MAINTENANCE PROCEDURE MAINTENANCE

4-30

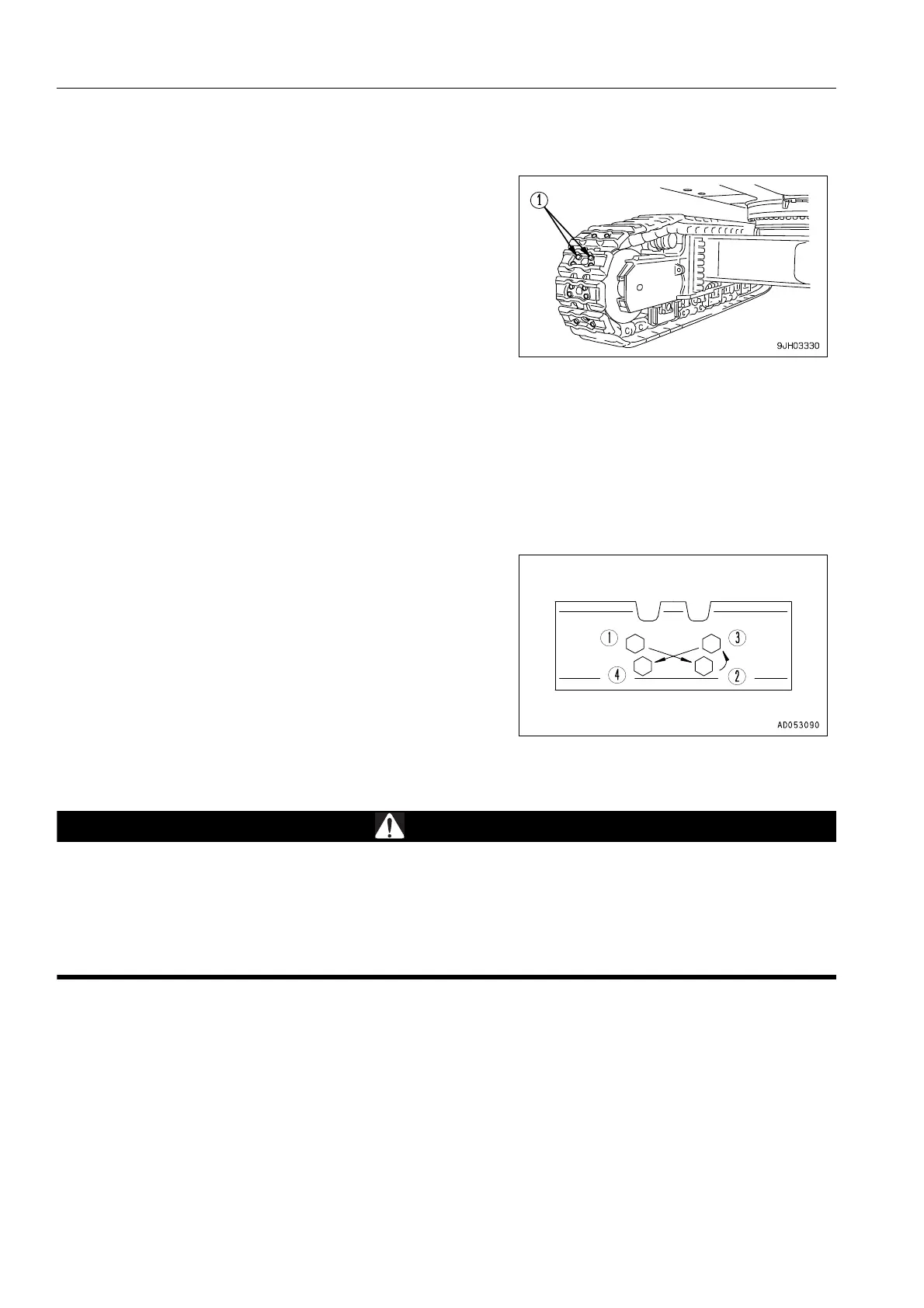

CHECK AND TIGHTEN TRACK SHOE BOLTS 4

If the machine is used with track shoe bolts (1) loose, they will

break, so tighten any loose bolts immediately.

