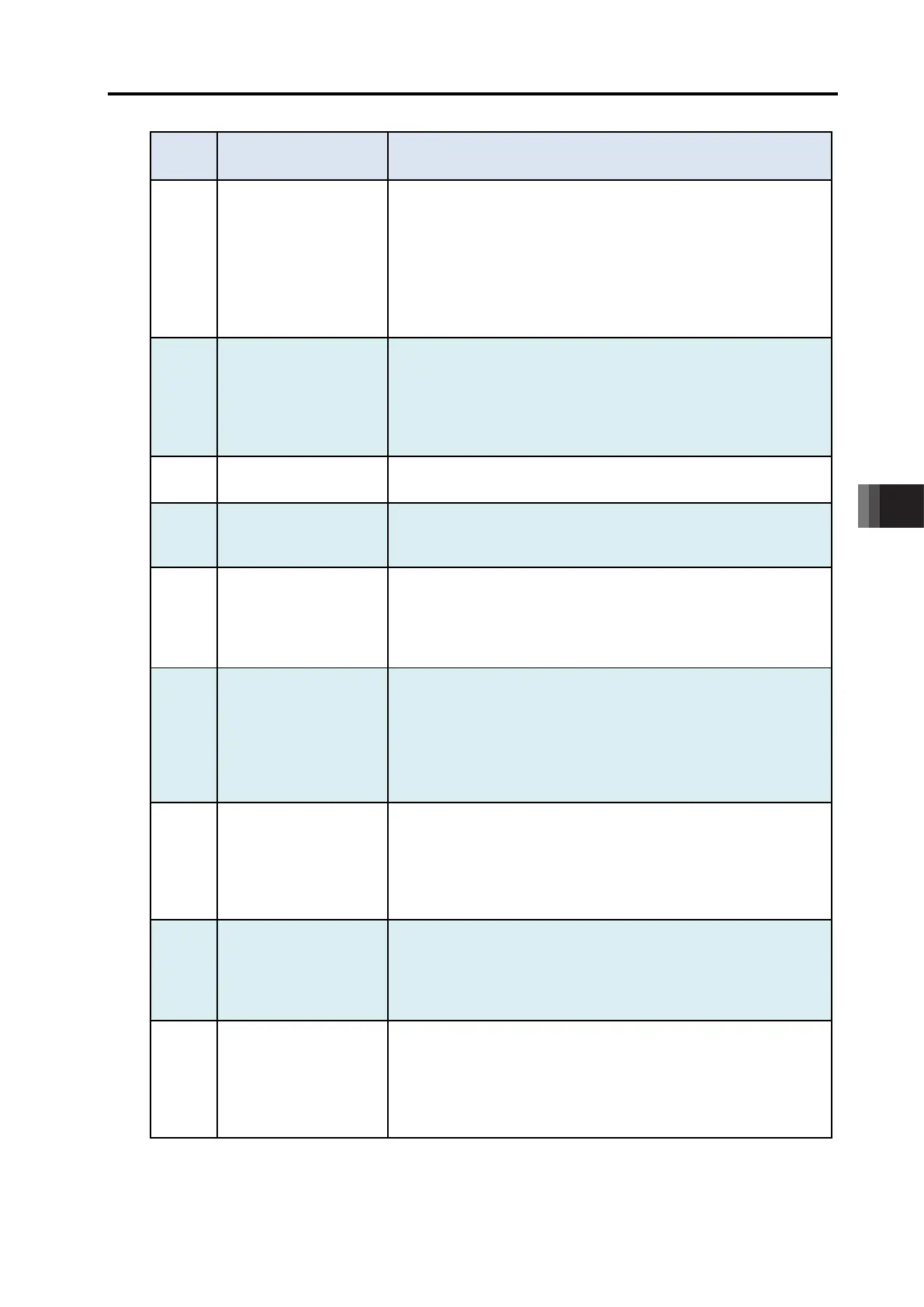

8. Troubleshooting

8.3 About Alarms

8-27 ME0342-4B

Cause : The data sent from the controller was not received properly

by the encoder side.

