Important

In the event of mounting the fitting P on the crankcase

E (tightening torque of 15 Nm with Loctite 2701 on the

thread).

NOTE: To assemble the oil cartridge refer to operations 5 and 6

of Par. 6.10.2 .

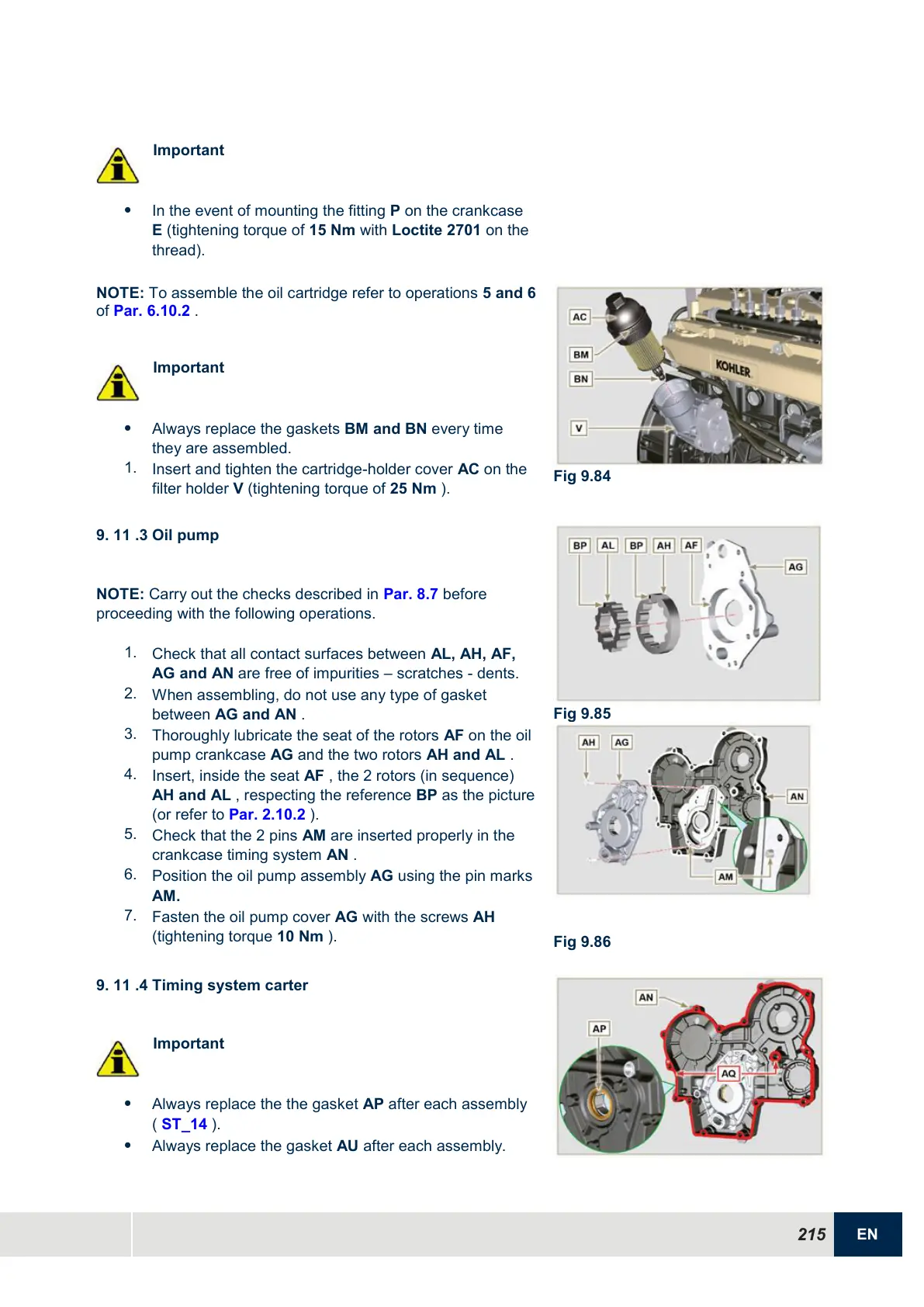

Important

Always replace the gaskets BM and BN every time

they are assembled.

1.

Insert and tighten the cartridge-holder cover AC on the

filter holder V (tightening torque of 25 Nm ).

9.

11 .3 Oil pump

NOTE:

Carry out the checks described in

Par. 8.7

before

proceeding with the following operations.