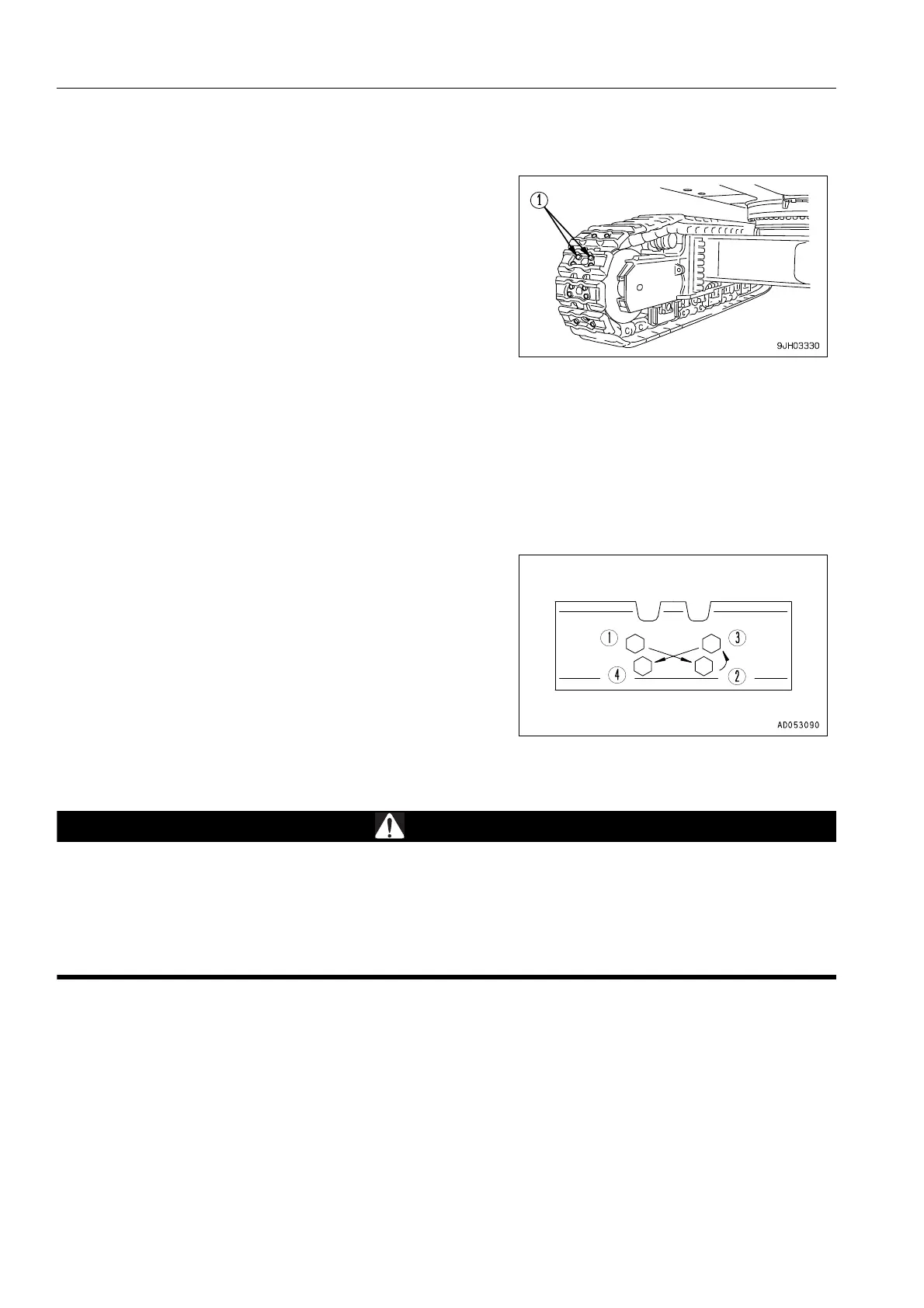

Tightening

1. Tighten first to a tightening torque of 686 ± 69 Nm (70 ± 7 kgm), then check that the nut and shoe are in tight

contact with the link mating surface.

2. After checking, further tighten to the tightening torque of 150° ± 10°.

Order for Tightening

Tighten the bolts in the order shown in the diagram on the right.

After tightening, check that the nut and shoe are in close con-

tact with the link mating surface.

CHECK AND ADJUST TRACK TENSION 4

q For details of the method of starting the engine and operating the work equipment, see “BEFORE

STARTING ENGINE (3-158)“, “STARTING ENGINE (3-189)“, “AFTER STARTING ENGINE (3-192)“, and

“WORK EQUIPMENT CONTROLS AND OPERATIONS (3-217)“.

q Before carrying out this operation, always bleed the air from the circuit. For details of the procedure

for bleeding air from the hydraulic circuit, see “BLEEDING AIR FROM IDLER CUSHION CIRCUIT (4-

52)“.

The wear of the pins and bushings on the undercarriage will vary with the working conditions and type of soil, so

inspect the track tension frequently in order to maintain the standard tension.

Stop the machine on firm, horizontal ground when carrying out the inspection and maintenance.

Loading...

Loading...