Mini-Crawler Crane M A E D A Section 5 – INSPECTION

1/2019 MC405C-3 5-23

Crane

• Look around and below the boom and post and

look for any oil leak or similar. Be especially

careful to check up the derrick cylinder and

lower part of the winch motor near the post. If

you find any abnormality, repair.

• Check each part of the post for cracks,

excessive deformation, contamination and

others. In addition, check bolts, nuts, pins and

piping joints for any looseness, drop, damage

and other matters. Be especially careful to

check for looseness of decelerator mounting

bolt of the post, slewing ring or slewing device.

If you find any abnormality, repair.

• Check each part of the boom for cracks,

excessive deformation, contamination and

others. In addition, check bolts, nuts, pins and

piping joints for any looseness, drop, damage

and other matters. Be especially careful to

check for excessive abrasion and damage of

the boom support pin or derrick support pin. If

you find any abnormality, repair.

• Check for excessive damage and deformity of

the over winding weight wire rope of the

overwinding alarm device at the tip of the

boom. If there is any abnormality, repair.

• Check for sagged electrical wire, loosened

connection and trace of burns. If you find any

abnormality, repair.

Wire Ropes

For more informationo on wire ropes, see "Wire

Rope" on page 5-65.

• Check the wire ropes for damage, deformation,

wear, twists, kinks, corrosion, etc. If you find

any abnormality, replace

• Check the bound condition of the wire rope

ends. If you find any loosened wire rope end,

replace.

• Check for irregular winding of the wire ropes

(wind drum). If you find any irregular winding,

rewind.

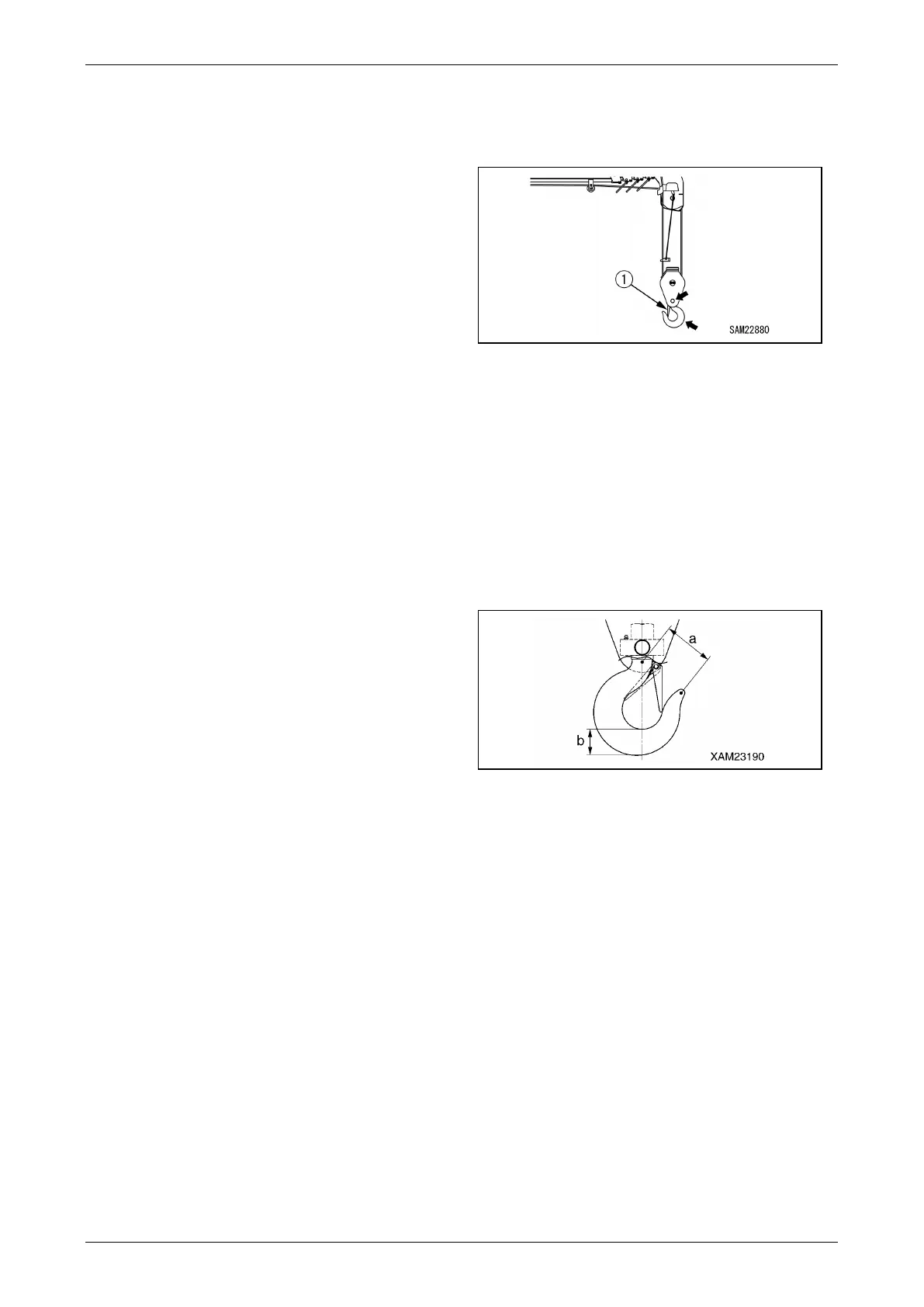

Hook Block

• Verify that the wire rope latch (1) functions

normally. If there is any abnormality, repair.

