OPERATION MACHINE OPERATIONS AND CONTROLS

3-199

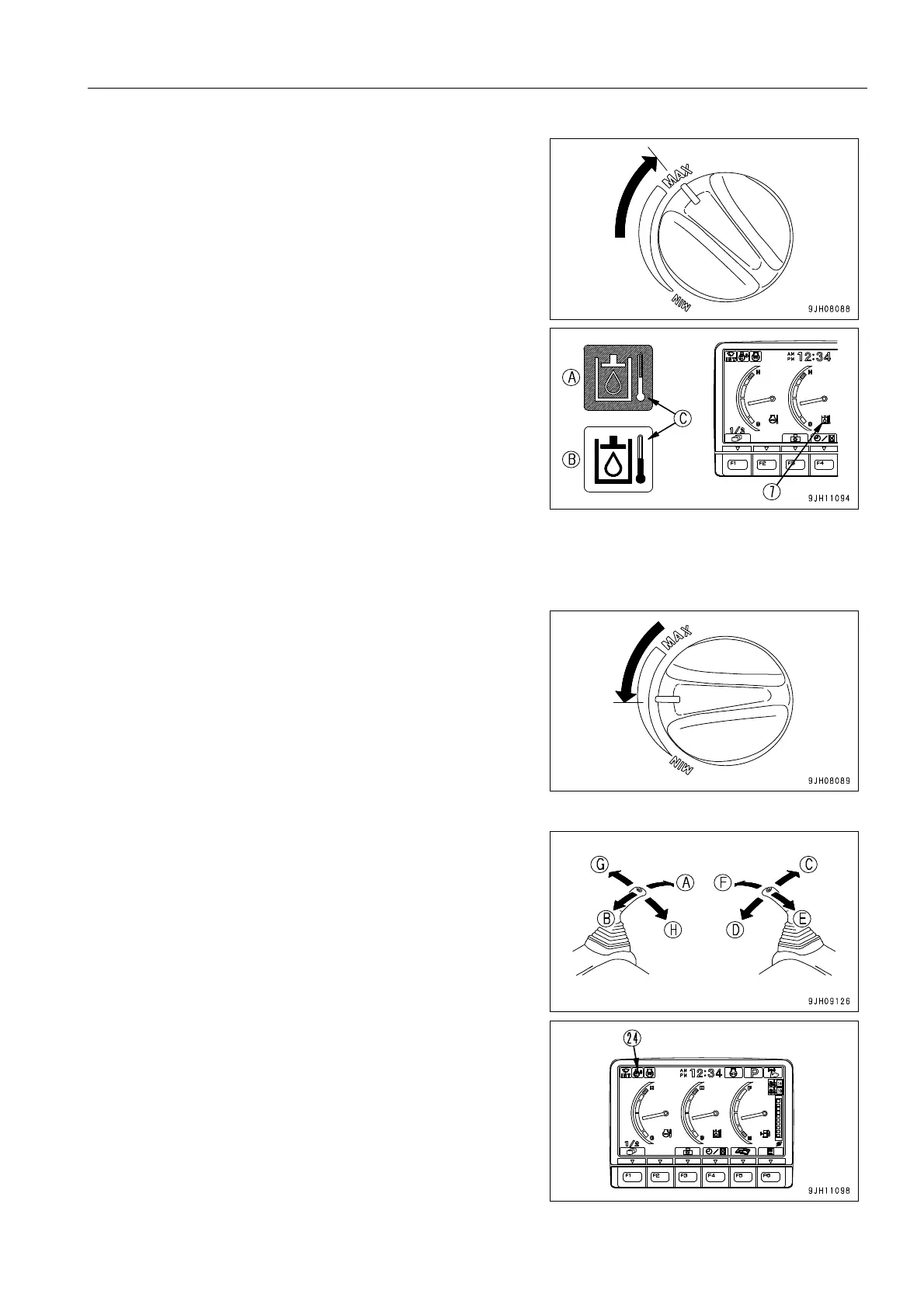

15. Turn fuel control dial (4) to the full speed (MAX) position,

repeat Steps 6 to 9 for 3 to 5 minutes, then check again

that the hydraulic oil temperature monitor is displaying the

correct temperature.

If it is not displaying the correct temperature, repeat Steps

6 to 9 for 3 to 5 minutes until hydraulic oil temperature

monitor (7) displays the correct temperature.

(A) Display when temperature is correct: Monitor back-

ground (C) is blue

(B) Display when temperature is low: Monitor background

(C) is white

For both normal temperatures and cold temperatures, carry out the following operation.

