6. Parameter

6.1 Parameter

6-57

ME0342-4B

[How to Figure out Setting Value]

For the lead and the encoder pulse count of each actuator, refer to [9.4.1 Specifications of

Actuators].

For Linear Axis

Lead Length × Numerator of Electronic Gear (Parameter No.65) × 2,000

Encoder Pulse Count × Denominator of Electronic Gear (Parameter No.65) × Min. Use Velocity

(Note2)

For Rotary Axis

360 × Gear Ratio of Rotary Axis × Numerator of Electronic Gear (Parameter No.65) × 2,000

Encoder Pulse Count × Denominator of Electronic Gear (Parameter No.65) × Min. Use Velocity

(Note2)

Set the rounded up value when the calculation result is greater than 1.

There is no need of change from the default when the calculation result is 1 or smaller.

Note 1 It is necessary to make a change when a low velocity operation with the movement

amount for 1ms below 2 pulses.

Note 2 Minimum use velocity ... The most slow velocity available for operation

[104] Network Number (Parameter No.188)

No. Name Unit Input range

Default initial value setting

188 Network Number - 1 to 239 1

This parameter is exclusively used for the Field Network (CC-Link IE Field).

Refer to separate volume, [CC-Link IE Field Instruction Manual (ME0389)]

[105] Select Load Monitoring Symbol (Parameter No.198) …Pulse press only

No. Name Unit Input range

Default initial value setting

198

Select Load Monitoring

Symbol

0: Compression Load

1: Tension Load

0

It is a parameter that enables to select the symbol of the monitoring values in accordance with

the condition to use. Set it to "0" and the direction to compress should be set as the positive

value, and set it to "1" and the direction to apply tension should be set as the positive value for

monitoring.

