Section 5 – GENERAL MACHINE MAINTENANCE Mini-Crawler Crane M A E D A

5-64 1/2019 MC405C-3

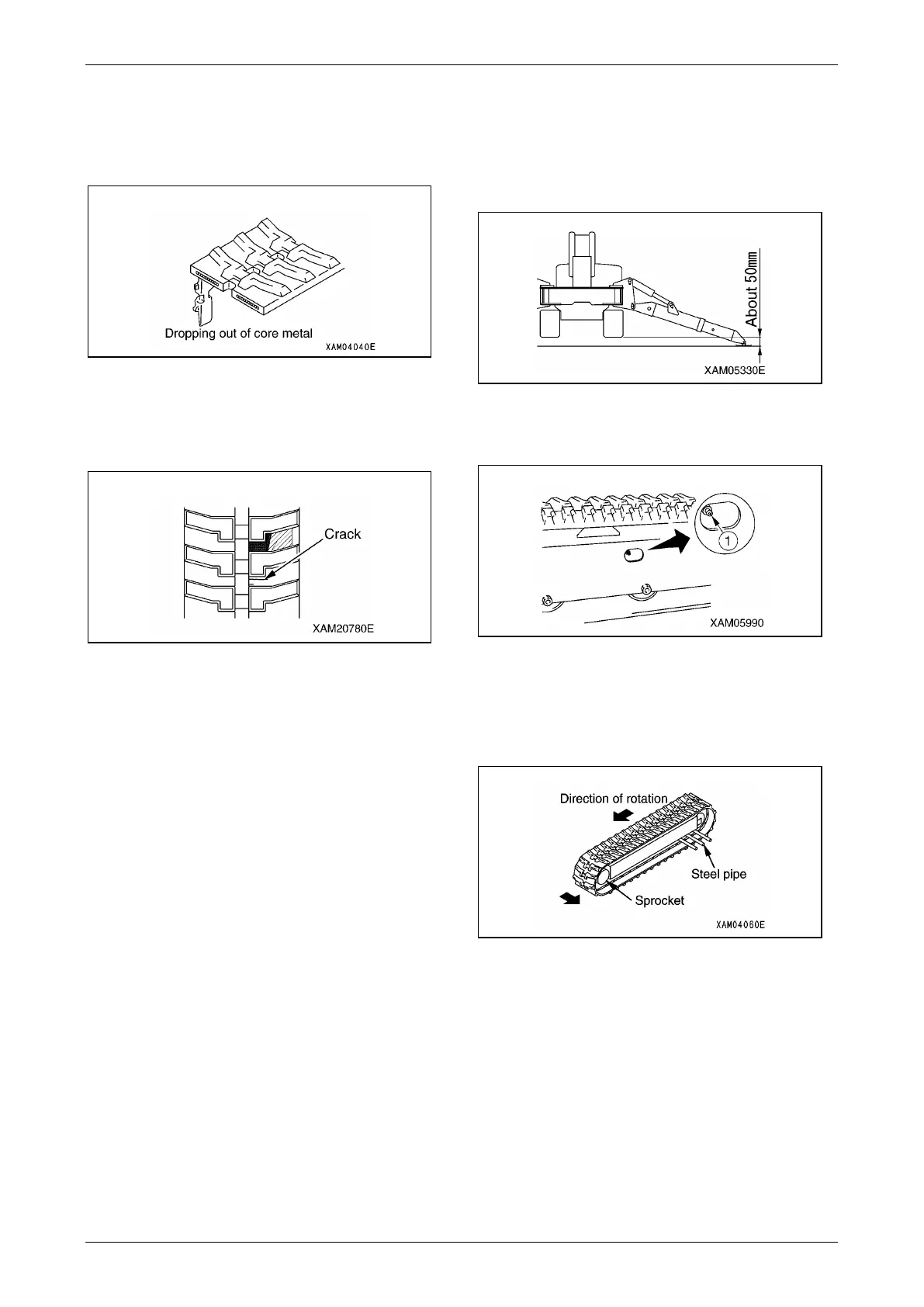

Fallen Core Metal

• If the core metal of the rubber track is fallen out

at more than 1 location, change the rubber

track with a new one.

