. at the start of a print, the V200 software sends a signal to this va

lowering the print head.

There is normally a short (mechanical) delay from the time of sending the

the print head is physically lowered. To

value can be increased, thus causing the signal to be transmitted earl

of milliseconds the user

the signal will be sent. If the first part of th

setting is too lo

The normal value of this setting is default set between 25 and 30 millisecon

depending on printer type.

(2) Head up

An air valve controls the V200’s print head movement. When the print hea

raised, i.e. at the end of a print, the V200 software sends a signal to this valve, thus

raising the print head.

6

5

4

2786

Loading...

Loading...