OPERATION MACHINE OPERATIONS AND CONTROLS

3-227

ESCAPE FROM MUD 3

When operating, be careful not to get stuck in mud. If the machine gets stuck in mud, do as follows to get the

machine out.

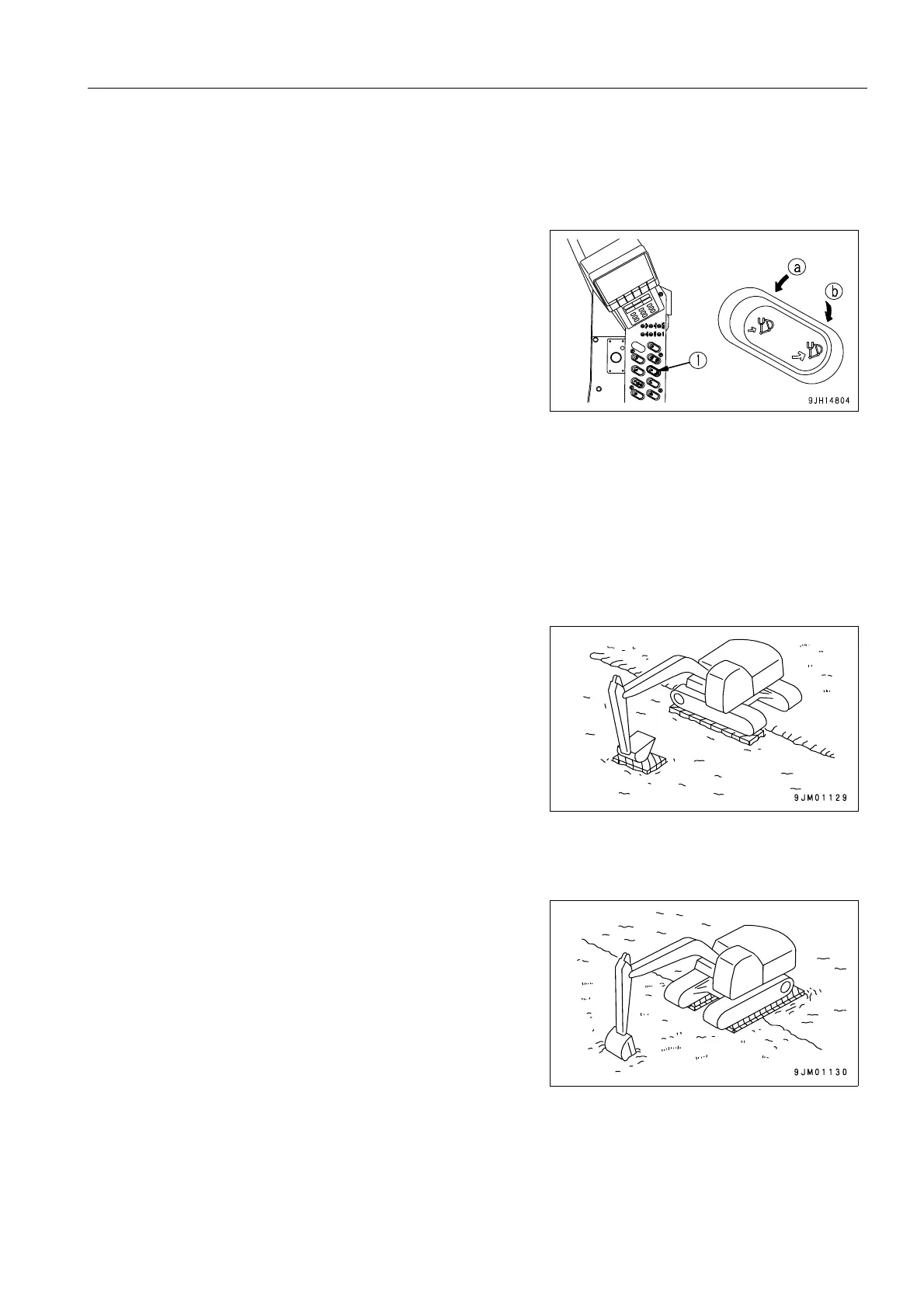

q If the machine push-up switch (1) is set to position (b), the

pushing force of the boom is increased to make it easier for

the machine to escape from mud.