1) Encoder cable is partially disconnected, or connector is not

connected properly.

2) Influence from noise.

3) Failure of communication IC mounted on the encoder circuit

board.

4) Failure of communication IC mounted on the driver unit

circuit board.

Countermeasure : 1) Confirm that there is no failure in the cable and

connector coupler.

2) Try turning OFF power to all peripheral devices

and moving only the controller

error is generated, the culprit may be noise.

Take measures against noise.

3) or 4) is the case, replace the motor unit or

0E5

Encoder receipt error

Cause : This shows the data was not received in normal condition

from the encoder side to the controller.

1) Breakage of encoder cable or connection error on

connectors

(If the detail code in the alarm list of the teaching tool is

0002

H

.)

2) Effect of noise (Detail Code 0001

H

)

3) A faulty part inside the actuator (communication part).

4) A faulty part inside the controller (communication part).

5) Initialization of battery-less absolute encoder is incomplete

(Detail Code 000A

H

)

6) Error occurred in communication with battery-less absolute

encoder (Detail Code 000C

H

)

Countermeasure : 1) Check if any wire breakage on a connector and

the condition of wire connections.

2) Interrupt the power to the peripheral equipment

and activate only the actuator. If any error does

not occur, it might be caused by noise. Take

proper measures against noise.

3), 4) or 5) if it is the cause, is necessary to replace

the actuator (motor part) or controller.

6) Check a breakage of encoder cable and

connection on the connectors. For the high-

resolution battery-less absolute encoder, check

the capacity of 24V DC power supply and

connection on power supply wiring.

Cause : Error status was received in initial communication with

battery-less absolute encoder

Countermeasure : Reboot the power and conduct an absolute reset

(home-return operation).

