OPERATION TROUBLES AND ACTIONS

3-241

TOWING THE MACHINE 3

Serious injury or death could result if a disabled machine

is towed incorrectly or if there is a mistake in the selection

or inspection of the wire rope.

Always check that the wire rope used for towing has ample

strength for the weight of the machine being towed.

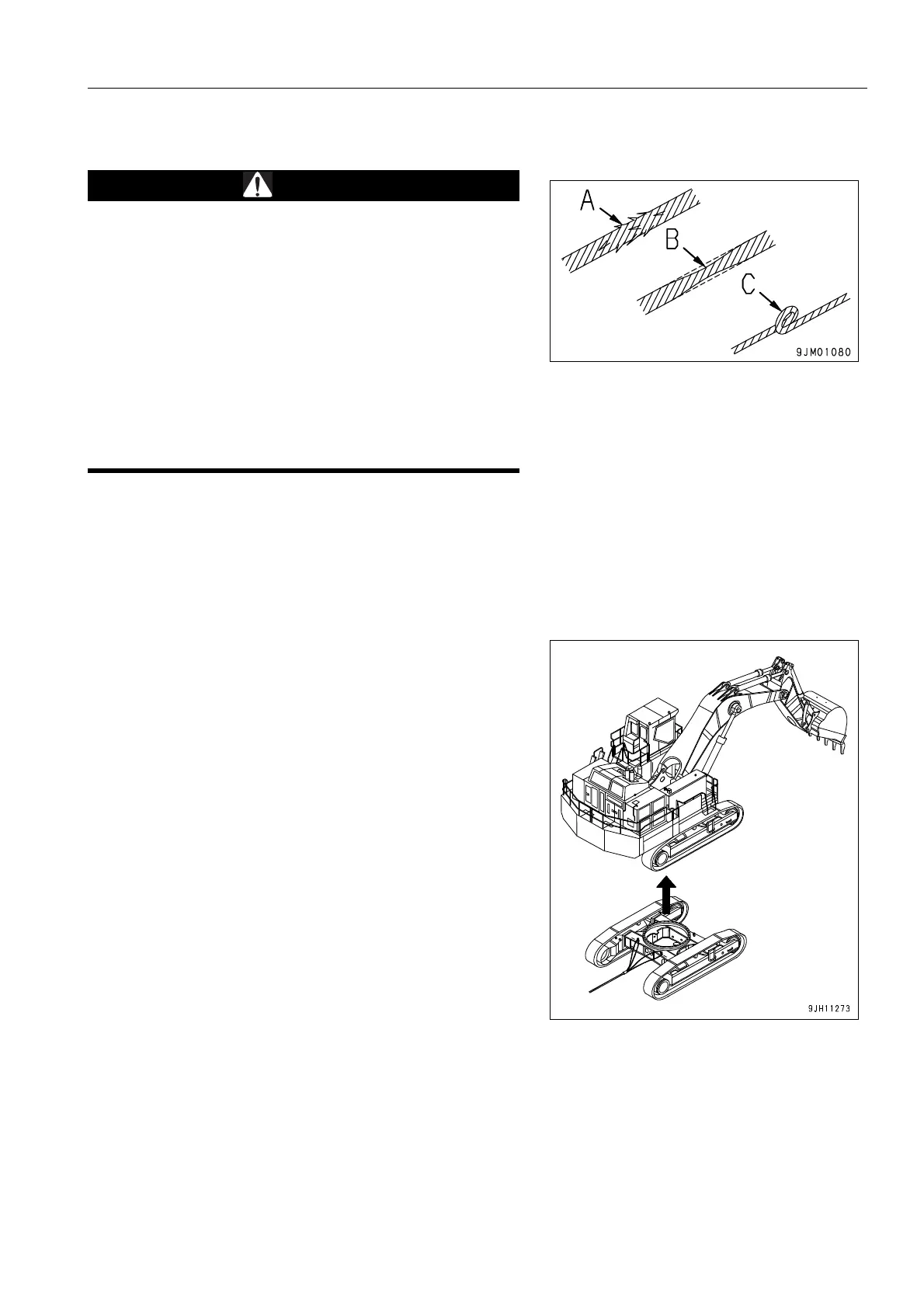

Never use a wire rope which has cut strands (A), reduced

diameter (B), or kinks (C). There is danger that the rope

may break during the towing operation.

Always wear leather gloves when handling wire rope.

Never tow a machine on a slope.

During the towing operation, never stand between the tow-

ing machine and the machine being towed.

Operate the machine slowly and be careful not to apply

any sudden load to the wire rope.

The maximum towing capacity for this machine is 1,079 kN (110,027 kg).

Always carry out towing operations within the maximum towing capacity.

