Mini-Crawler Crane M A E D A Section 5 – PERIODIC MAINTENANCE

1/2019 MC405C-3 5-45

Tension Adjustment

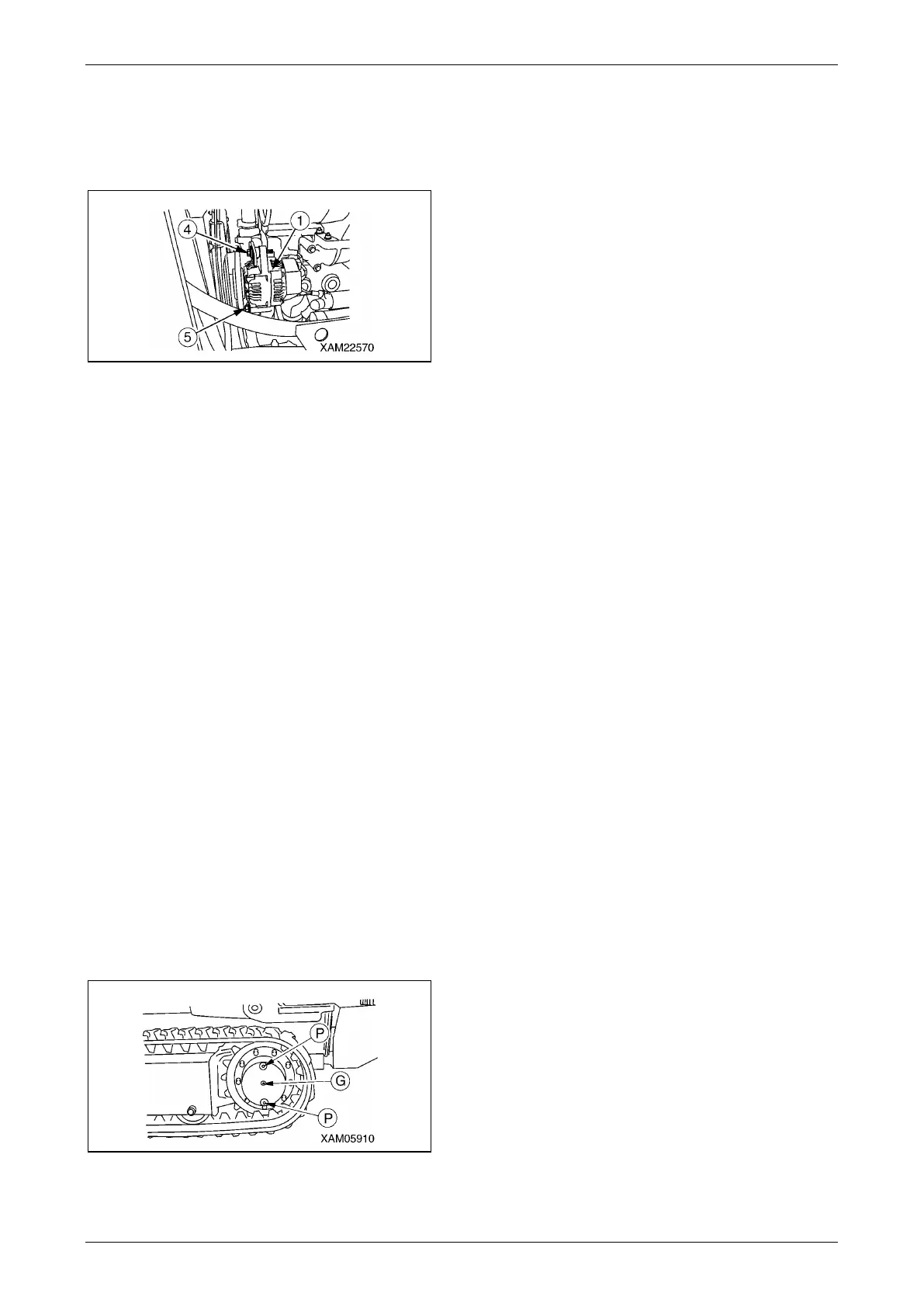

• Have a wooden bar available.

1. Insert the bar between the alternator (1) and

cylinder block.

Fig. 5-92

2. Loosen the lower bolt (5) and adjusting bolt

(4).

3. Move the alternator (1) until strain of the belt

(3) falls within the standard value range,

pulling the bar toward you.

4. Tighten the alternator lower bolt (5) and then

the adjusting bolt (4) to secure the alternator

(1).

5. Reattach the machinery cover as described

in "Installing Machinery Cover" on page 5-

18.

Check / Refill Oil in Travelling Motor

Reduction Gear Case

CAUTION:

• For more information on the which oil to be

used, see "LUBRICATING OIL" on page 5-

14.