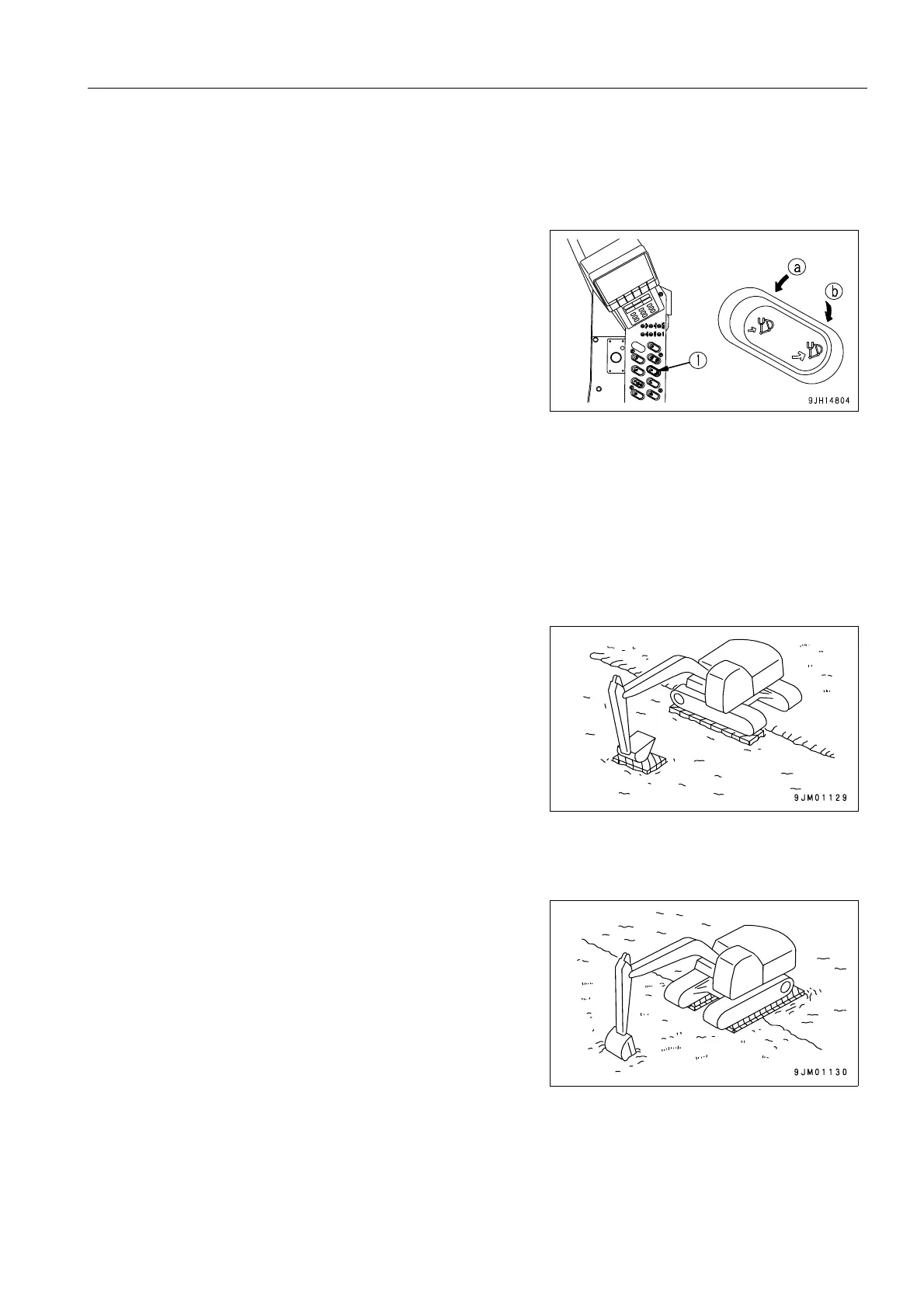

Track on One Side Stuck 3

When using the boom or arm to raise the machine, always have the bottom of the bucket in contact with

the ground. (Never push with the teeth). The angle between the boom and arm should be 90° to 110°.

The same applies when using the inverted bucket.

When only one side is stuck in mud, use the bucket to raise the

track, then lay boards or logs and drive the machine out.

Tracks on Both Sides Stuck 3

When the tracks on both sides are stuck in mud and they slip,

making it impossible for the machine to move, lay boards or

logs as explained above, and dig the bucket into the ground in

front. Then pull in the arm as in normal digging operations and

put the travel levers in the FORWARD position to pull the

machine out.

Loading...

Loading...