Section 5 – PERIODIC MAINTENANCE Mini-Crawler Crane M A E D A

5-50 1/2019 MC405C-3

(3) Allow all the outriggers to be extended,

referring to "OUTRIGGER SETTING" on

page 4-42. Extend and retract the

outrigger cylinder, keeping the machine

down on the ground.

Always stop the outrigger cylinder

approx. 100mm back from the stroke

end when operating the cylinder.

Repeat this task 4 to 5 times.

9. Reattach the machinery cover as described

in "Installing Machinery Cover" on page 5-

18.

Slew Ring Mounting Bolt Inspection

WARNING!

• If the slew ring mounting bolts become

loose and break, there is a risk of serious

injuries due to the upper part of the crane

becoming detached and toppling. Be sure to

inspect the slew ring mounting bolts, and

retighten them to the specified torque if

they are loose.

• Be sure to replace the slew ring mounting

bolts periodically. The bolts should be

replaced every 7 years or after 7,000 hours,

whichever comes sooner.

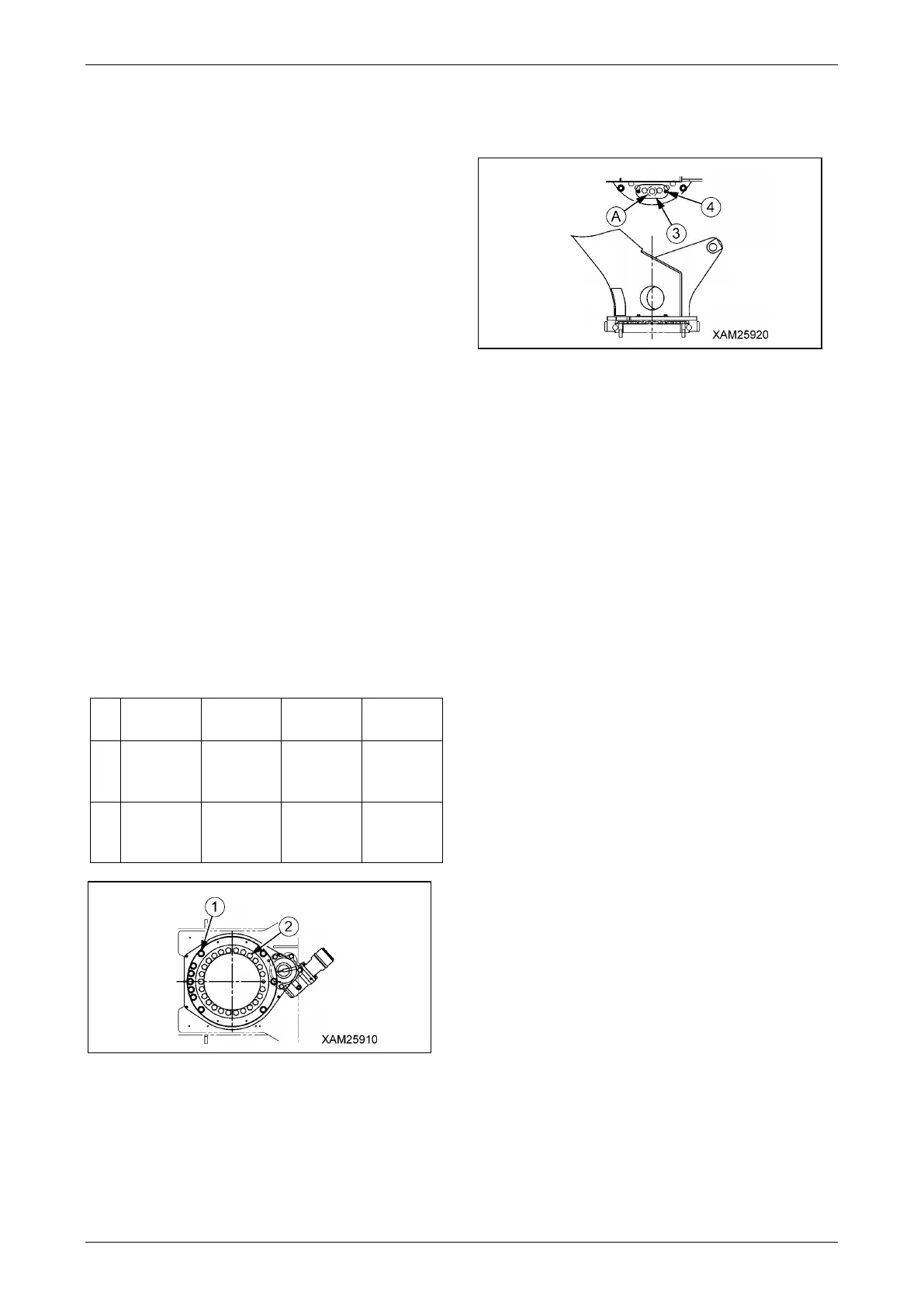

Slew ring mounting bolt tightening torque

No.

Dimensions

(1)

inner ring

M20 25

363 to

392 Nm

(2)

outer ring

M18 10

235 to

265 Nm

Fig. 5-102

Inspect the inner ring mounting bolts (2) as

follows.

