Operating Procedures: Patterning

C O N F I D E N T I A L – FEI Limited Rights Data5-48

Patterns Processing

Once a pattern shape has been drawn, it can be modified (see Shapes editing above).

Importing / Exporting Patterns

User created patterns may be imported or exported (saved) via

the File menu / Import or Export / Patterns item. The saved file

(.ptf) contains all parameters found at the Patterning property

editor (Basic / Advanced) for all patterns drawn in the active

display. Six (for each beam) toolbar Pattern Presets (labeled p#)

can be individually assigned to any of these .ptf file.

Right-clicking on the selected button calls up the menu:

• Apply item – selects appropriate button (highlighted with an

orange background) and starts the patterning with the preset

parameters (the same as clicking on the button directly)

• Edit item – opens the Assign Pattern File (.ptf) window to assign

desired parameter file to a selected button

The toolbar Pattern Presets assignment to the particular .ptf file

can be saved or loaded by the File menu / Export or Import /

System Parameters item.

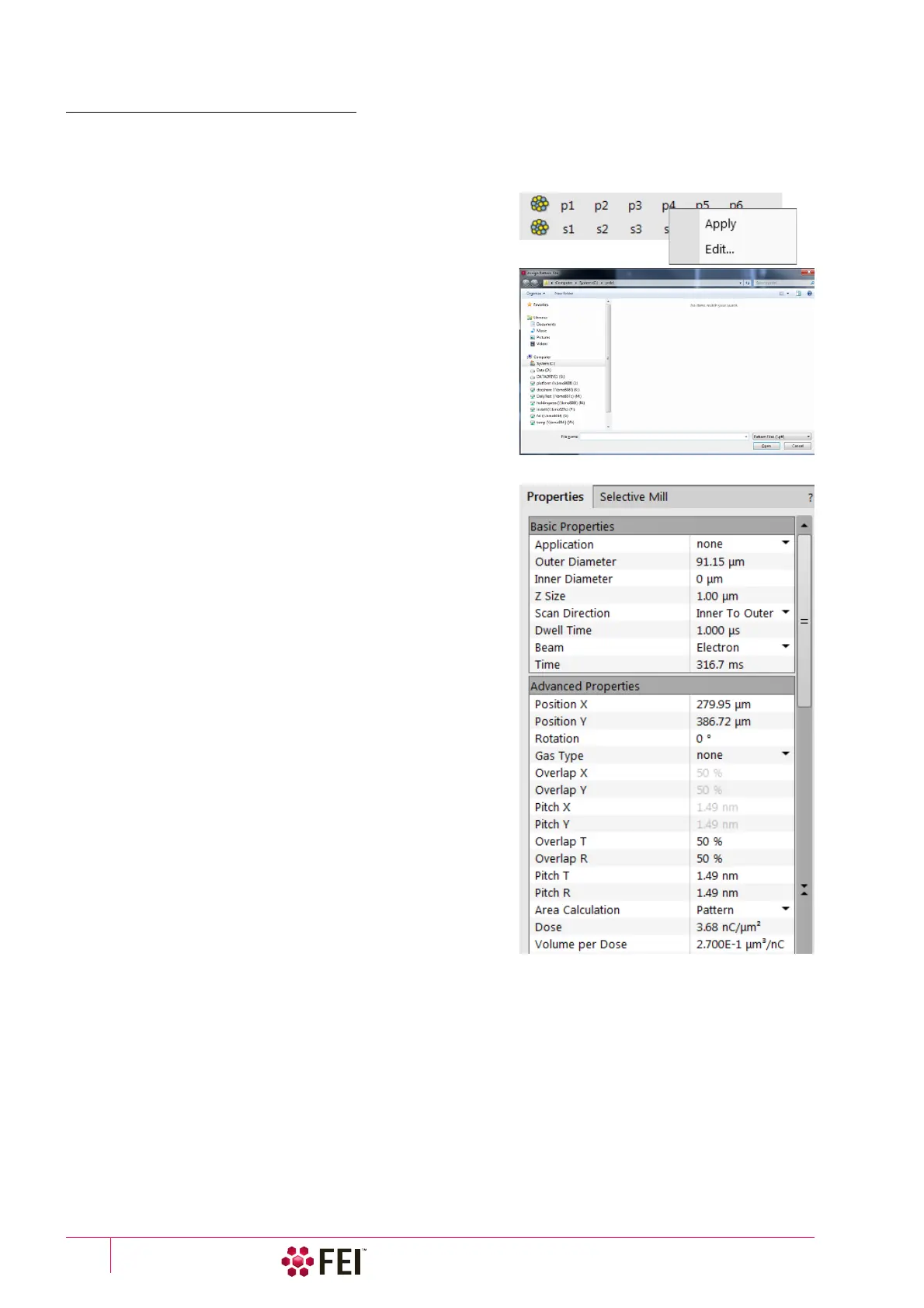

Property tab Module

A certain pattern can be selected from the list box with many

associated parameters which can be set via the Property module:

• Application – clicking on the value slot enables a down arrow

bringing a drop down list of applications. Choosing the

required one sets the subsequent properties.

• X / Y / Z size – dimensions of the pattern

• Scan Direction – scan movement direction (Bottom to Top; Top

to Bottom)

• Dwell Time – a time the beam spends on a single pixel per pass

(rounded to a multiple of 25 ns).

• Beam – the beam used for patterning

• Time – required to process this pattern

• Position X / Y of the pattern relative to the origin (the display

center)

• Rotation of the patterns (the positive direction is clockwise)

• Gas Type – the gas to be used to process the pattern (or None if

no gas is to be used). This determines the pattern color

onscreen.

• GasDutyCycle –

• GasNeedlePosition –

• OverlapX / Y – sets the beam diameter overlap. The value of

the overlap can be positive or negative depending on a

particular application. The overlap parameter influences the

Area Calculation and the Dose.

• PitchX / Y – sets the pitch between two spots

• Area Calculation – defines how the patterning area will be calculated in order to get the most accurate value of

the Dose. This value is related with the OverlapX/Y. The Pattern (default) / Array are set for positive / negative

overlaps.

• Dose –

• Volume per Dose – the volume of material that is removed per charge

• Saturation Sputter Rate – the maximum linear sputter rate for a given gas. For Gas = None this is 0 (actually not

used).

• Refresh Time – the minimum loop time that must at least elapse before the next pass, so that the adsorbed gas

can be refreshed

• Loop Time – the time required for a single pass (read only)

• Area – the surface area of the pattern (read only)

Loading...

Loading...