BA 35101/02/ 03 EN – Edition 1.0 * 35101_02_03b330.fm 3-61

Operation

Loading and tying down the machine

☞ Load as follows:

• Secure the transport vehicle with chocks to prevent it from rolling

• Place the access ramps at the smallest possible angle

• Do not exceed an angle of 20°

• Use access ramps with an antiskid surface only

• Make sure the loading area is clear and that access to it is not obstructed

• Make sure the access ramps and the wheels of the machine are free of oil, grease

and ice

• Check the engine oil level – see chapter 5 “Checking the engine oil level” on page 5-5

• Start the engine of the machine

• Raise the loader unit enough so that it will not touch the access ramps

• Carefully drive the machine onto the middle of the transport vehicle

• Set the drive to neutral –seeChanging direction (forwards/reverse) on page 3-38

• Lower the loader unit (bucket) to the loading area of the transport vehicle

• Stop the engine

• Apply the parking brake –seeApplying the parking brake on page 3-36

• Remove the ignition key

• Do not allow anyone to stay in the cab, and close the doors and the engine cover

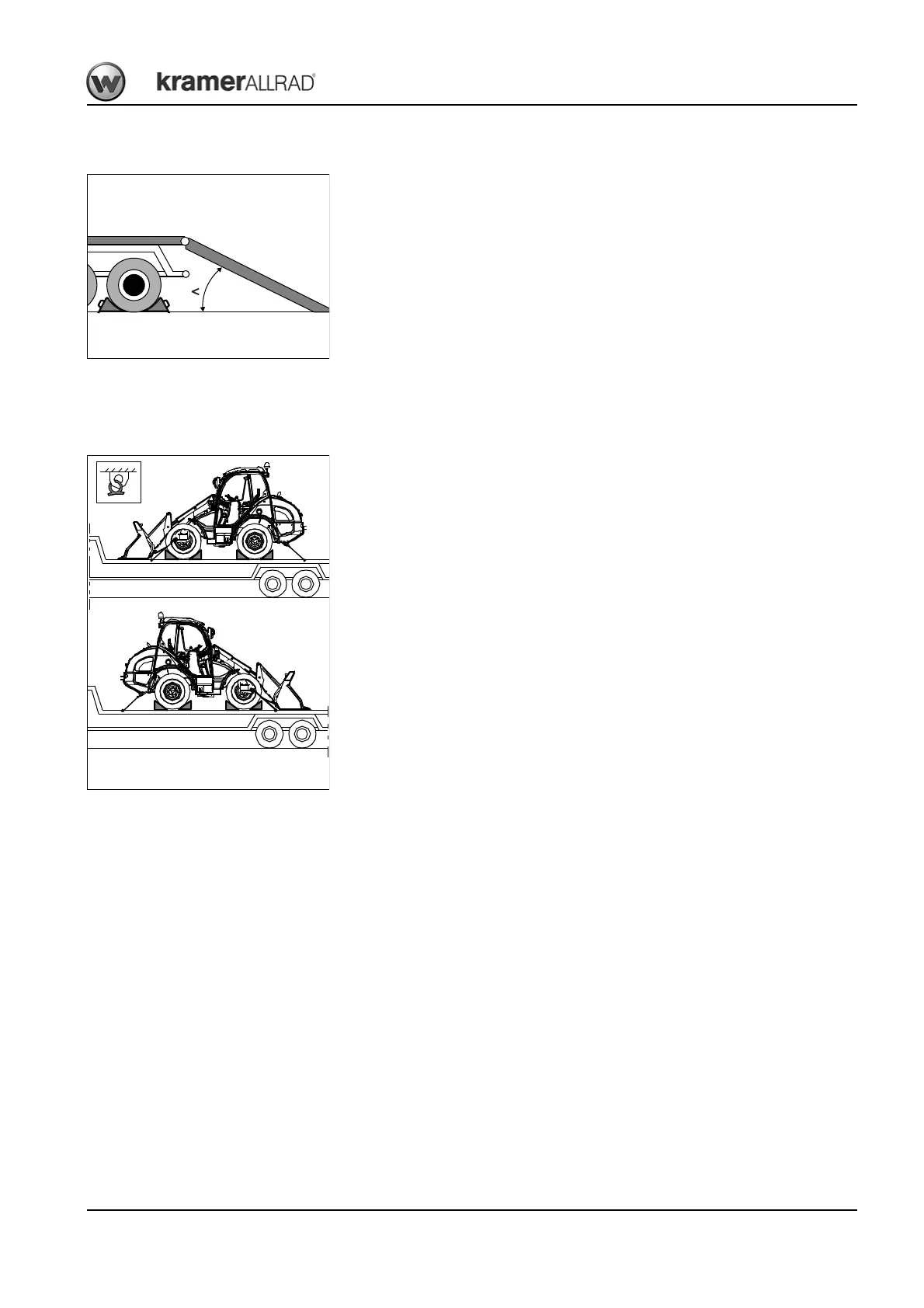

☞ Tie down the machine as follows:

• Firmly tie down the machine at the eye hooks – see chapter 1 “Machine outside view”

on page 1-2 – with sufficiently dimensioned belts or chains onto the platform. If

possible, secure the wheels with additional chocks at the front, rear and at the sides

• Before transporting the machine through heavy rain: close the outlet of the exhaust

silencer with a simple cap or suitable adhesive tape

• Make sure the driver of the transport vehicle knows the overall height, width and

weight of his vehicle (including the load) before moving off, and the legal transport

regulations of the country or countries in which transport will take place!

Fig. 99: Tying down the loader

Loading...

Loading...