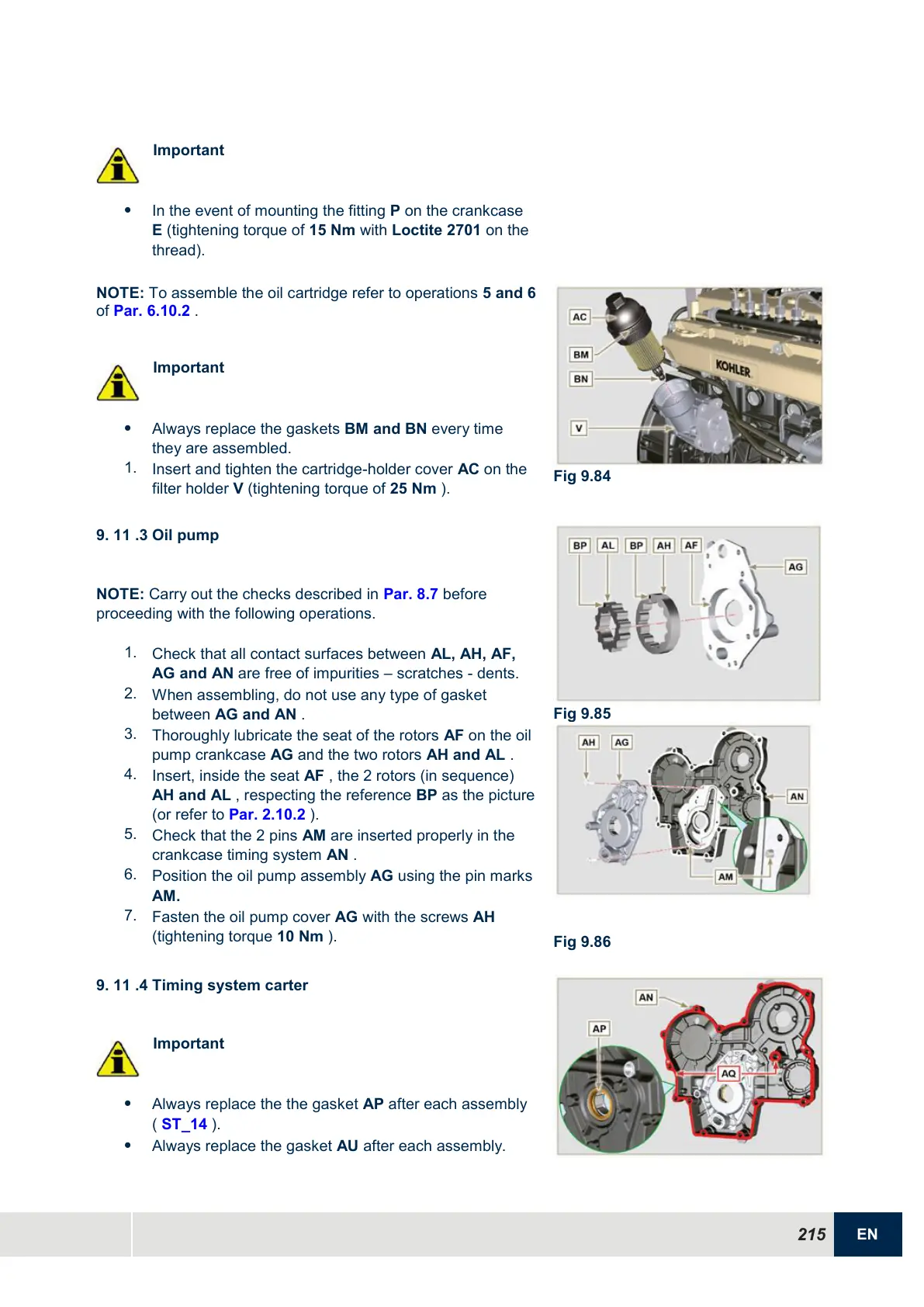

1.

Check that all contact surfaces between AL, AH, AF,

AG and AN are free of impurities – scratches - dents.

2.

When assembling, do not use any type of gasket

between AG and AN .

3.

Thoroughly lubricate the seat of the rotors AF on the oil

pump crankcase AG and the two rotors AH and AL .

4.

Insert, inside the seat AF , the 2 rotors (in sequence)

AH and AL , respecting the reference BP as the picture

(or refer to

Par. 2.10.2 ).

5.

Check that the 2 pins AM are inserted properly in the

crankcase timing system AN .

6.

Position the oil pump assembly AG using the pin marks

AM.

7.

Fasten the oil pump cover AG with the screws AH

(tightening torque 10 Nm ).

9.

11 .4 Timing system carter

Important

Always replace the the gasket AP after each assembly

( ST_14 ).

Always replace the gasket AU after each assembly.

Loading...

Loading...