Mini-Crawler Crane M A E D A Section 5 – PERIODIC MAINTENANCE

1/2019 MC405C-3 5-53

7. Put in the drain plug (P) and secure it.

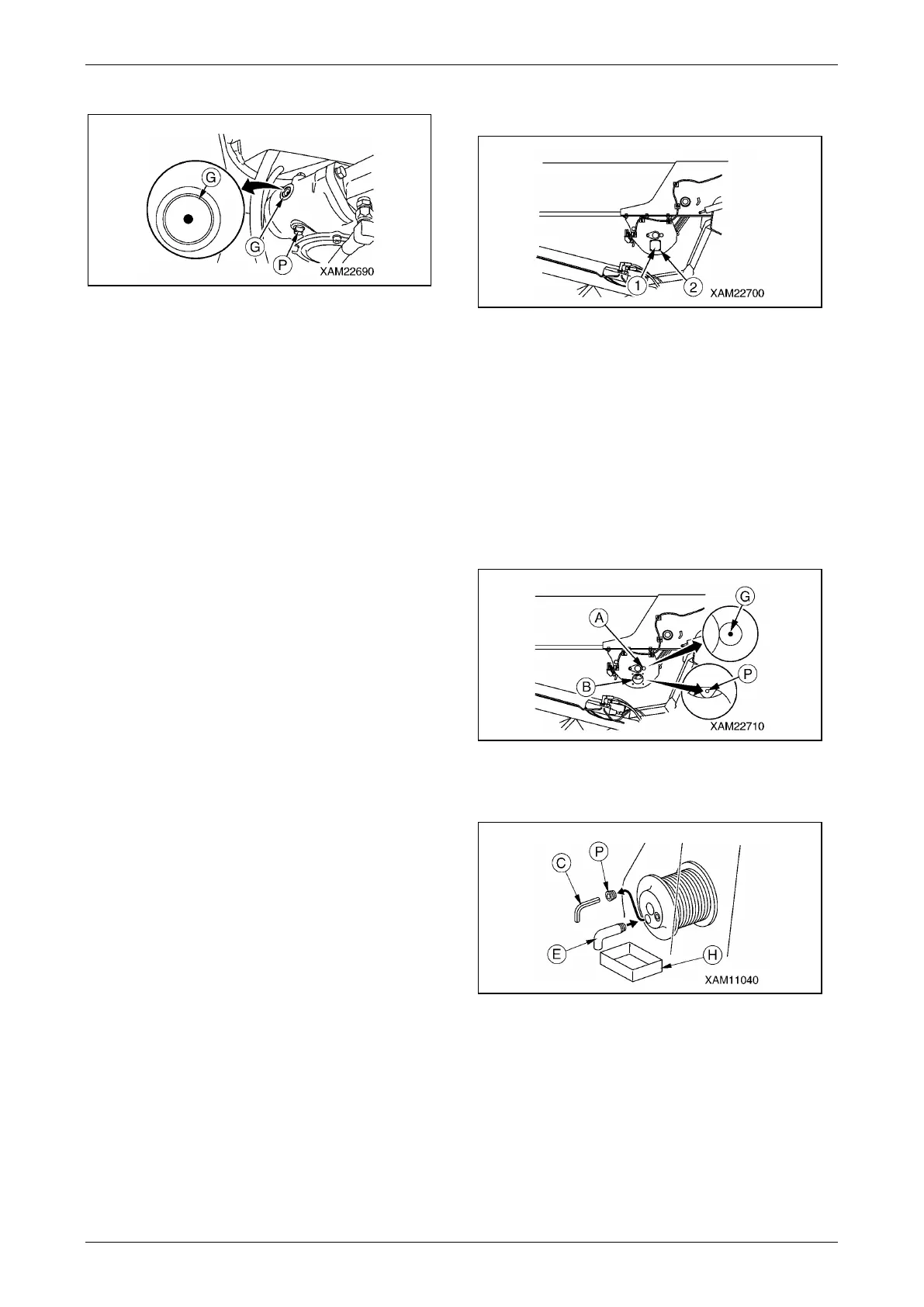

Fig. 5-109

8. Supply the gear oil to the slewing reduction

gear case through the filler plug (F).

NOTICE:

• The gear oil must be filled from the filler cap, up

to the midpoint of the site gauge (G).

• Wipe off the oil completely if spilled.

9. Put in the filler plug (F) and secure it after oil

replacement.

10. See "OUTRIGGER STOWING" on page 4-

49 to stow the outriggers.

Replace Oil in Winch Reduction Gear

Case

WARNING! Oil will be at elevated

temperatures immediately after engine

operation, which urges you not to unplug the

inspection port and drain port. Unplug the

port with the oil cold.

CAUTION:

• For more information on the which oil to be

used, see "LUBRICATING OIL" on page 5-

14.

• Use seal tape, etc. at the thread of the filler

plug to stop the oil leak and securely

tighten the plug after refilling with the oil.

