Section 5 – FLY-JIB INSPECTION AND MAINTENANCE Mini-Crawler Crane M A E D A

5-86 1/2019 MC405C-3

Winch and Boom

WARNING! Whilst performing the function

check for winch and boom, ensure the safety

of personnel so that the hook and boom do

not interfere with any personnel or objects.

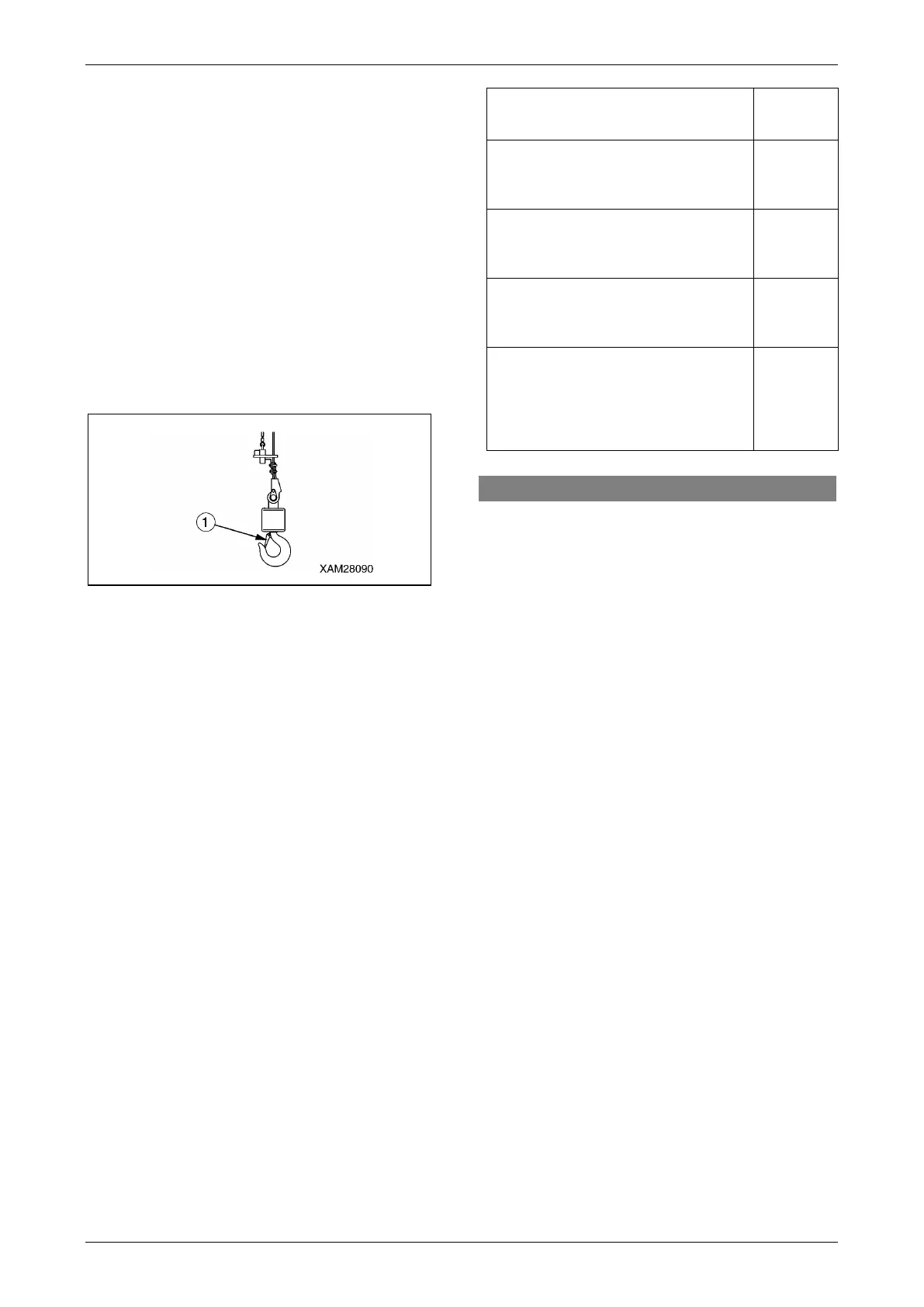

1. Check abnormal noise from boom, hook and

any area of wire rope during crane

operation.

2. Operate crane without load and check for

loose or missing bolts.

3. Check hook for deformation, abnormal noise

from bearing and correct function of wire

rope latch, (1).

Fig. 5-202

Moment Limiter for Operation (Fly-jib

Mode)

WARNING! If you find any abnormality with

the moment limiter, immediately contact us or

our sales service agency.

1. Turn starter switch ON.

2. Check rotary lamp. First, red revolving light

will appear for approximately 2 seconds, and

then turn to green revolving light.

3. Check moment limiter display. Ensure that

error code do not appear in Rated load

display.

4. Ensure that fly-jib mode is effective. ("Jib"

shall be displayed in Boom length display

alternately with boom length in fly-jib mode)

5. Start engine and operate crane as specified

below to check correct indication of moment

limiter.

