5-2 BA 35101/02/03 EN – Edition 1.0 * 35101_02_03b510.fm

Maintenance

5.2 Fuel system

Safety instructions for refuelling

• Extreme caution is essential when handling fuel – high risk of fire!

• Never carry out work on the fuel system in the vicinity of naked flames or sparks!

• Do not smoke when working on the fuel system or when refuelling!

• Before refuelling, stop the engine and remove the ignition key!

• Do not refuel in closed rooms!

Use a suitable container to collect the fuel as it drains and dispose of it in an

environmentally friendly manner! Keep the machine clean to reduce the risk of

fire and wipe away fuel spills immediately!

Diesel fuel specification

Use only the diesel fuels listed in the table below!

☞ If other fuels are used, warranty rights shall not apply in case of diesel

engine damage (guarantee)!

☞ Do not use diesel fuel with additives

Stationary fuel pumps

General instructions

Only refuel from stationary fuel pumps. Fuel from barrels or cans is usually contaminated.

Even the smallest particles of dirt can cause increased engine wear

• Malfunctions in the fuel system and

• Reduced effectiveness of the fuel filters

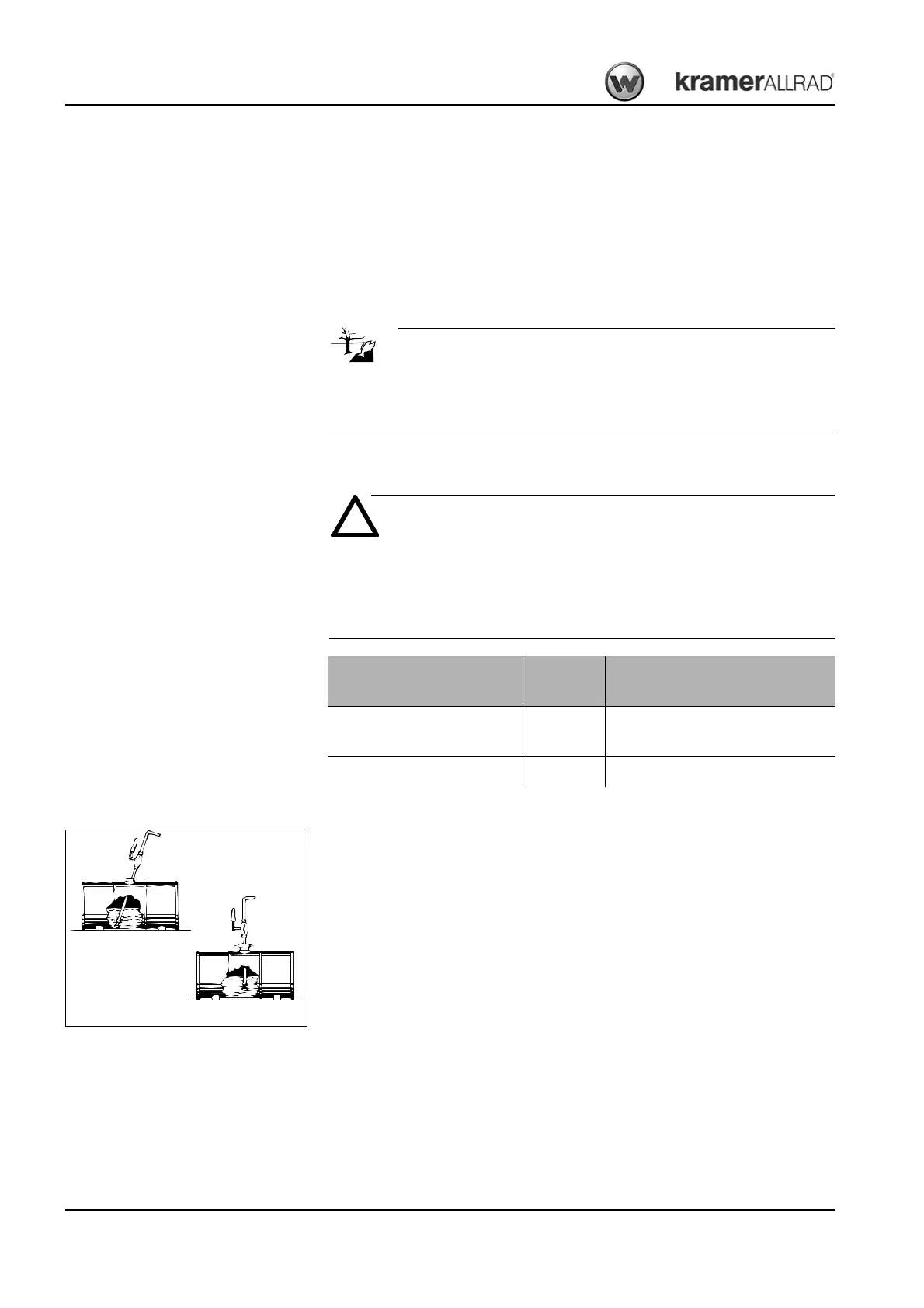

Refuelling from barrels

If refuelling from barrels cannot be avoided, note the following points:

• Barrels must neither be rolled nor tilted before refuelling

• Protect the suction pipe opening of the barrel pump with a fine-mesh strainer

• Immerse it down to a max. 15 cm above the floor of the barrel

• Only fill the tank using refuelling aids (funnels or filler pipes) with integral microfilter

• Keep all refuelling containers clean at all times

Specification

Cetane

number

Use (°C)

DIN 51628/DIN EN 590 (EU),

ASTM D975-94 (USA)

Min. 49 Up to -44 °C outside temperature

EN 14214 (biodiesel)

Min. 51

Up to -20 °C outside temperature

Wrong

Right

✓

✗

Fig. 154: Refuelling from a barrel

Loading...

Loading...