• Oil drain pan: A 1-litre container

• Hexagonal wrench for plug removal: 8mm

• Quantity of oil for replacement: 0.5L

1. Place the machine on a level surface.

2. See "OUTRIGGER SETTING" on page 4-42

to set the outriggers.

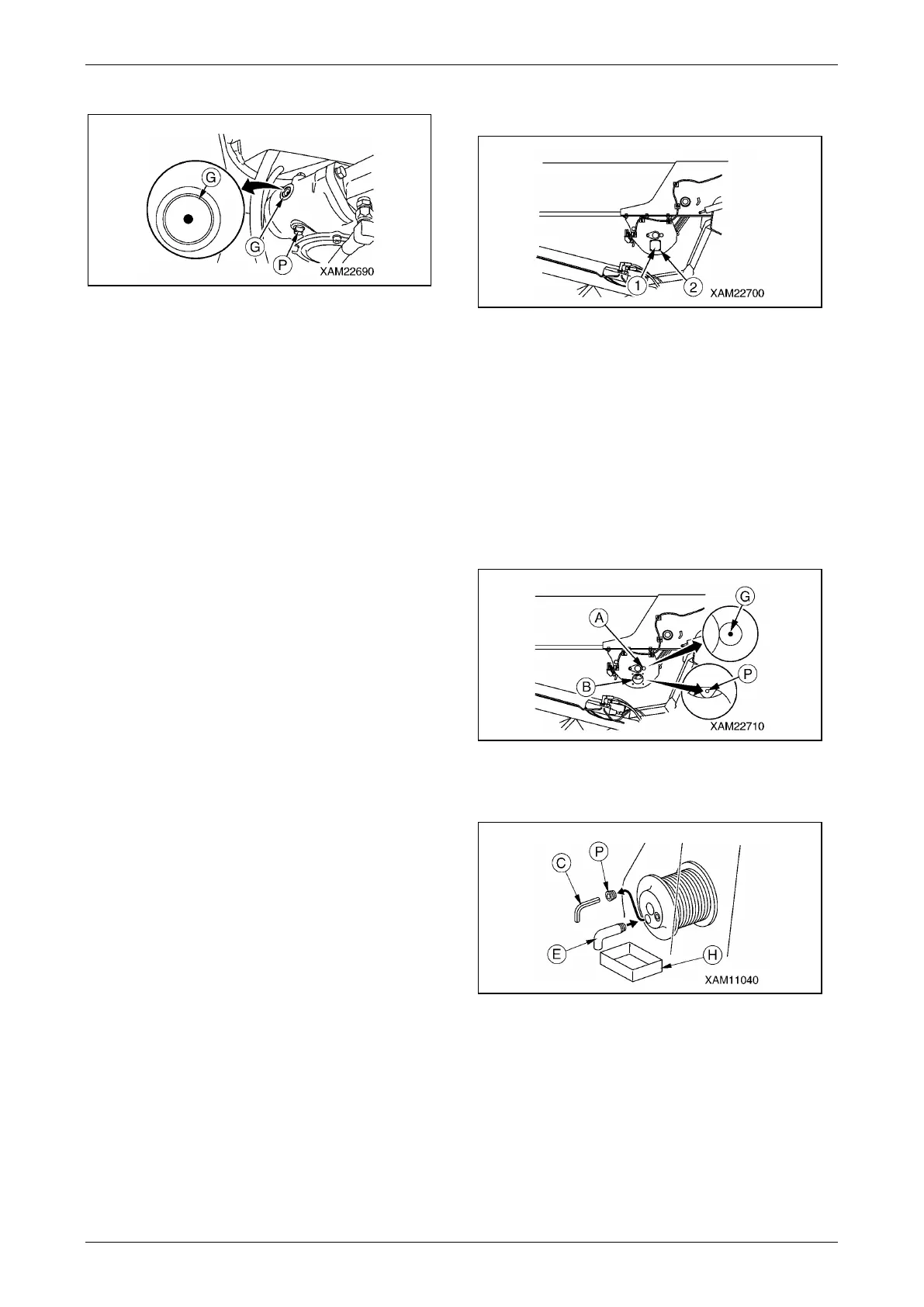

3. Remove the four mounting bolts (2) and

remove the cover (1).

Fig. 5-110

4. Rotate the winch slowly to a point where the

oil inspection plug (G) and drain plug (P)

come in sight.

(1) Stop the winch at a point where the oil

inspection plug (G) can be seen through

the post side inspection hole (A).

(2) Stop the winch at a point where the

drain plug (P) of the winch reduction

gear case can be seen above the

inspection hole (B).

Fig. 5-111

5. Use the hexagonal wrench (C) to remove the

drain plug (P).

Fig. 5-112

6. Install the elbow (E) to the screw hole of the

drain plug (P) for draining oil.

Loading...

Loading...