Epson Artisan 800/Epson Stylus Photo PX800FW/TX800FW/Epson Artisan 700/Epson Stylus Photo PX700W/TX700W

Adjustment Items and Overview

https://www.manualsbooks.com

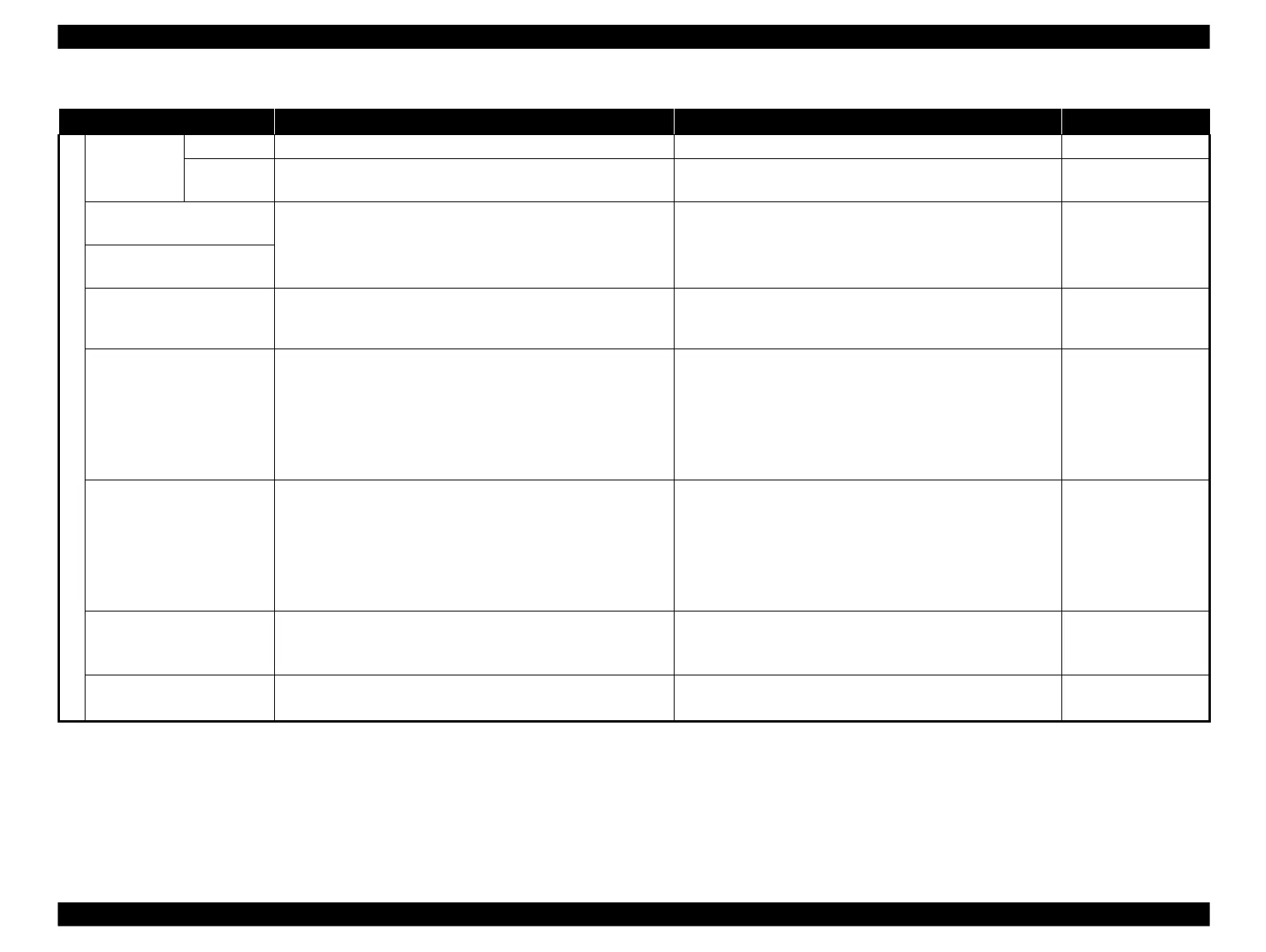

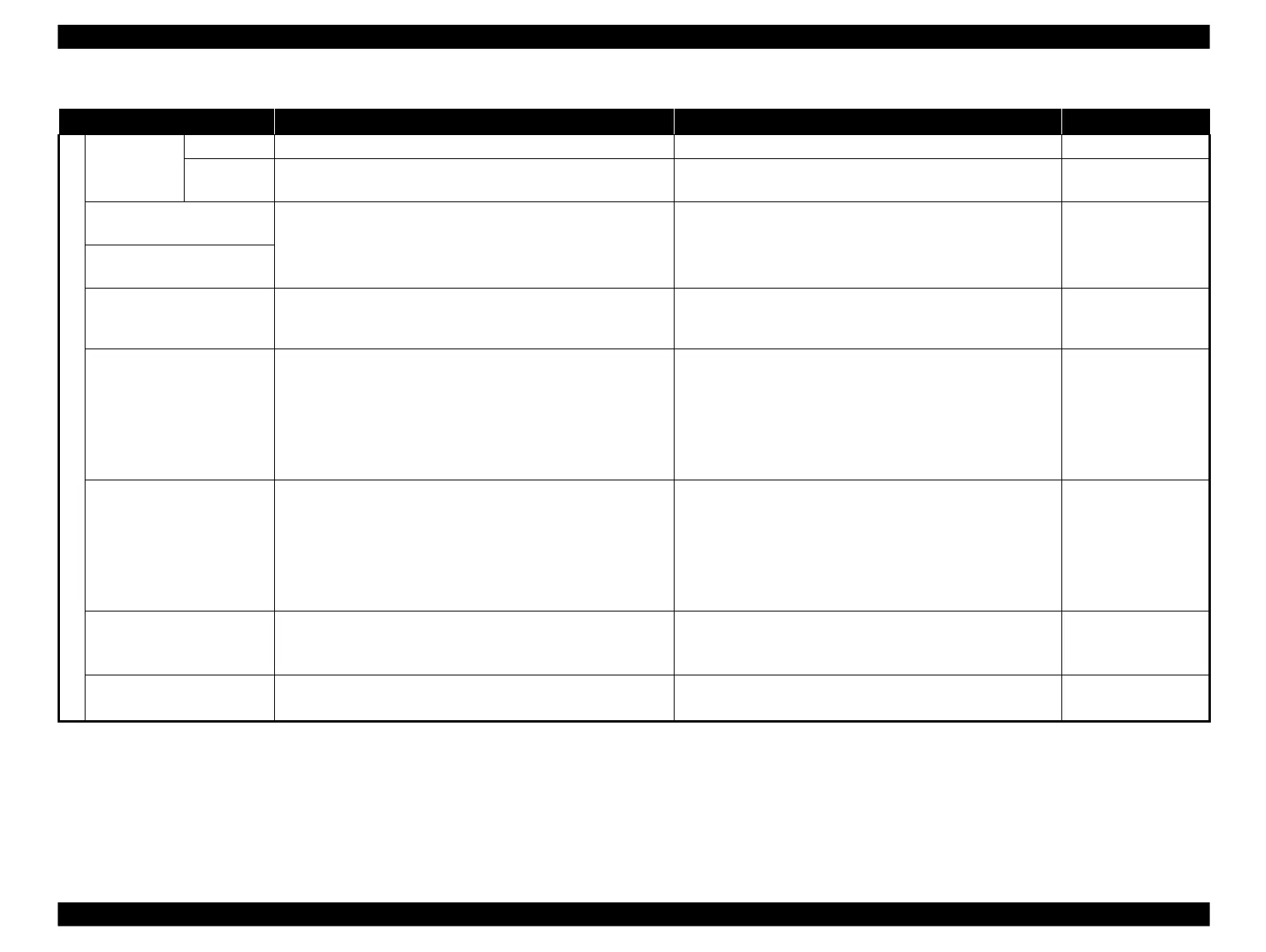

Table 5-1. Adjustment Items

The PF deterioration offset counter is reset.

Reset the PF deterioration offset counter.

The maximum PF deterioration offset counter is entered.

Enter the maximum PF deterioration offset counter (10,000).

CR motor heat protection

control

This is used to correct variations of motors characteristics.

Select the part(s) you replaced on the Adjustment Program. The

program will automatically enter a proper correction value onto

the printer.

PF motor heat protection

control

This corrects errors in paper feed caused by variation of

mechanisms and media characteristics.

A PF adjustment pattern is printed. Examine the printout patterns

and select the value for the best pattern. The correction value is

registered.

This adjustment is made to ensure both high print quality (less

banding) and high print speed in the target print mode by carrying

out 1-path printing correcting ink drop amount for each raster

mode.

Print the adjustment pattern to be scanned by a specified scanner.

According to the scanned result, a correction value is

automatically calculated and stored into the serial flash ROM on

the main board. The correction value is applied when printing in

the corresponding mode. For more details, see 5.2.10 “ Banding

Reduction System (BRS) Adjustment / Paper Feed Amount

Profile (PFP) Correction (p230) ” .

• Adjustment Program

• Specified Scanner

• PFP base scale

This adjustment is made to ensure both high print quality and high

print speed in the target print mode by measuring the paper feed

errors at various points and calculating a correction value for each

of the points.

Print the adjustment pattern to be scanned by a specified scanner.

According to the scanned result, a correction value is

automatically calculated and stored into the serial flash ROM on

the main board. The correction value is applied when printing in

the corresponding mode. For more details, see 5.2.10 “ Banding

Reduction System (BRS) Adjustment / Paper Feed Amount

Profile (PFP) Correction (p230) ” .

• Adjustment Program

• Specified Scanner

• PFP base scale

To check if the Cover open sensor operates normally.

See 5.2.8 “ Case Open Sensor Check (p226) ” for information on

how to check.

• Adjustment Program

• Thickness Gauge

0.9mm, 3.0mm

To check the joint section for leakage when disconnecting the joint

between the printhead and the ink tube.

See the video manual; separately distributed, for the details.

• Leak Check jig

• Air release jig

Loading...

Loading...