Fig. 5-145

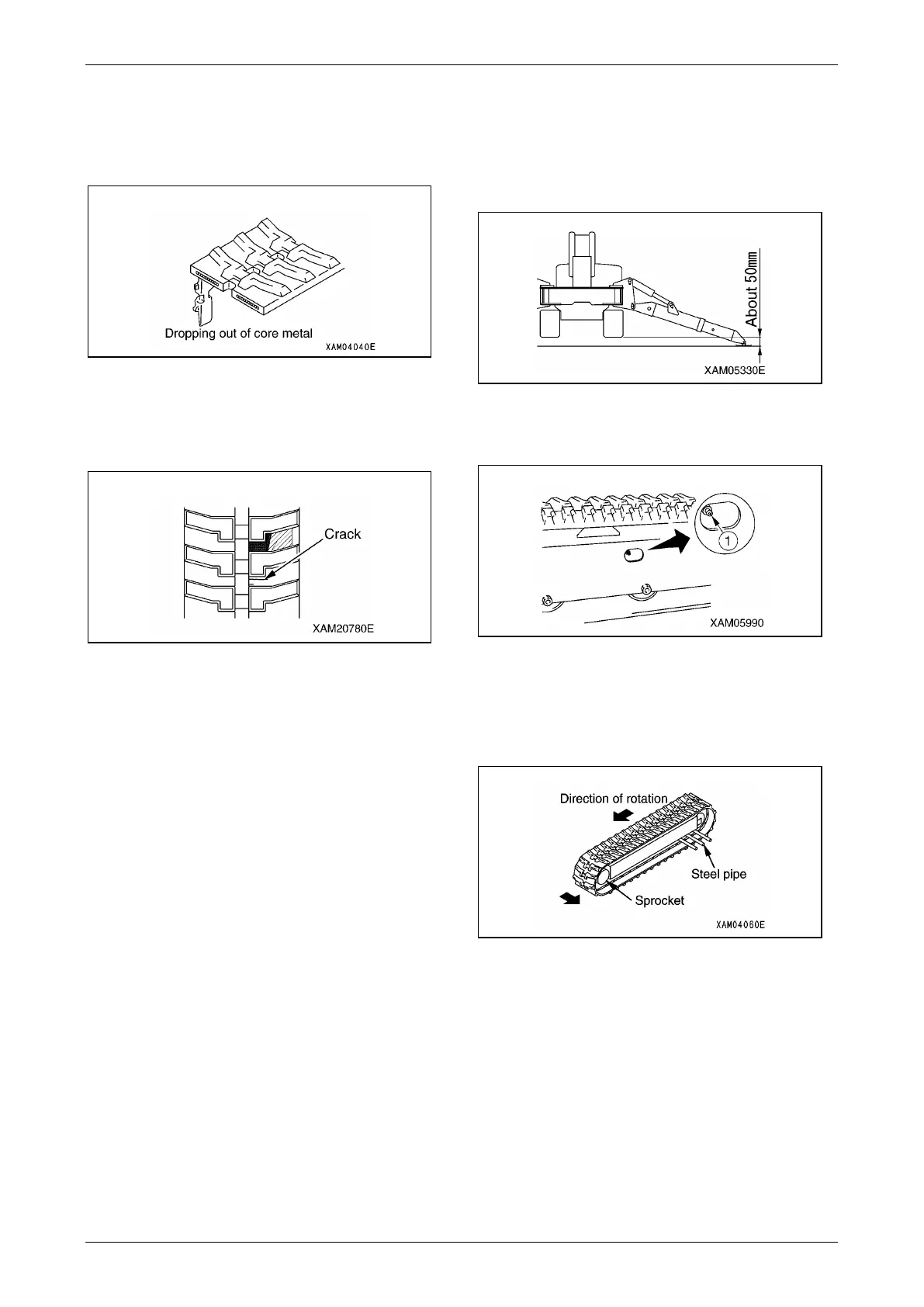

Cracks

• If there is a crack between rubber track lugs,

change the rubber track with a new one.

Fig. 5-146

Replace Rubber Track

WARNING!

• The inside of the tension adjusting device of

the rubber track is greased. Grease is under

high pressure associated with the tension

of the rubber track. Failure to follow

precautions stated below when removing

grease may lead to a serious accident due

to the grease valve being popping out.

• Only one full turn of the tension adjusting

grease valve is allowed to loosen. The

grease valve may pop out if disregarded.

• Always stand aside when conducting

tension adjustment of the grease valve to

circumvent potential dangers.

• Ensure that grease is completely removed

from the inside of the rubber track before

rotating the sprocket to remove the rubber

track.

Removal of Rubber Track

• Have a steel pipe available.

1. See "OUTRIGGER SETTING" on page 4-42

to set the outriggers and raise the rubber

track for about 50mm from the ground.

Fig. 5-147

2. Loosen the grease valve (1) gradually and

remove grease.

Fig. 5-148

3. Provide only one full turn of the grease valve

(1).

4. Insert the steel pipe between the idler and

rubber track. Rotate the sprocket backward.

Fig. 5-149

5. When the inserted steel pipe detaches the

rubber track from the idler, slide the crawler

in a lateral direction to remove it.

Loading...

Loading...