MAINTENANCE & FAULT FINDING

) 27864 Issue 1 January 2008

by

ming a lubrication of the re-winder and adjusting the brake system on the un-

Note: Tension control does not apply for the V200 printers

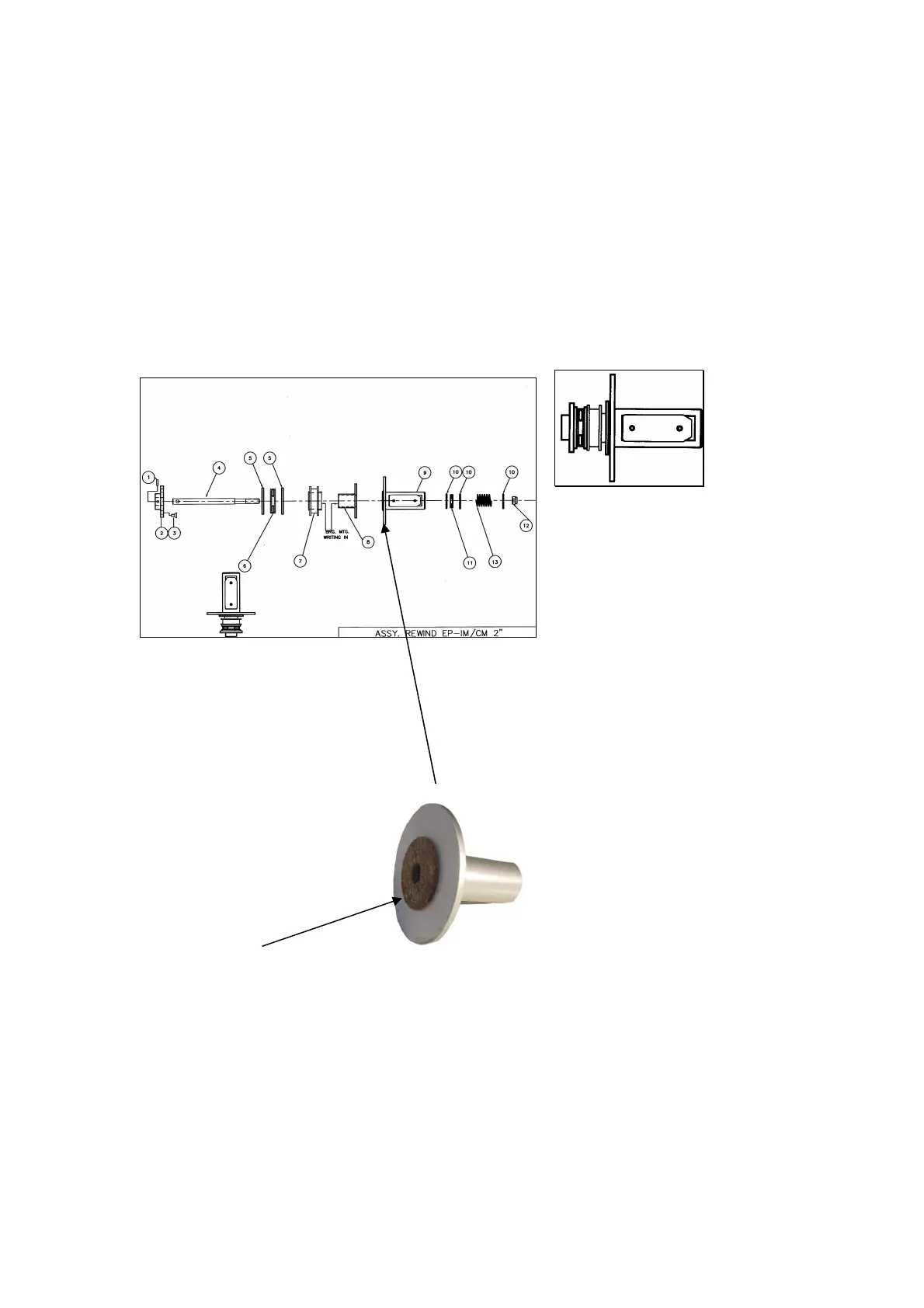

Rewind assembly

TENSION CONTROL

At regular intervals it is recommended to verify the tension of the ribbon

perfor

winder.