16. Check that fuel control dial (4) is at a point midway

between low idling (MIN) and full speed (MAX).

If it is not at the midway position, set it to the midway posi-

tion and run the engine at a mid-range speed before oper-

ating.

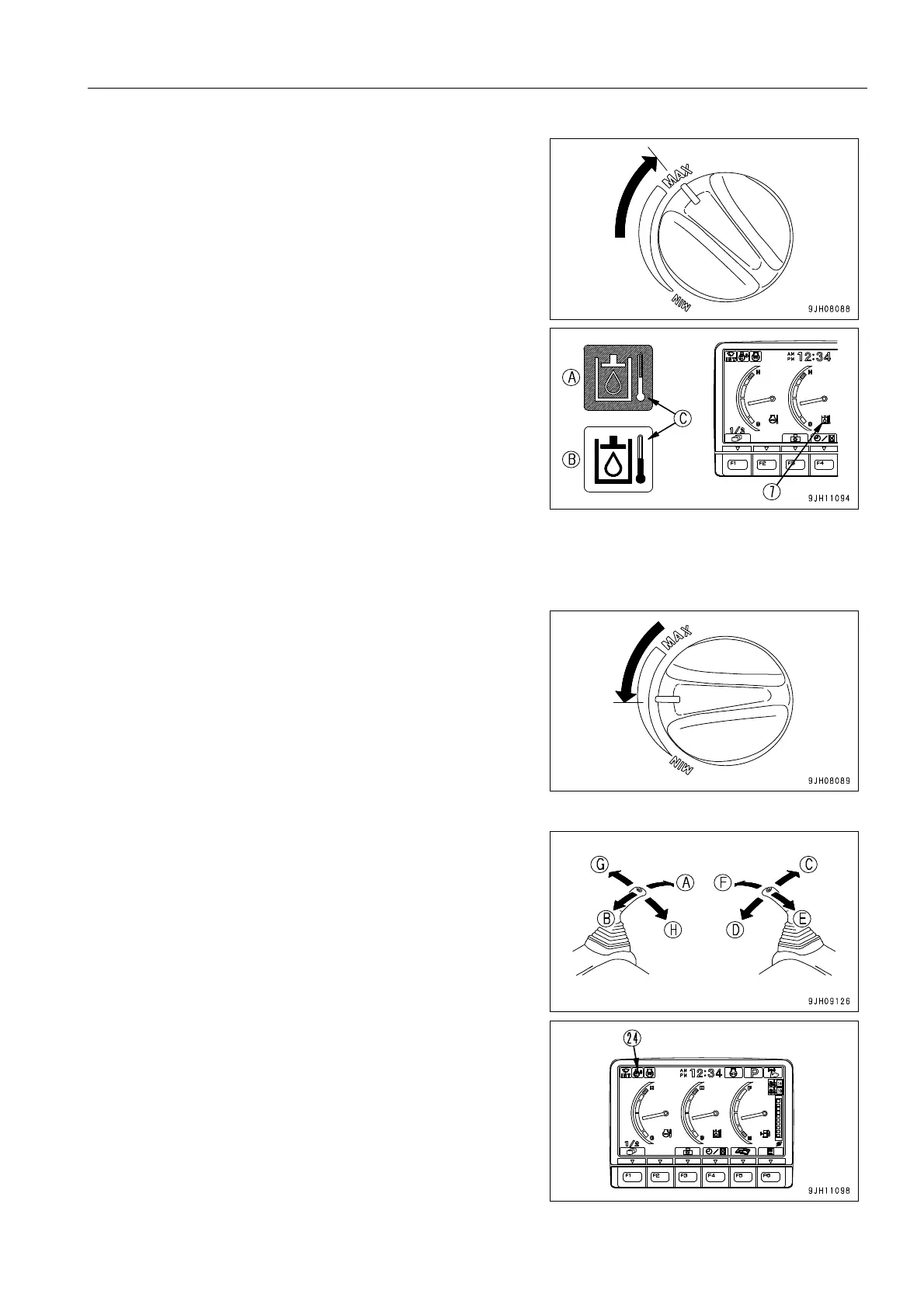

17. Before starting operations, repeat the following operations

slowly 3 to 5 times to circulate warm oil through the control

circuits.

q Boom control : RAISE (E) ←→ LOWER (F)

q Arm control : IN (B) ←→ OUT (A)

q Bucket control: CURL (D) ←→ DUMP (C)

Before carrying out swing operations, cancel swing lock

switch (2) and check that swing lock monitor (24) has gone

out.

q Swing control : Left (G) ←→ Right (H)

Loading...

Loading...