Mini-Crawler Crane M A E D A Section 5 – FLY-JIB INSPECTION AND MAINTENANCE

1/2019 MC405C-3 5-87

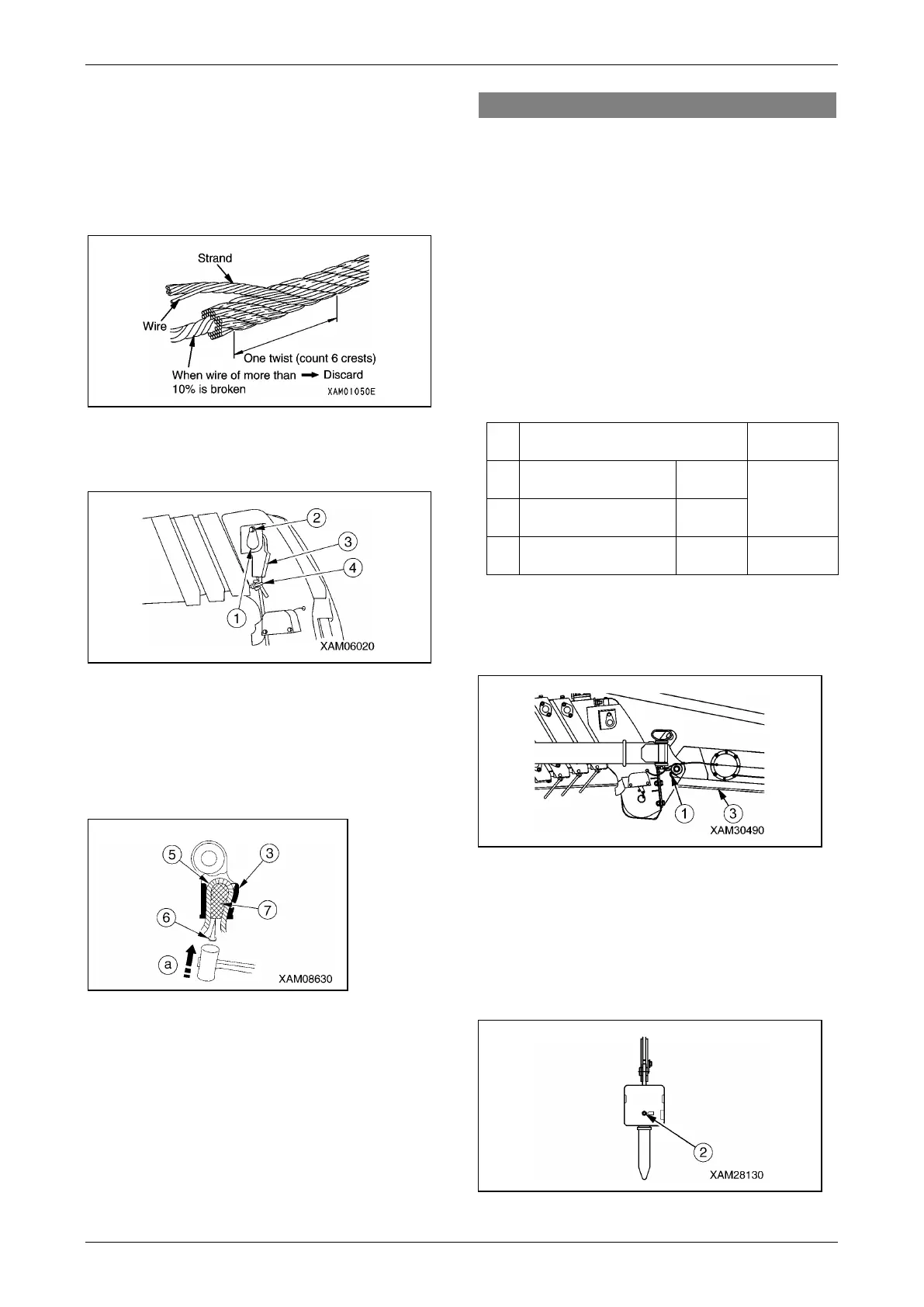

Criteria for Winch Wire Rope Replacement

A wire rope undergoes wear and tear over time.

Prompt replacement is required if any of the

following events appears in the wire rope.

• 10% or more of strands (except a filler wire) in

a twist of the wire rope (6 crests) is broken.

Fig. 5-203

NOTICE: Replace the wire rope for winching if 9

strands or more are broken.

Fig. 5-204

• Wear equivalent to 7% or more of a nominal

diameter occurs in the wire rope diameter.

NOTICE: Replace an 8-mm-dia wire rope if it is

7.5mm in diameter.

• A kink is formed.

Fig. 5-205

• Considerable deformation or corrosion is

developed.

• A faulty end socket is used.

