Operating Procedures: Patterning

C O N F I D E N T I A L – FEI Limited Rights Data5-54

Note

PMMA – PolyMethylMetaAcrylat

Application Files Examples

The non-gas assisted milling – the Si New application file:

• Beam Type: Ion

• Dwell Time (the time the beam spends on a single pixel per pass): 1.0 e

-6

s

• Overlap (the beam diameter overlap): 50%

• Volume per Dose (the amount of material volume removed per charge): 0.27 e

-9

m

3

/nC

This is called sputter rate in previous dual beam tools.

The gas-assisted application file – the Tungsten application file:

• Beam Type: Ion

• Dwell Time: 250 e

-9

s

• Overlap: -50%

• Volume per Dose: 0.025 e

-9

m

3

/nC

• Refresh Time (the waiting time after each pattern pass): 0

• Blur (beam defocus – to increase deposition for large areas): 0

If the overlap is positive the mill time can be calculated based on the volume per dose parameter and the beam

current:

For example, create a filled box pattern (5 × 5 × 2) µm (X × Y × Z, the desired material volume to be milled is

50 µm

3

) and choose 0.5 nA, which is 0.5 nC/s.

Therefore:

Doubling the Z size – the desired volume would be twice larger and the milling time twice longer, doubling the

beam current cuts milling time by half.

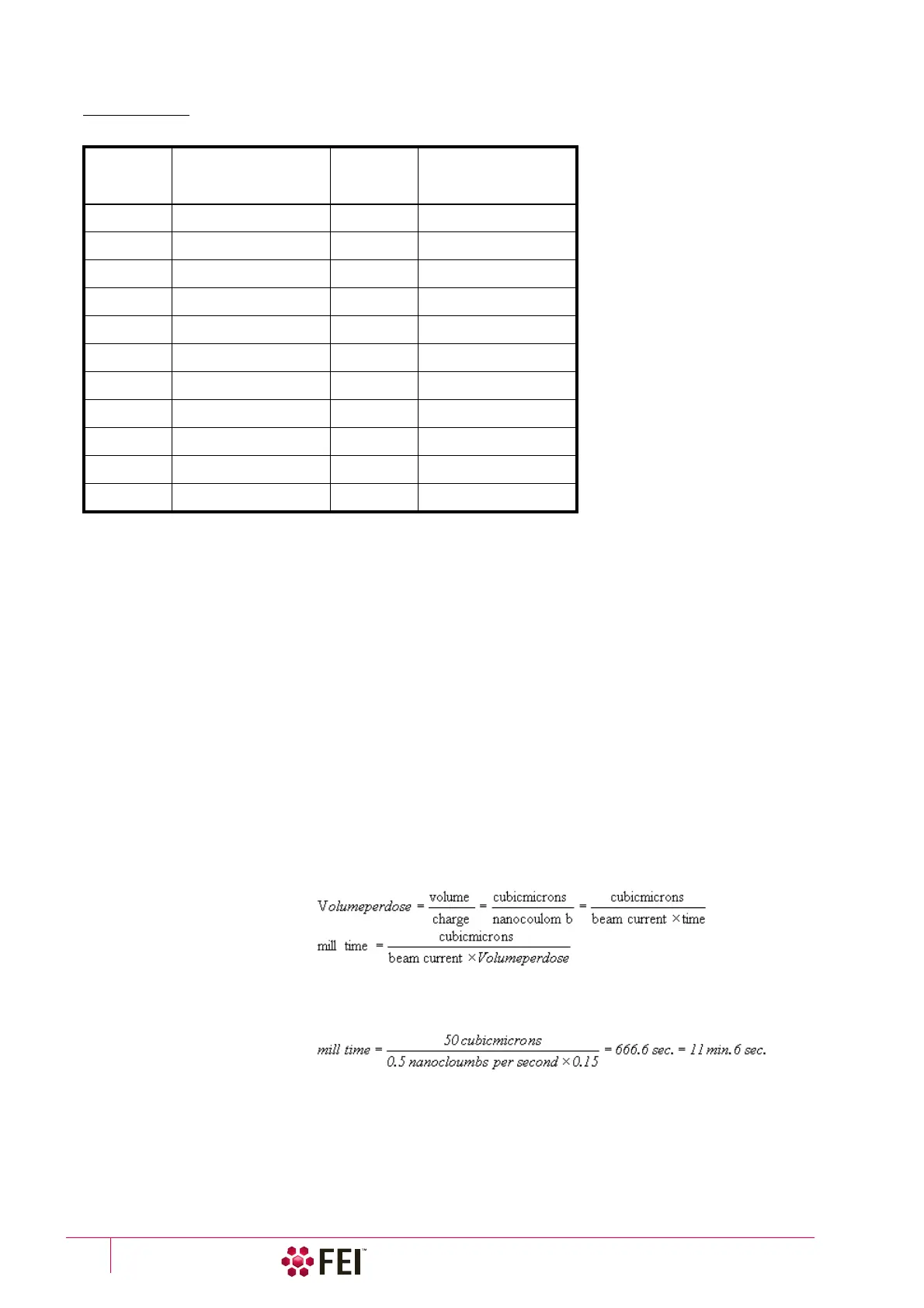

Table 5-7

Material Sputter Rates at 30 kV

Material

Volume per Dose

[µm

3

/ nC] Material

Volume per Dose

[µm

3

/ nC]

C 0.18 Au 1.50

Si 0.27 MgO 0.15

Al 0.30 SiO

2

0.24

Ti 0.37 Al

2

O

3

0.08

Cr 0.10 TiO 0.15

Fe 0.29 Si

3

N

4

0.20

Ni 0.14 TiN 0.15

Cu 0.25 Fe

2

O

3

0.25

Mo 0.12 GaAs 0.61

Ta 0.32 Pt 0.23

W 0.12 PMMA 0.40

Loading...

Loading...