BA 35101/02/ 03 EN – Edition 1.0 * 35101_02_03b520.fm 5-43

Maintenance

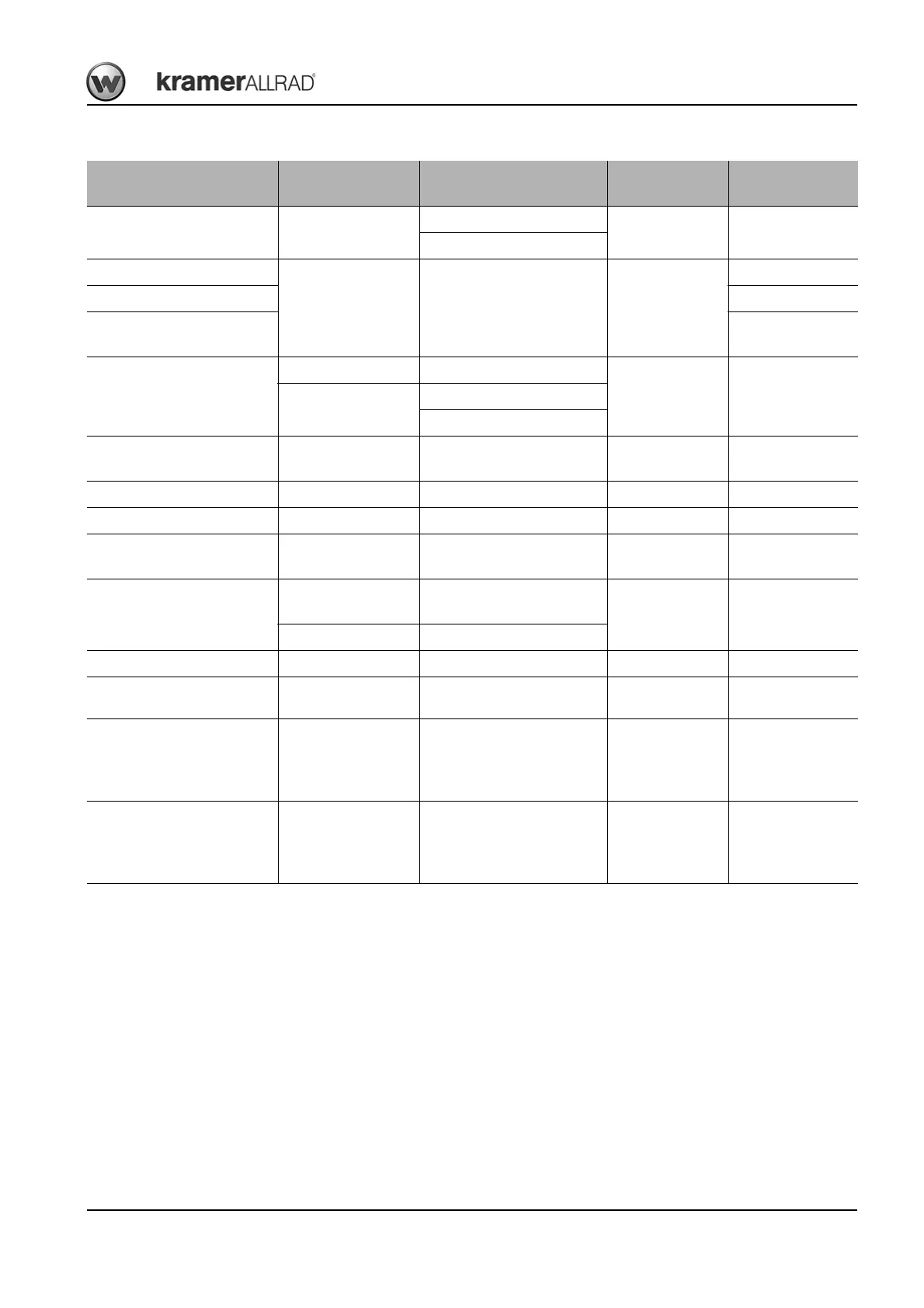

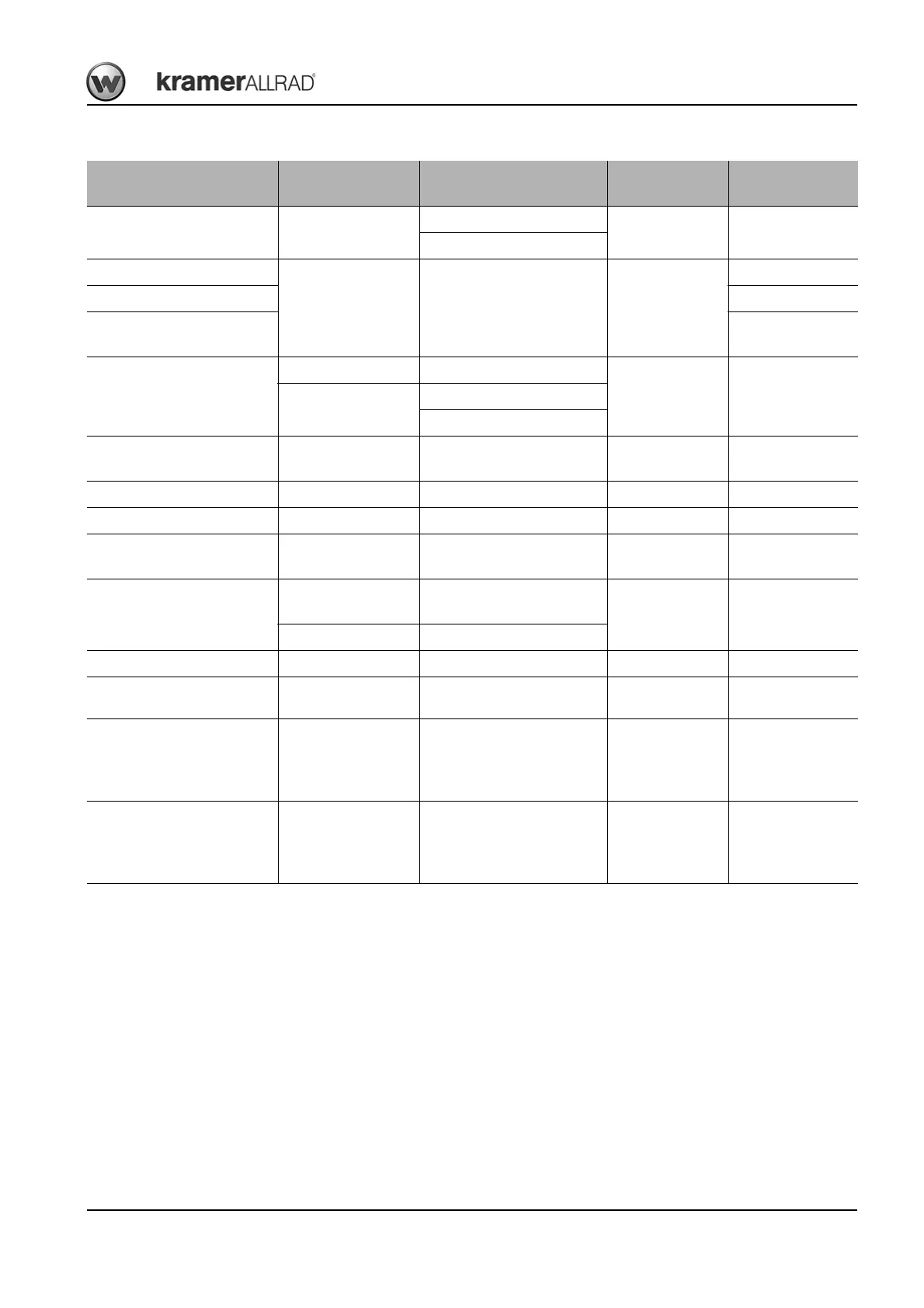

5.21 Fluids and lubricants

Component/ application Engine/machine fluid SAE grade Specification

Season/tempera-

ture

Capacities

1

1. The capacities indicated are approximative values; t he oil level check alone is relevant for the correct oil level

Diesel engine

2

Engine oil with oil filter

2. MIL-L-2104C; API CD/CE/CH4; CCMC-D4

HD-C 10W-40; EO1040B

3

3. Abbreviation for lubricants (Haupt verband der Deutschen Bauindustrie e. V. – German construction engineering association)

Year-round

About 10.5 l

(2.77 gal)

HD-C 15W-40; EO1540B

3

Gearbox

Gearbox oil

4

4. MIL-L-2105B; API-GL5

85 W 90 API GL5 or

SAE 90 LS (hypoid gear oil)

Year-round

0.8 l (0.21 gal)

Front and rear axle differentials 4.0 l (1.05 gal)

Planetary drives – left and right,

front and rear axles

0.9 l (0.23 gal) each

Hydraulic oil tank

Hydraulic oil

5

5. DIN 51 524

HVLPD 46 (HYD0530)

Year-round

About 64 l

6, 7

(16.90 gal)

6. Complete refill of wheel loader about 103 l

7. With oil change of high speed gearbox 40 kph (option) + 10 l

Biodegradable oil

AVILUB Syntofluid 46

PANOLIN HLP Synth 46

Grease nipples, loader unit/axles Multipurpose grease

Lithium-saponified brand-name

grease MPG-A

3

Year-round As required

Battery terminals Acid-proof grease SP-B

3

Year-round As required

Aggressive media (option) Anticorrosion protection Anticorit BW 366

8

8. TI 8030-015/K 19/MIL-C-16 173 C-Grade 4

Year-round As required

