Do NOT execute the forced regenerations if not required by the ECU (due to a Level 0 - 2 particulate

accumulation).

The minimum engine speed increases during the forced regeneration phases.

Repeated forced regenerations cause significant engine oil contamination by the fuel.

The oil level check must be executed after every forced regeneration.

If the regeneration inhibition function is misused, the particulate accumulation level will increase

within a short time.

The engine oil filter and oil must be changed after a Service Regeneration is completed via KOHLER

software

(Level 5 Particulate accumulation).

Fuel contamination allowed in the engine oil is 3% MAX.

Any engine load must be eliminated during forced regeneration so as to prevent damaging the ATS

*2 system.

Do not switch the engine off during level 3, 4 and 5 regeneration so as to prevent damaging the ATS

system.

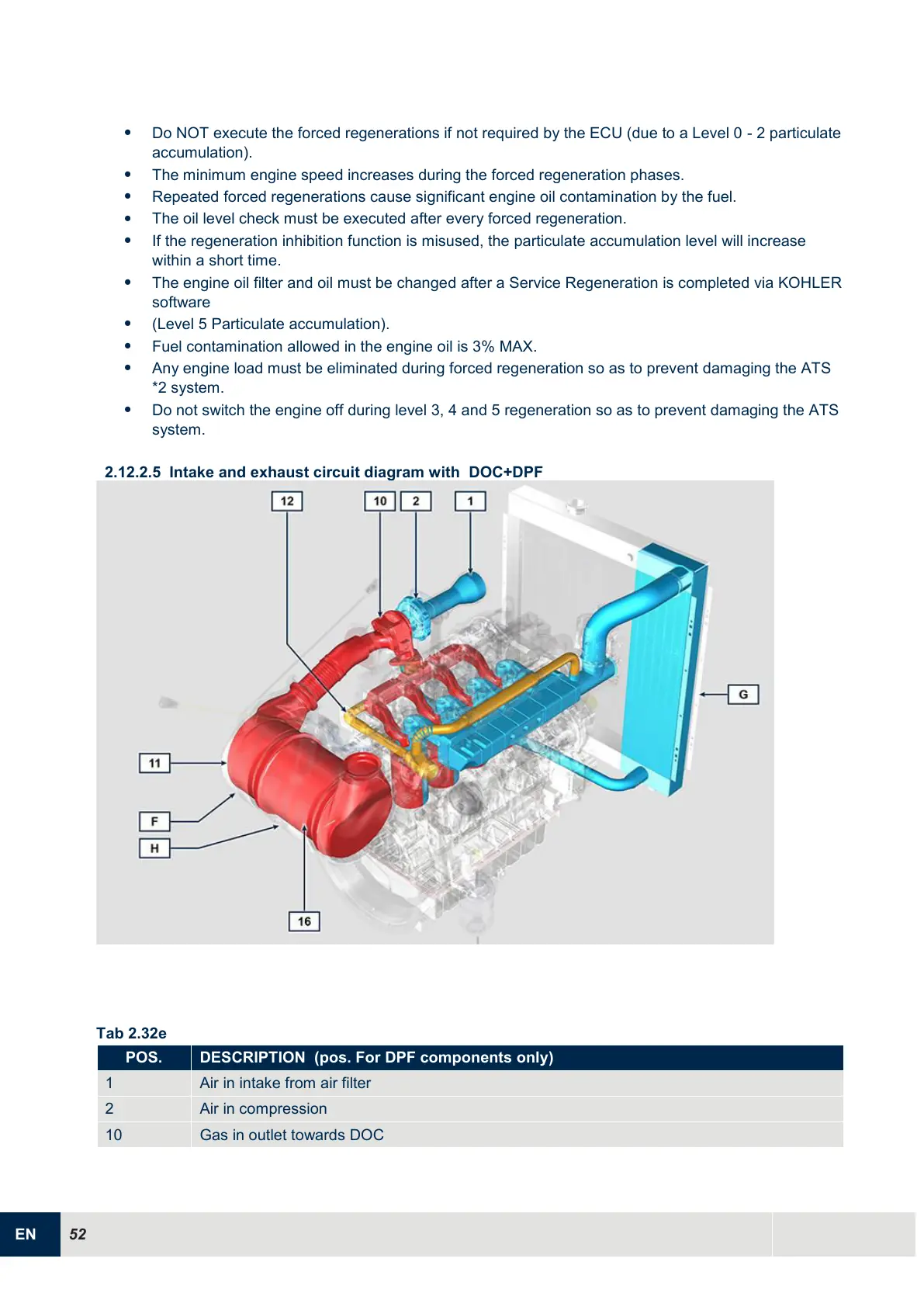

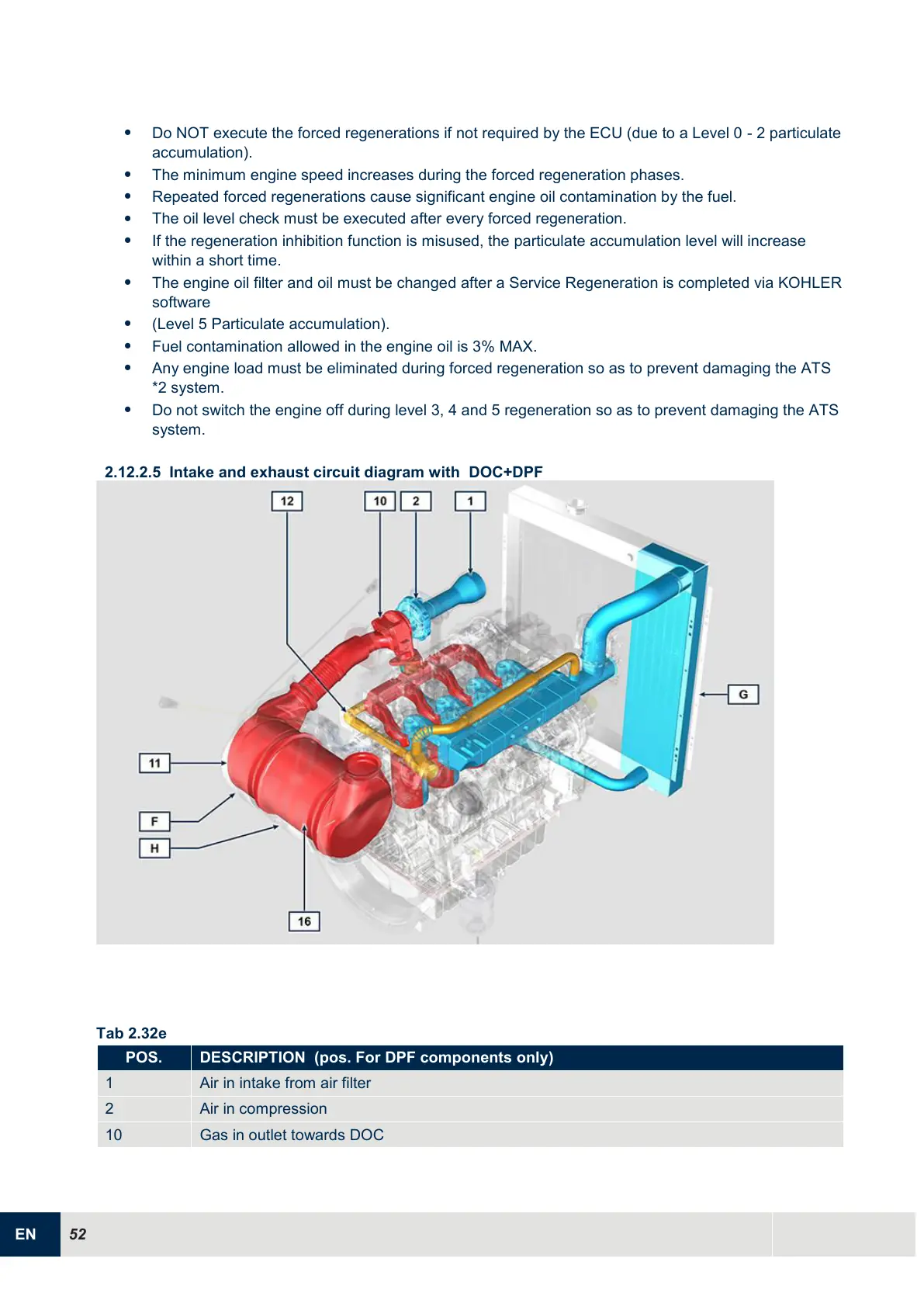

Loading...

Loading...