T =

T =

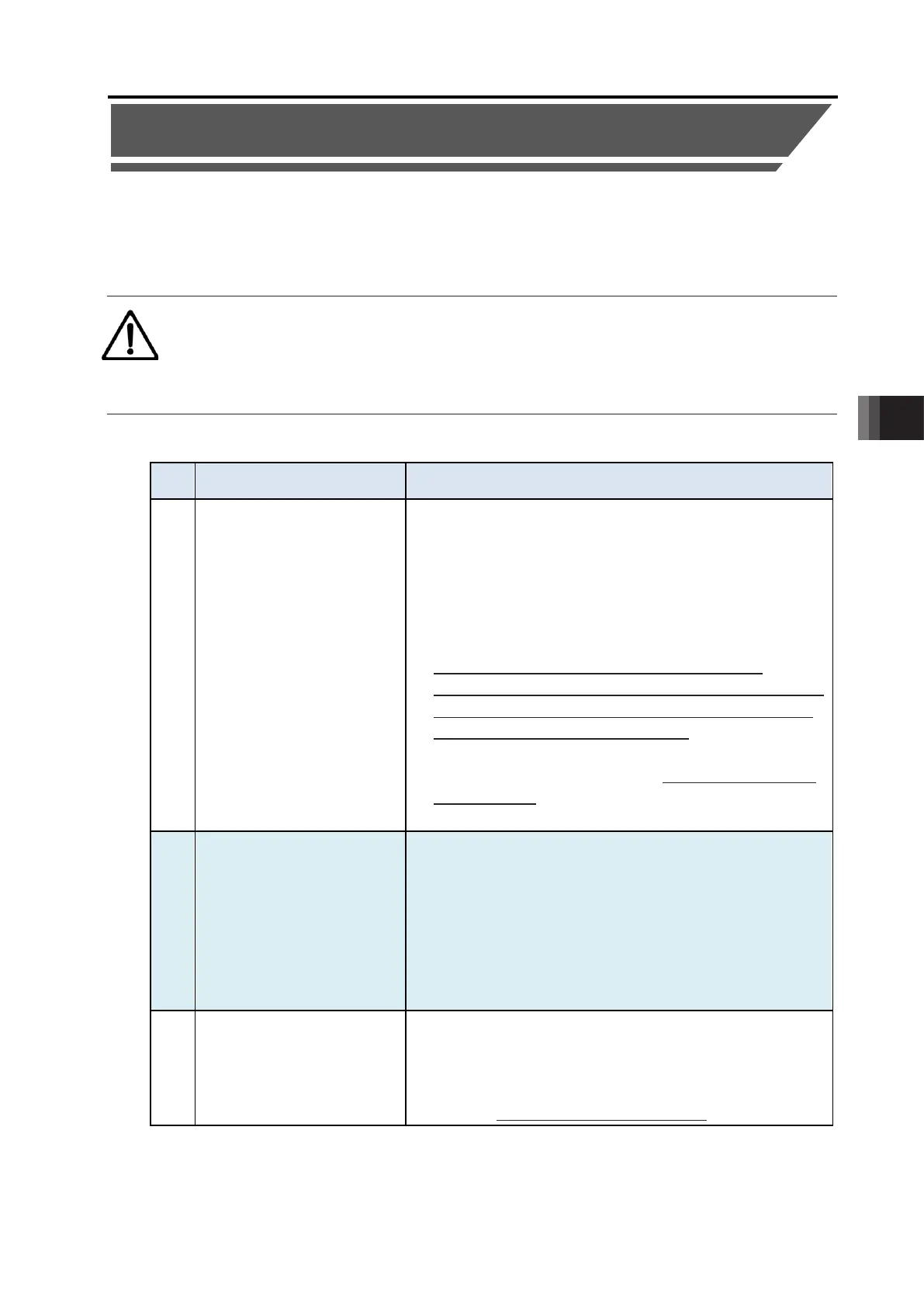

6.2 Servo Adjustment

ME0342-4B 6-58

6.2 Servo Adjustment

At shipment from factory, parameters are set so that operation at rated load (maximum) is within

the payload capacity of the actuator and with stable operating characteristics.

However, at the actual usage sites, it may be necessary to perform servo adjustment.

This section explains the basic servo adjustment method.

Caution

● It is dangerous to make excessive settings suddenly. Damage to the equipment or the

actuator or injury may occur, so proceed with caution.

● Also, make sure to keep a record as you work so that it can be restored at any time.

● If you face problems which cannot be resolved, contact IAI.

Adjustment method

No. Problems Adjustment method

1 • Positioning takes time

• Positioning accuracy is

insufficient

• Tact time needs to be

shorter

• Set Parameter No. 55 "Position Command Primary Filter

Time Constant" to "0" if it is set.

• Increase Parameter No. 7 "Servo Gain Number". The

increased set value improves tracking of position

command. As a guideline for setting, set 3 to 10, at most

15 or less. If it is too high, overshoot may occur, which

will cause sound and vibration.

• When increasing Parameter No. 7 "Servo Gain

Number", Parameter No. 31 "Velocity Loop Proportional

Gain" should also be increased accordingly in order to

ensure stability of the control system.

• When increasing Parameter No. 31 "Velocity Loop

Proportional Gain", make sure to set it to about 20% of

the initial value. Adjust Parameter No. 7 "Servo Gain

2 Vibration occurs during

acceleration/deceleration

• This may be caused by excessive

"Acceleration/Deceleration Setting," or inadequate

rigidity of the device on which the actuator is mounted.

• Lower "Acceleration/Deceleration Setting".

• Lower Parameter No. 7 "Servo Gain Number".

However, if Parameter No. 7 "Servo Gain Number" is too

low, convergence will take longer.

• Consider reinforcing the device.

• Speed irregularity occurs

during travel

• Speed accuracy is

insufficient

• Increase Parameter No. 31 "Velocity Loop Proportional

Gain". The increased set value improves tracking of

speed command. If it is too large, mechanical system

vibration may occur. As a setting guideline, try to

increase the initial values by about 20% respectively.

Loading...

Loading...