• Use seal tape, etc. at the thread of the filler

plug to stop the oil leak and securely

tighten the plug after refilling with the oil.

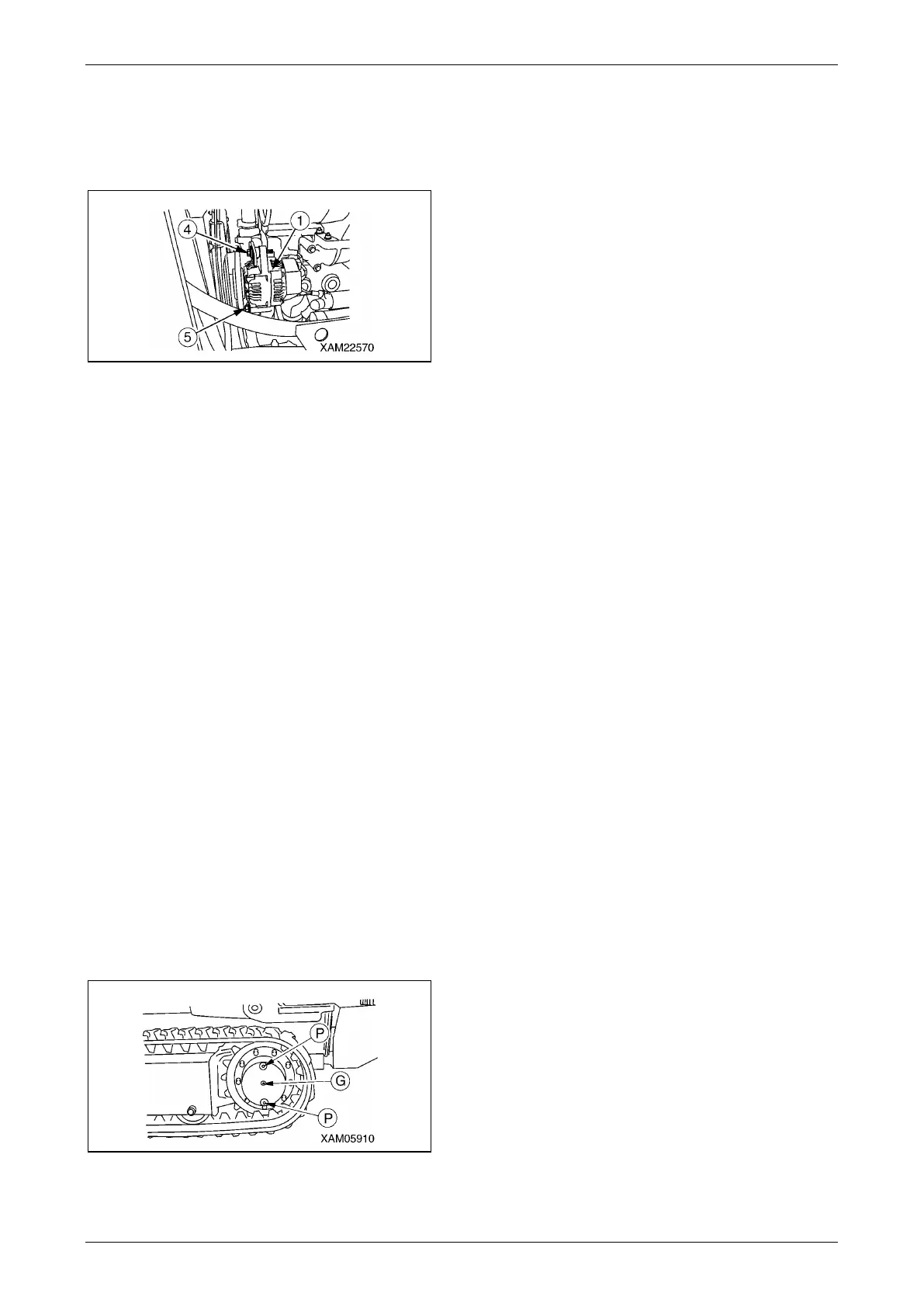

1. Move the machine forward and backward to

position it immediately above the drain plug

(P) of the travelling motor reduction gear

case.

Fig. 5-93

NOTICE: This machine is equipped with two

drain plugs (P). Either drain plug must be

positioned directly underneath the machine.

2. Remove the oil inspection plug (G) of the

travelling motor reduction gear case, and

make sure oil is drained from the plug hole.

3. In the case of insufficient oil in the casing,

remove the top drain plug (P) and replenish

gear oil through the plug hole.

NOTICE:

• Replenish the gear oil until it exudes from the

oil inspection plug.

• Wipe off the oil completely if spilled.

4. Put in the top drain plug (P) and oil

inspection plug (G), and secure the plugs

upon completion of oil inspection and

replenishment.

Loading...

Loading...