Mini-Crawler Crane M A E D A Section 5 – PERIODIC MAINTENANCE

1/2019 MC405C-3 5-51

Maintenance Every 1000 Hours

Perform this maintenance in tandem with

maintenance every 50/100/250/500 hours.

Replace Oil in Hydraulic Oil Tank

WARNING!

• All the parts will be at elevated

temperatures immediately after engine

operation, which urges you not to replace

oil. Always perform replacement with the oil

cold.

• Potential gush of oil may occur upon

removing the filler cap of the hydraulic oil

tank.

Be sure to relieve internal pressure by

slowly rotating the filler cap before cap

removal.

• Make sure the filler cap is closed properly

after replenishment of the oil.

Potential fall of the filler cap during

operation may occur if disregarded, which

could cause boiling oil to gush that results

in burns.

CAUTION:

• For more information on the which oil to be

used, see "LUBRICATING OIL" on page 5-

14.

• Place the machine in travel position for oil

quantity inspection. Oil quantity inspection

with the machine in working position may

deceive your eyes to deem the quantity of

oil low. Owing to improper judgment, the oil

may be supplied at excessive amount.

• The engine must be at halt until piping and

hydraulic equipment is filled with oil after

replacement of the hydraulic oil filter.

• Oil replenished should remain below "H"

(upper limit) on the level gauge. Excessive

oil replenishment may cause the oil to gush

from the air breather during machine

travelling and crane operation, which could

result in burns.

• Keep impurities out of the filler cap when

replenishing oil.

• Oil drain pan: An 70-litre container

• Quantity of oil for replacement: 55L

1. Place the machine on a level surface.

2. Remove the machinery cover as described

in "Removing Machinery Cover" on page 5-

18.

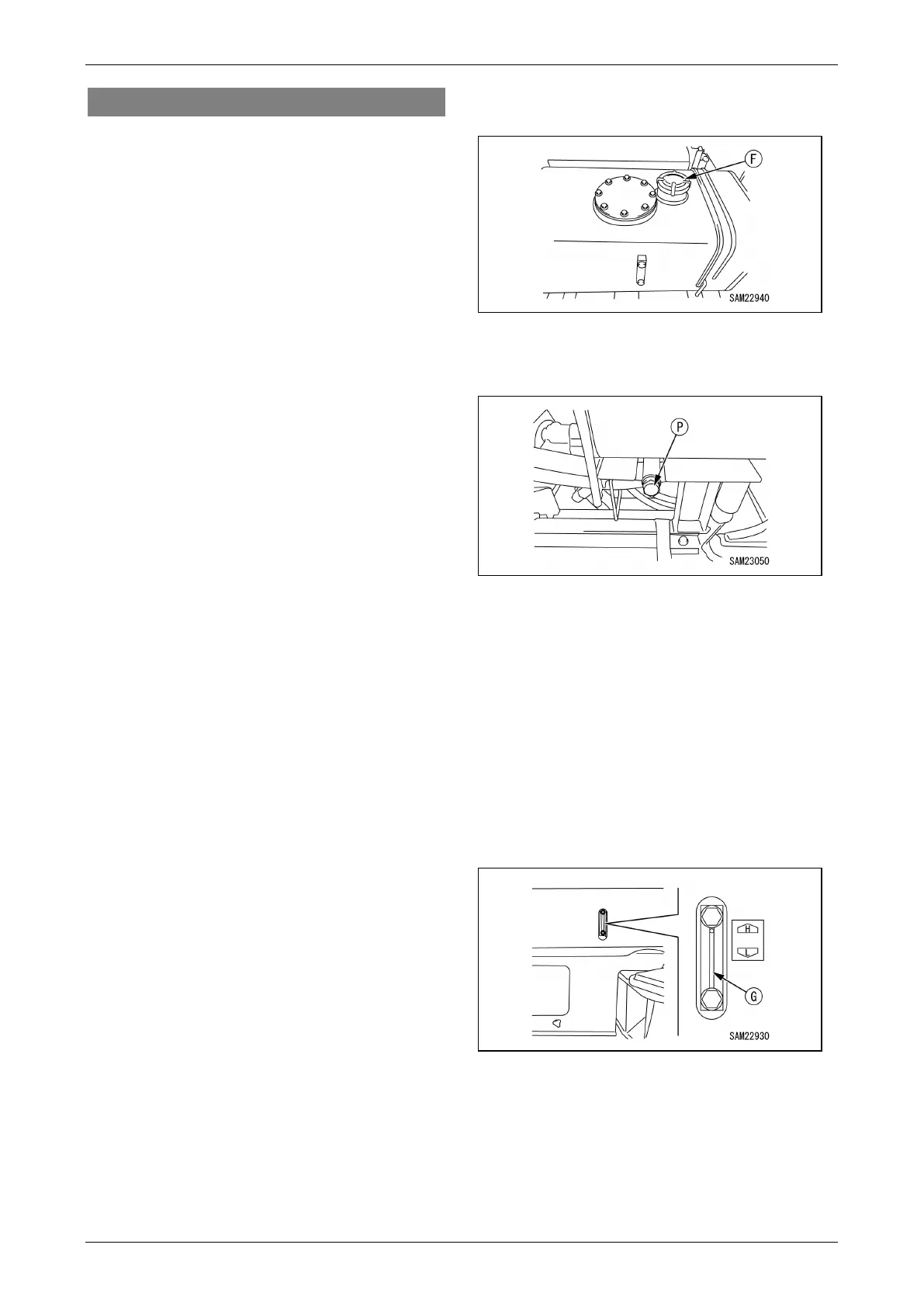

3. Remove the filler cap (F) located on top of

the hydraulic oil tank.