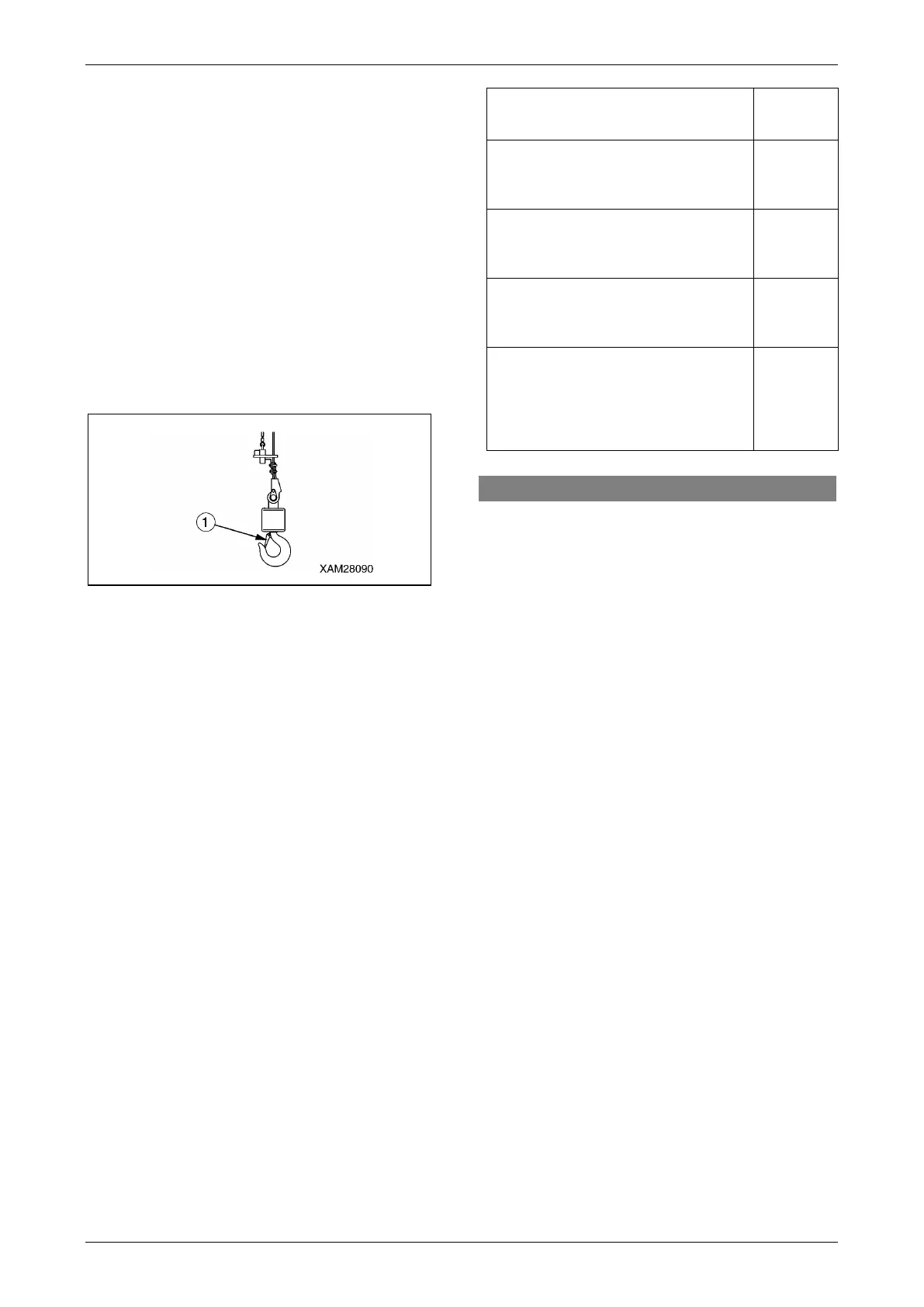

Crane motion and moment limiter

indication

moment

Boom is extended to 13.0m or longer

then lowered. Check boom angle

indication when rated load display

55°

Boom is extended to 13.0m or longer

then raised. Check boom angle

indication when rated load display

76°

Indication of working radius display,

when boom is extended to "16.5m",

with full extension of five stages and

boom angle is raised to "72°".

7.0 ± 0.1m

Indication of actual load display when

a rated weight is prepared and lifted.

• Indication shall be identical to total

weight including sling equipment.

• Some deviation may be allowed

under certain boom conditions.

Actual

load

Initial 10 Hour Maintenance

The following maintenance should be performed

after 10-hour operation, limited to the first

maintenance of a new machine.

Greasing Fly-Jib Foot Pin

For maintenance items and procedure, see

"Maintenance Every 250 Hours" on page 5-87.

Irregular Maintenance

Replacement Winch Wire Rope

WARNING! Always wear leather gloves when

replacing the wire rope.

CAUTION:

• The diameter of the wire rope is to be

measured at points where the wire

repeatedly runs through the sheave. A mean

value needs to be determined through

three-way measurement. (A measurement

should be performed at several points,

spacing between the points.)

• DO NOT use the old wire rope regardless of

the frequency of use.

Loading...

Loading...