Mounting

9

of pins, shafts

9. Important! Pins (hard-chromium plated or coated with Molykote 3400A) are inserted in dry state. Lubricate via grease nipples once assembly is over

Special grease

Optimoly paste “TA”

10

White-Paste

10. 250 gr tube, order no.: 1000030311

Year-round As required

Fuel system, fuel tank

11

11. With additional tank about 60 l (option)

Diesel fuel

12,13

12. In order to avoid engine damage, do not add additives to the diesel fuel!

13. If fuels are used that do not comply with the standards in the table, warranty rights shall not apply in case of diesel engine damage

DIN 51628/DIN EN 590 (EU)

ASTM D975-94 (USA)

Year-round -40 °C

(-40 °F)

About 85 l

(22.45 gal)

Biodiesel

12, 13

DIN EN 14214

Brake system Brake fluid

14

14. Standard: B 71 2710

Agip LHM Super/Shell LHM Year-round –

Air conditioning (option)

15

15. Maintenance work must be carried out by trained staff only

Refrigerant

16

16. Bear in mind the safety data sheet during maintenance work

R 134a Year-round

About 850 g

(1.87 lbs.)

Engine cooling Antifreeze

17, 18, 19

17. SeeCoolant compound table on page 6-13

18. See manufacturer's indications on the packaging and bear in mind the antifreeze compound table

19. Replace the coolant every 2 years!

MS Frostschutz

HAVOLINE XLC

Year-round

-31 °C (-23.8 °F)

Water

4.4 l (1.17 gal)

Antifreeze

5.4 l (1.42 gal)

Washer system Cleaning agent

18

Water + antifreeze

Year-round

-20 °C (-4 °F)

Water

(67 %) 1.3 l (0.34 gal)

Antifreeze

(33 %) 0.7 l (0.18 gal)

Maintenance

Loading...

Loading...