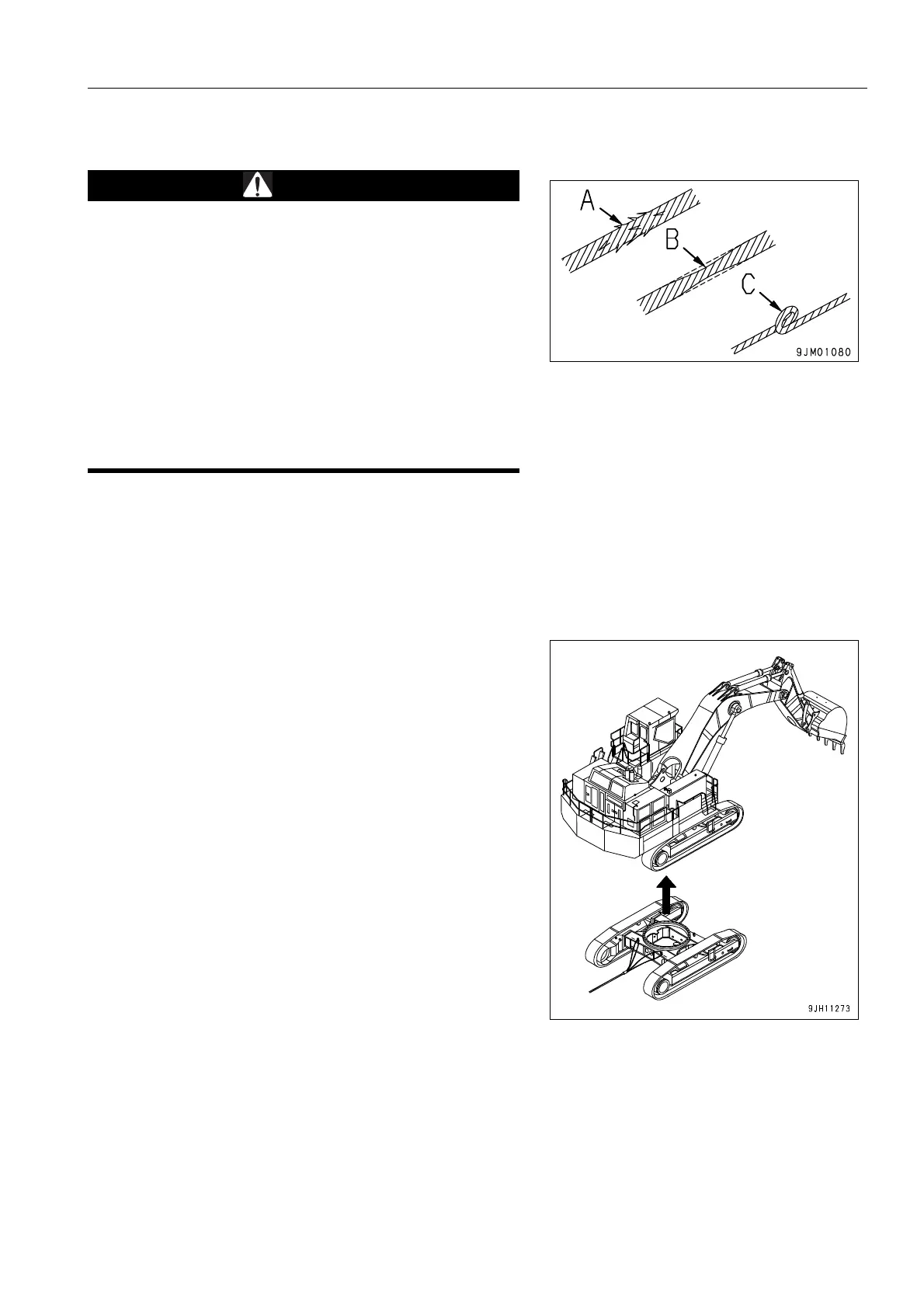

q If the machine sinks in mud and cannot get out under its

own power, or if the drawbar pull of the excavator is being

used to tow a heavy object, use a wire rope as shown in

the diagram on the right.

q Place pieces of wood between wire ropes and body to pre-

vent damage to ropes and body.

q When towing a machine, travel at a speed of less than 1

km/h for a distance of only a few meters to a place that is

suitable for carrying out repairs.

This is for use only in emergencies.

SEVERE JOB CONDITION 3

q When carrying out digging operations in water, if the work equipment mounting pin goes into the water, carry

out greasing every time the operation is carried out.

q For heavy-duty operations and deep digging, carry out greasing of the work equipment mounting pins every

time before operation.

After greasing, operate the boom, arm and bucket several times, then grease again.

Loading...

Loading...