Fig. 5-29

• Rotate the hook and verify that the hook rotates

smoothly and that trunnion does not emit any

abnormal sound.

If there is any abnormality, repair.

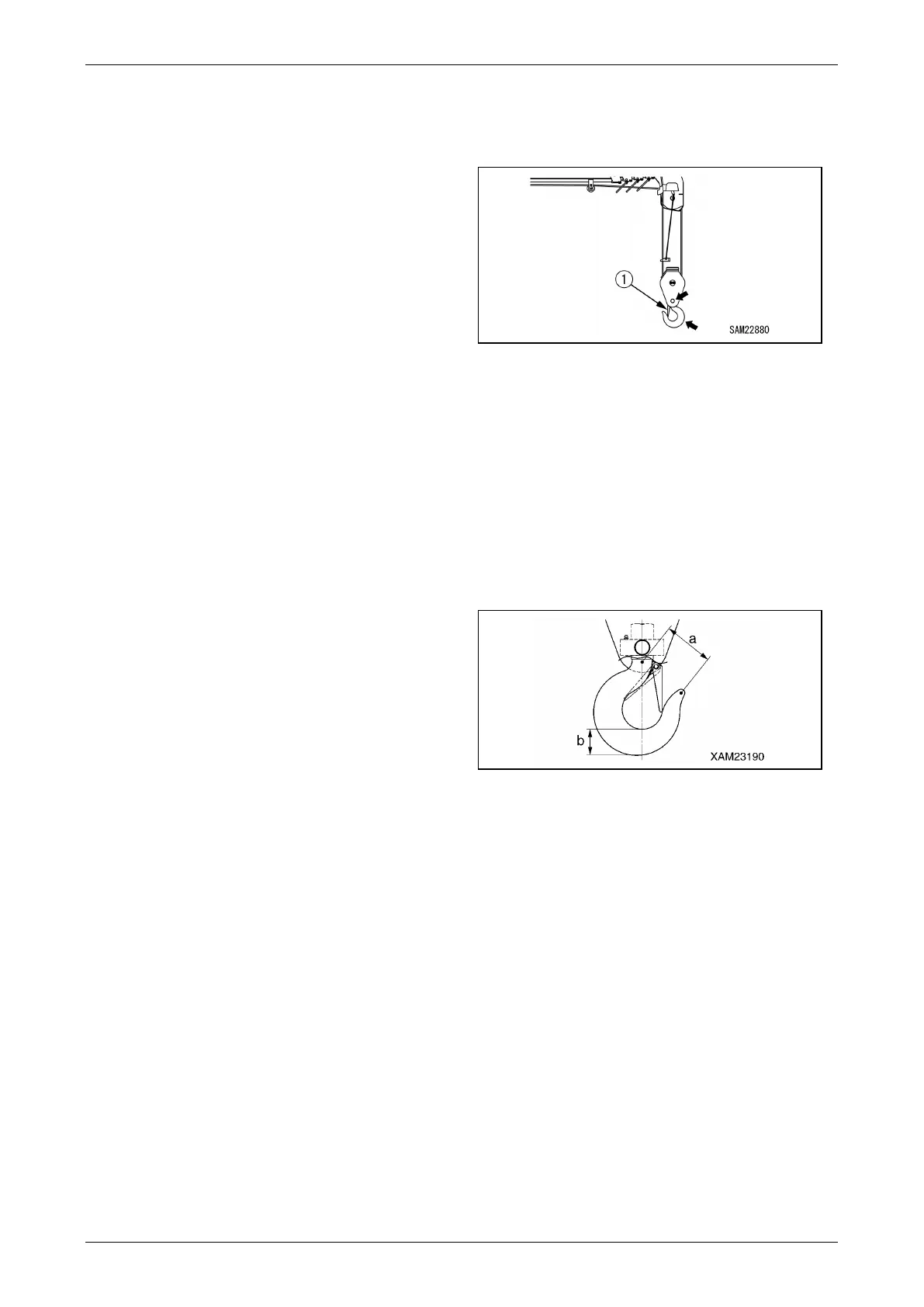

• Check the hook for any crack or excessive

deformation.

If there is any abnormality, repair.

• If dimension a between the punch marks

punched on the hook became "105 mm or

more" or the hook lower part dimension b

became "49.5 mm or less", replace the hook.

Fig. 5-30

Outriggers

• Look below each of the outriggers and check

for any oil leak or similar. Be especially careful

to check below the outrigger cylinders. If you

find any abnormality, repair.

• Check each of the rotaries, outriggers, holders

and outrigger cylinders for cracks, excessive

deformation, contamination and others. In

addition, check bolts, nuts, pins and piping

joints for any looseness, drop, damage and

other matters. If you find any abnormality,

repair.

• Check for sagged electrical wire, loosened

connection and trace of burns. If you find any

abnormality, repair.

• Pull out the position pin of each of the

outriggers, rotate the relevant rotary and verify

that the operation is smooth. If you find any

abnormality, repair.

Loading...

Loading...