Replace the motor unit in case the condition would

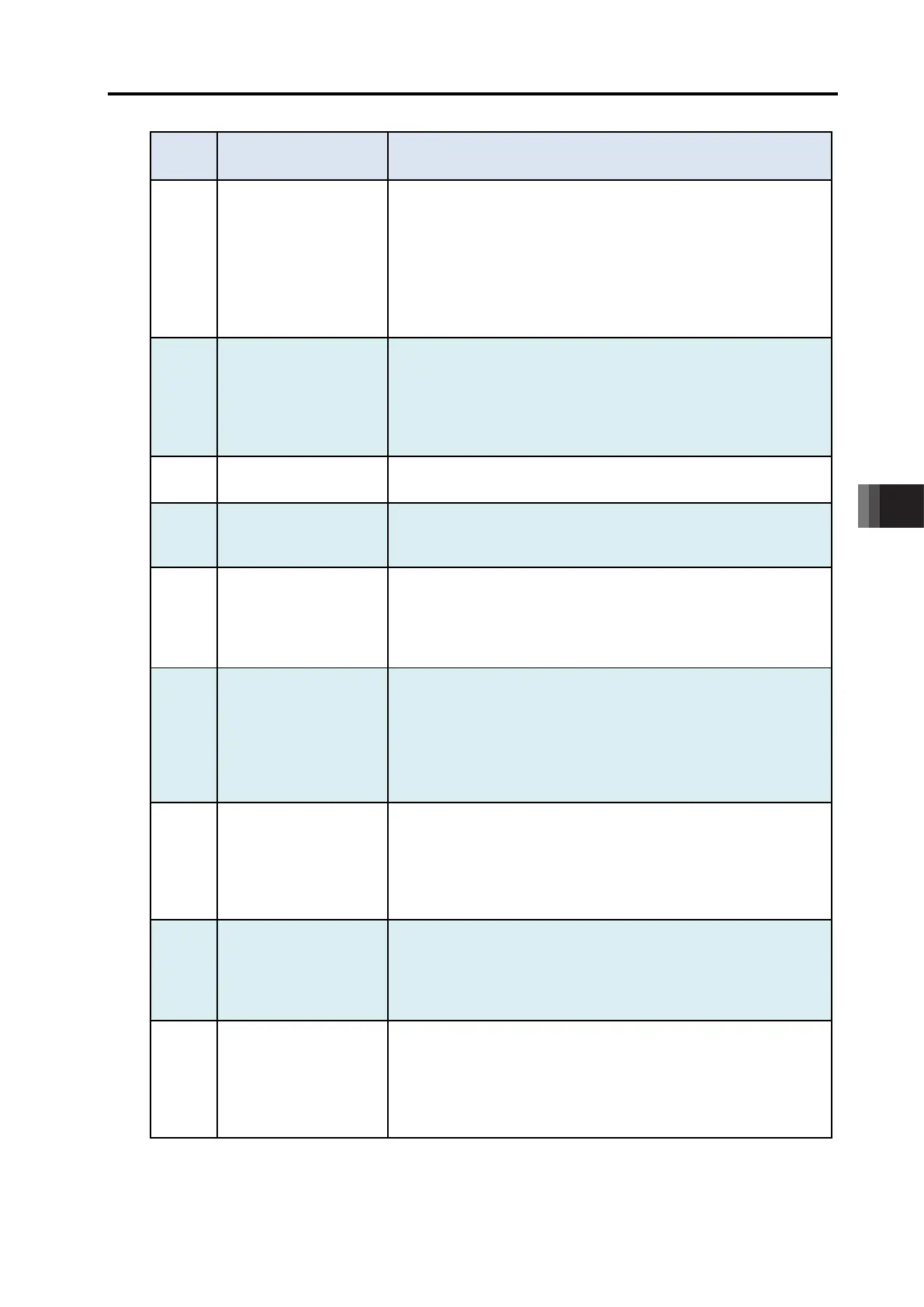

8.3 About Alarms

ME0342-4B 8-28

Alarm Name Alarm Name

disconnection

Cause : The encoder signal cannot be detected normally.

1) Disconnection of the actuator connection cable, actuator

side attached cable, or connector connection failure.

2) Failure of the encoder itself.

Countermeasure : 1) Check for any wire breakage on a connector and

inspect the condition of the wire connections.

2) If there is no cable malfunction, encoder failure

0EB

Battery-less absolute

encoder error detected

Cause : Battery-less absolute encoder cannot detect location

information normally.

Countermeasure : Check for any wire breakage on a connector and

inspect the condition of the wire connections.

If there is no cable malfunction, encoder failure

Cause : Error detected in field network circuit board.

Countermeasure : Check the parameter settings.

detected

Cause : Field network circuit board could not be detected.

Countermeasure : Reboot the power. Replace the controller incase

the phenomenon would not be solved.

Cause : The PCB is not applicable for the connected motor in the

startup check.

Countermeasure : The actuator may not match the controller. Check

the model.

Should this error occur, please contact IAI.

0F5

Non-

verify error

Cause : Unmatch was detected when the data was written to the non-

volatile memory and comparison (verification) was made to

see if the data inside the memory matches with the written

data. (Failure of non-volatile memory)

Countermeasure : If the same phenomenon occurs even after the

power is rebooted, it is necessary to replace the

Non-volatile memory write

timeout

Cause : There is no response within the specified time during the data

writing to the non-volatile memory. (Failure of non-volatile

memory)

Countermeasure : If the same phenomenon occurs even after the

power is rebooted, it is necessary to replace the

destruction

Cause : Abnormal data was detected by non-volatile memory check at

startup. (Failure of non-volatile memory)

Countermeasure : If the same phenomenon occurs even after the

power is rebooted, it is necessary to replace the

0FA CPU error

Cause : CPU is not operating normally.

1) CPU malfunction.

2) Malfunction caused by noise.

Countermeasure : If the same phenomenon occurs even after the

power is rebooted, it is necessary to replace the

Loading...

Loading...