MAINTENANCE PROCEDURE MAINTENANCE

4-42

CHECK AND MAINTENANCE AIR CONDITIONER 4

Check Level of Refrigerant (gas)

If the refrigerant used in the air conditioner gets into your eyes or on your hands, it may cause loss of

sight or frostbite. Do not touch the refrigerant. Never loosen any part of the refrigerant circuit.

Do not bring any flame close to any point where the refrigerant gas is leaking.

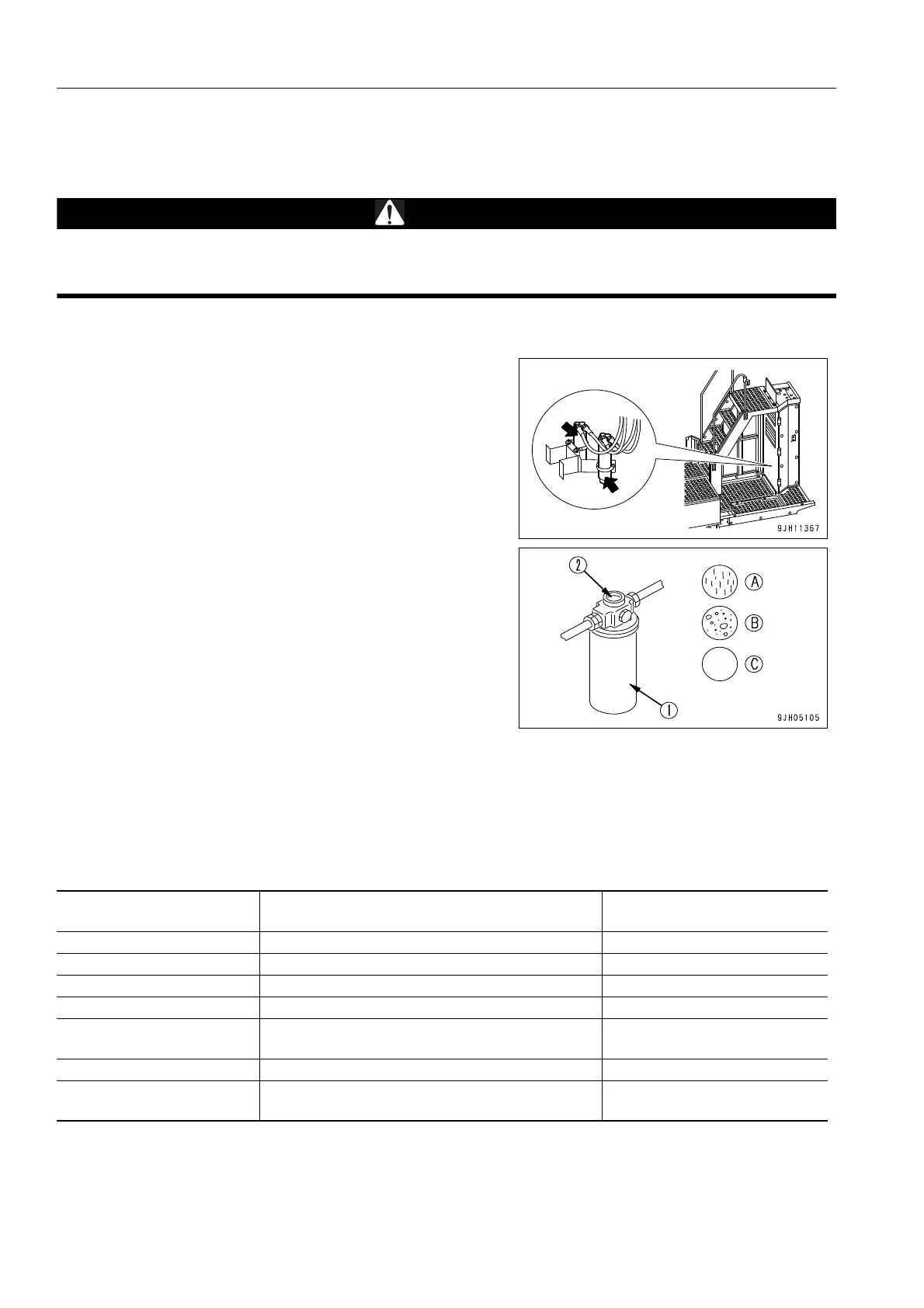

If there is a lack of refrigerant (gas), the cooling performance

will be poor. When operating the air conditioner at high speed

with the engine at full throttle, use the receiver sight glass

(inspection window) to check the condition of the refrigerant

gas (R134a) flowing in the refrigerant circuit.

(A) No bubbles in refrigerant flow: Suitable

(B) Some bubbles in flow (bubbles pass continuously):

Lack of refrigerant

(C) Colorless, transparent: No refrigerant

When bubbles appear, there is lack of refrigerant gas, so have

your service shop add refrigerant immediately. If the air condi-

tioner is run when there is lack of refrigerant gas, it will cause

damage to the compressor.

Total volume of refrigerant: 0.95 kg (2.095 lb)/each unit [total

for 2 units: 1.9 kg (4.19 lb)]

Inspection During Off Season

During the off-season, run the air conditioner once a month for 3-5 minutes at low idling to maintain the oil film at

all parts of the compressor.

Inspection and Maintenance Items

Check, maintenance items Content of check, maintenance

Guideline for maintenance inter-

val

Refrigerant (gas) Charge amount Twice a year (spring, autumn)

Air conditioner condenser Clogged fins Every 500 hours

Compressor Operating condition Every 4000 hours

V-belt Damage, tension Every 250 hours

Blower motor, fan

Operating condition

(does it make abnormal noise?)

When required

Control mechanism Operating condition (does it function normally?) When required

Piping mounts

Mounting condition, looseness at tightening or

connecting portions, leakage of gas, damage

When required

Loading...

Loading...