Mini-Crawler Crane M A E D A Section 5 – FLY-JIB INSPECTION AND MAINTENANCE

1/2019 MC405C-3 5-85

Pre-Start – Before Starting Engine

Check the following in this section without

starting the engine and before starting work

every day.

Boom and Frame

• Check each part of the boom and frame for

cracks, excessive deformation, contamination

and others. In addition, check bolts, nuts and

pins for any looseness, drop, damage and

other matters. If you find any abnormality,

repair.

Wire Ropes

For more information, see "Wire Rope" on page

5-65.

• Check the wire ropes for damage, deformation,

wear, twists, kinks, corrosion, etc. If you find

any abnormality, replace

• Check the bound condition of the wire rope

ends. If you find any loose wire rope ends,

replace.

Fly-jib Fix Bolts

DANGER! If any damage found on fly-jib fix

bolt, please exchange it to new one right

away.

Breakage of bolt will cause fly-jib to fall off.

• Check if there is any cracks, damage, or

squash on screw thread on threaded portion of

bolt.

If cracks, damage or squash on screw thread is

found, change the bolt to new one even it is

earlier than expected bolt life.

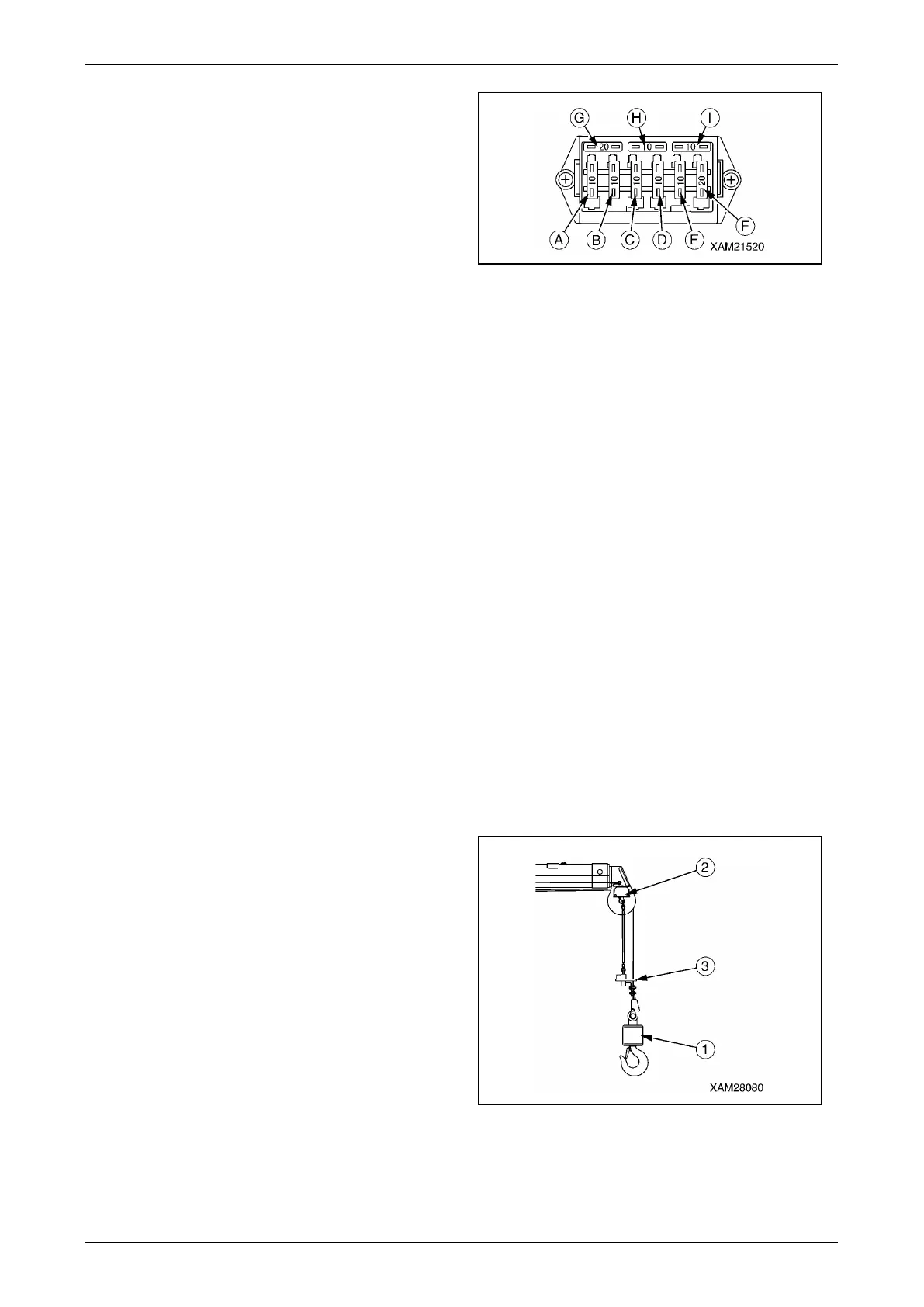

Electrical Wiring (Fuse Box)

WARNING! If fuses are brown frequently or if

you find the trace of a short circuit created in

the electrical wiring, be sure to find the cause

and fix the problem.