Maintenance Every 250 Hours

Greasing Machine Units

CAUTION:

• Grease type varies with greasing points.

Failure to grease properly may cause the

machine to shorten its useful life. See the

following table for grease types.

• Greasing a new machine is required once

every 10 hours until the machine attains the

first 100 hours of operation. After that

period grease as required.

• Use proper grease specified below according to

the greasing points.

No.

Greasing point

1

Greasing of the

boom mounting pin

1 place

Lithium

grease

2

Greasing of the

hook block

1 place

3

Greasing of the

winch wire rope

1 piece Rope oil

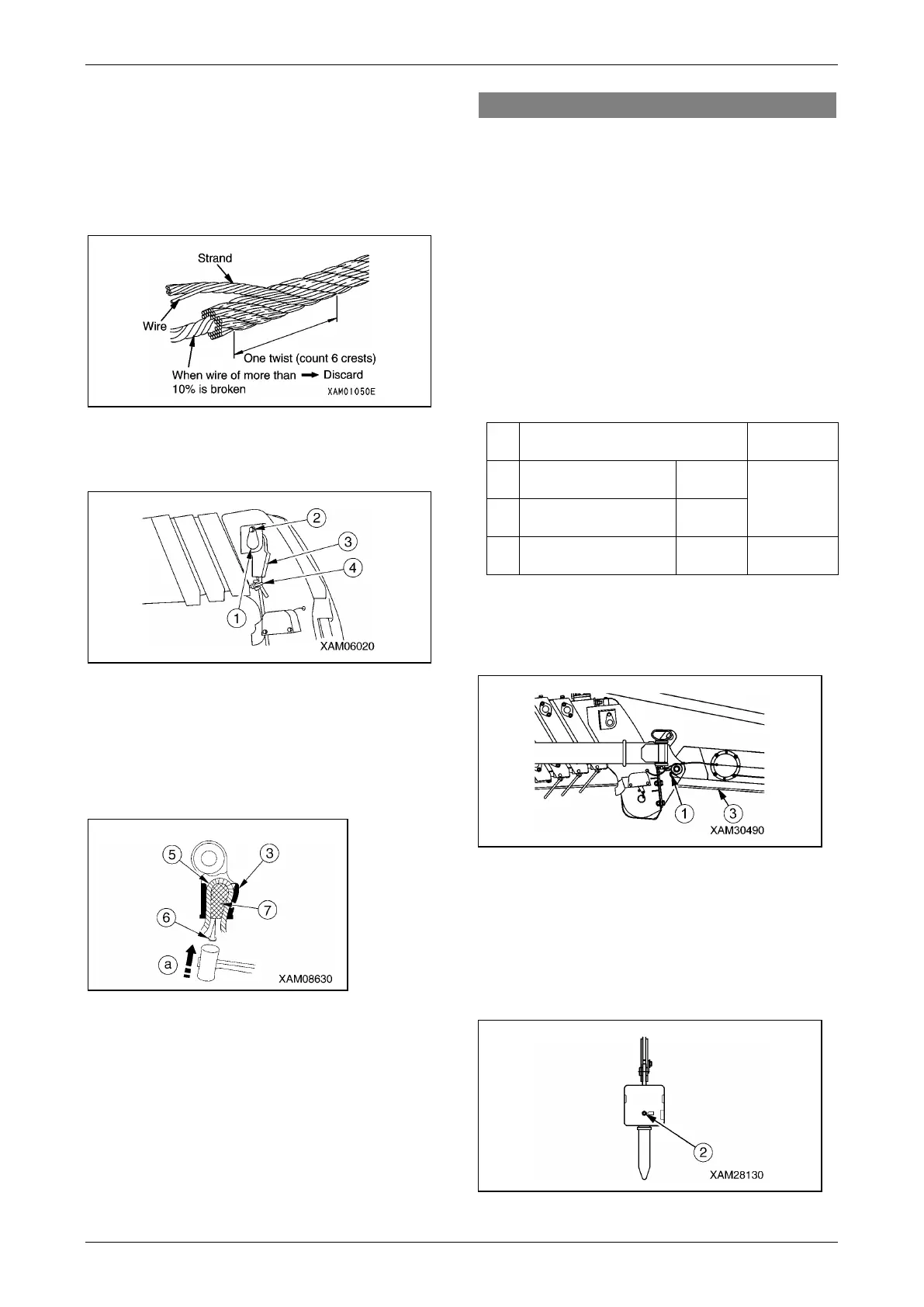

1. With the use of the grease gun, grease the

greasing points (No.1, 2) specified in the

above table through corresponding grease

plugs.

Fig. 5-206

2. Wipe off old grease squeezed out after

greasing.

3. Apply red rope grease to prevent wire rope

abrasion and rust formation.

With the rope surface cleaned, grease the

rope with a brush.

Fig. 5-207

Loading...

Loading...