Fig. 5-104

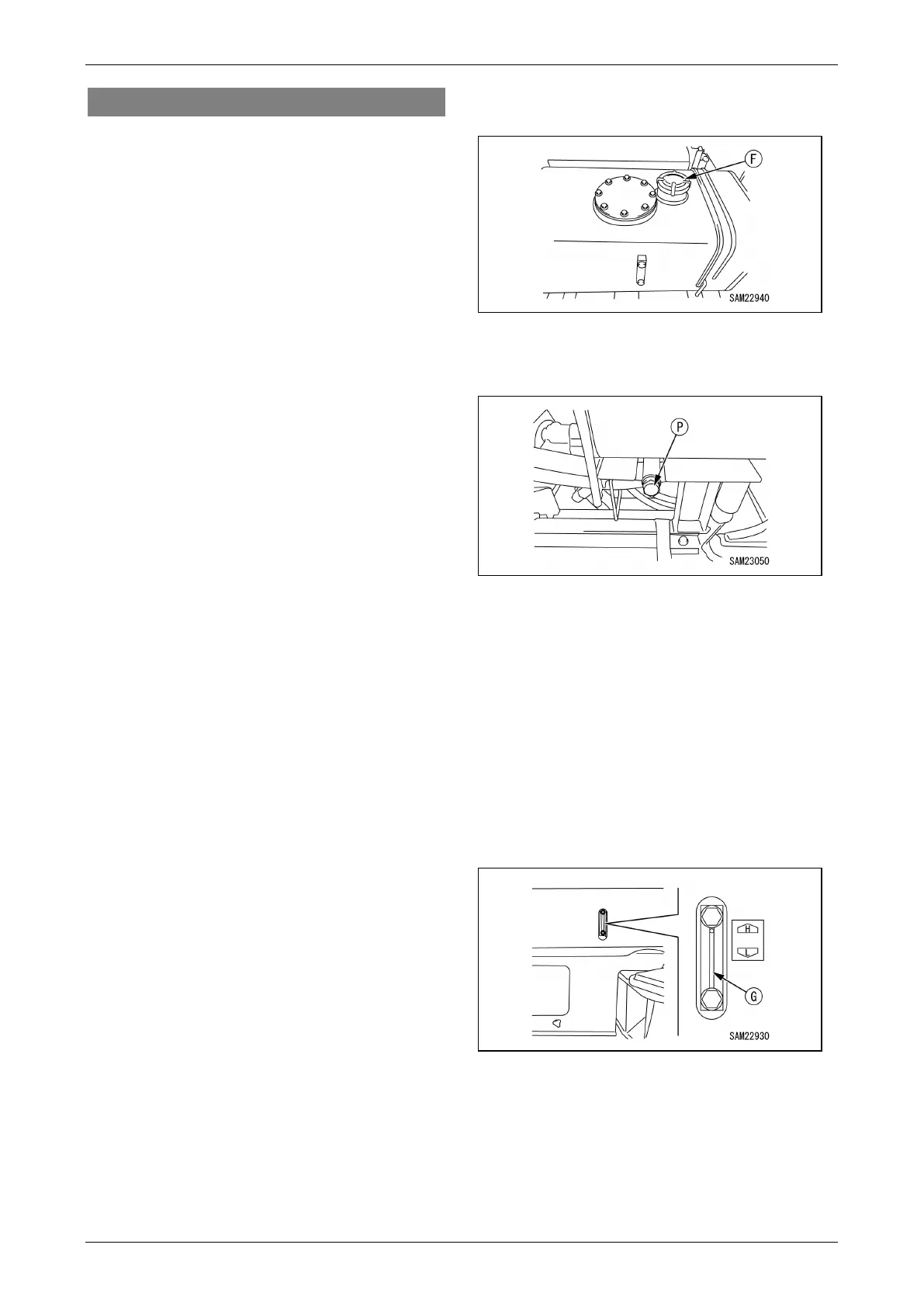

4. Place a drain pan directly underneath the

drain plug (P) to receive drained oil.

Fig. 5-105

5. Remove the drain plug (P) slowly to drain

the oil, keeping from contact with draining

oil.

6. Check the drained oil. If check finds a

considerable amount of metal powder and

foreign objects, contact our sales service

agency

7. Put in the drain plug (P) and secure it.

8. Supply the hydraulic oil to a specified level

point from the filler cap (F), visually checking

the oil level gauge (G).

Fig. 5-106

9. Close the filler cap (F) after replenishment of

the oil.

NOTICE: Wipe off the oil completely if spilled.

Loading...

Loading...