Check the fuse at the lower section of the

instrument panel for damage and meltdown and

if the fuse of specified capacity is being used.

If a fuse has melted down or the trace of an

open/short circuit is found in the electrical wiring,

ask us or our sales service agency for repair.

Fig. 5-200

Pre-Start – After Starting Engine

Check the followings in this section after starting

the engine and before starting work every day.

CAUTION: The checkups described in this

section should be carried out after starting

the machine.

See "STARTING ENGINE" on page 4-18 and

later to execute the engine startup, travelling

operations, outrigger operations and crane

operations.

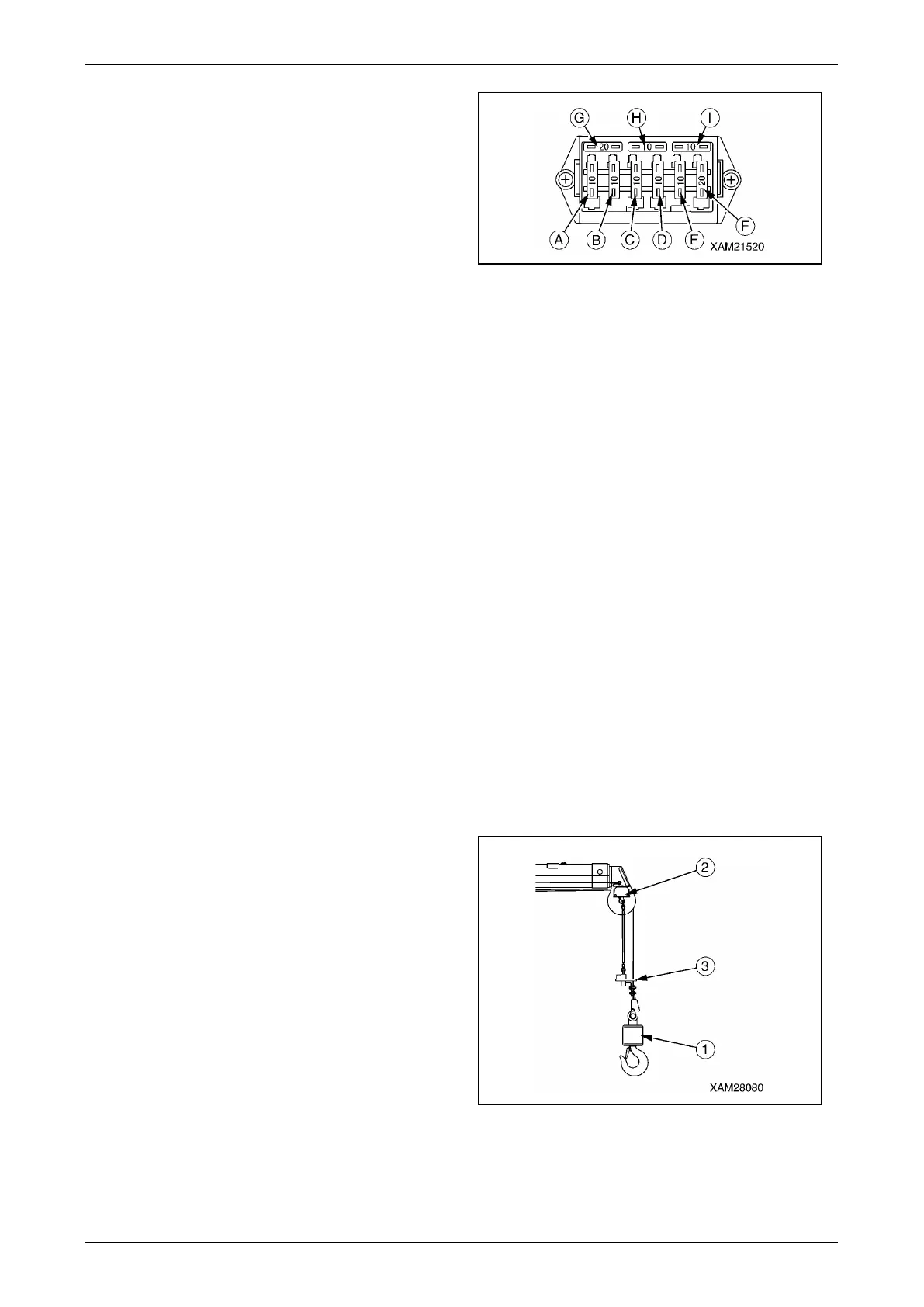

Over Winding Detector

Over wind the hook block (1), and raise the hook

with winch and extend the boom, and verify that

the buzzer sounds and an audible message

saying "Over hoisted" is spoken, the hook raising

operation and boom extending operation should

stop.

If these events do not happen, the over winding

detector (2) may be faulty.

If the alarm does not stop, the over winding

detector may be faulty or the circuit may be open.

Ask us or our sales service agency for repair.

Fig. 5-201

Loading...

Loading...