Lubrication of the re-winder

VAS2004

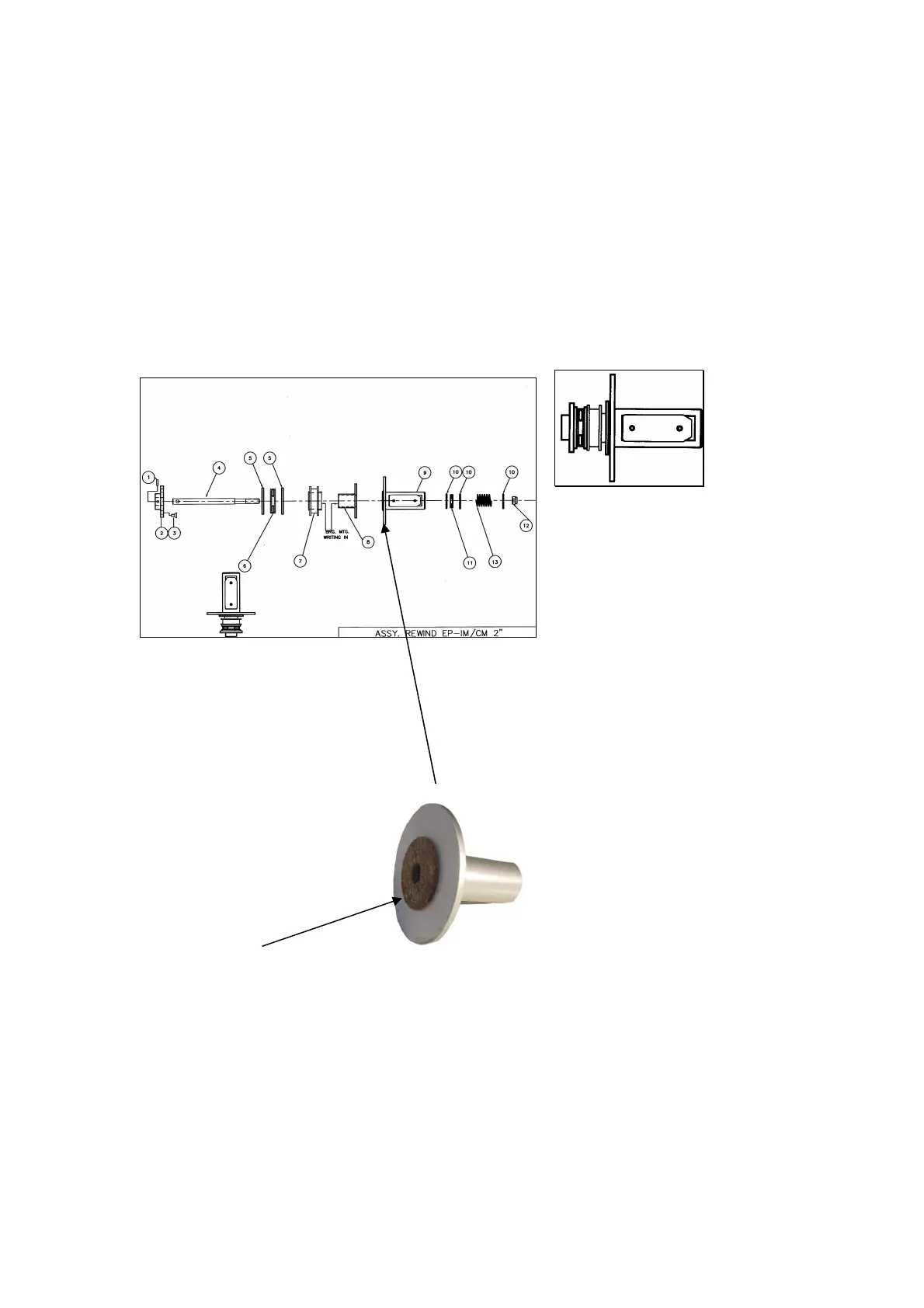

Remove the parts as shown, grease the cork wascher

as explained below, and be sure to re-assemble all

order.

Apply a small amount

ricant on the cork

and remove all redundent

lubricant before assembling.

Cork washer

Recommended

maintenance period:

Every 3 months or in

accordance to the needs.

parts in the reverse

washer, of silicon lub

(

170

Loading...

Loading...