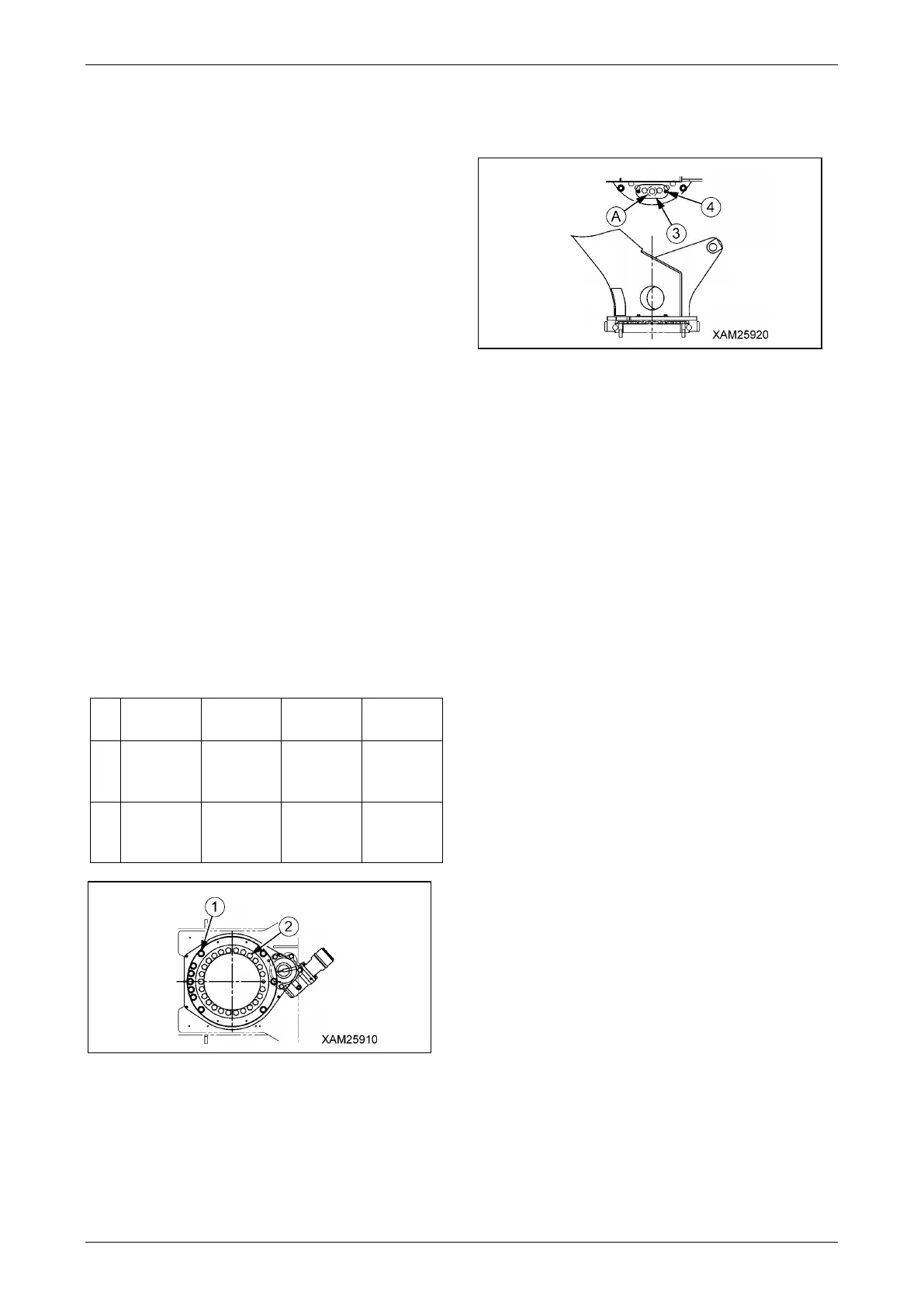

1. Remove the two mounting bolts (4) and

remove the inspection cover (3) to the right

of the slew post.

Fig. 5-103

2. Rotate the post to position each bearing

inner ring side mounting bolt (2) in the

middle of the inspection opening (A), and

inspect all of the mounting bolts (2) to

confirm that none are loose, missing, or

damaged.

3. If any of the bolts are loose, retighten using

the tightening torques given in the table

above. If bolts are damaged or missing, they

should be replaced with new ones.

4. Once inspection is complete, reattach the

inspection cover (3).

Inspect the outer ring mounting bolts (1) as

follows.

1. Rotate the post to position each bearing

outer ring side mounting bolt (1) at the side

of the machine, and inspect all of the

mounting bolts (1) to confirm that none are

loose, missing, or damaged.

2. If any of the bolts are loose, retighten using

the tightening torques given in the table

above. If bolts are damaged or missing, they

should be replaced with new ones.

Replace Air Cleaner Element

CAUTION: For more information on

replacement procedure, see "Inspection,

Cleaning and Replacement of Air Cleaner" on

page 5-72.

Loading...

Loading...