Section 5 – PERIODIC MAINTENANCE Mini-Crawler Crane M A E D A

5-52 1/2019 MC405C-3

10. Use the following procedure for air bleed.

(1) Start the engine with piping and

hydraulic equipment filled with oil.

Make sure the engine runs at low idle

for 10 minutes.

(2) Move the cylinders and winch motor

slowly with a crane control lever at low

idle speed.

Always stop the boom derricking

cylinder and telescoping cylinder

approx. 100mm back from the stroke

end when operating the cylinders.

Repeat this task 4 to 5 times.

(3) Allow all the outriggers to be extended,

referring to "OUTRIGGER SETTING" on

page 4-42. Extend and retract the

outrigger cylinder, keeping the machine

down on the ground.

Always stop the outrigger cylinder

approx. 100mm back from the stroke

end when operating the cylinder.

Repeat this task 4 to 5 times.

11. Reattach the machinery cover as described

in "Installing Machinery Cover" on page 5-

18.

Replace Oil in Slewing Reduction Gear

Case

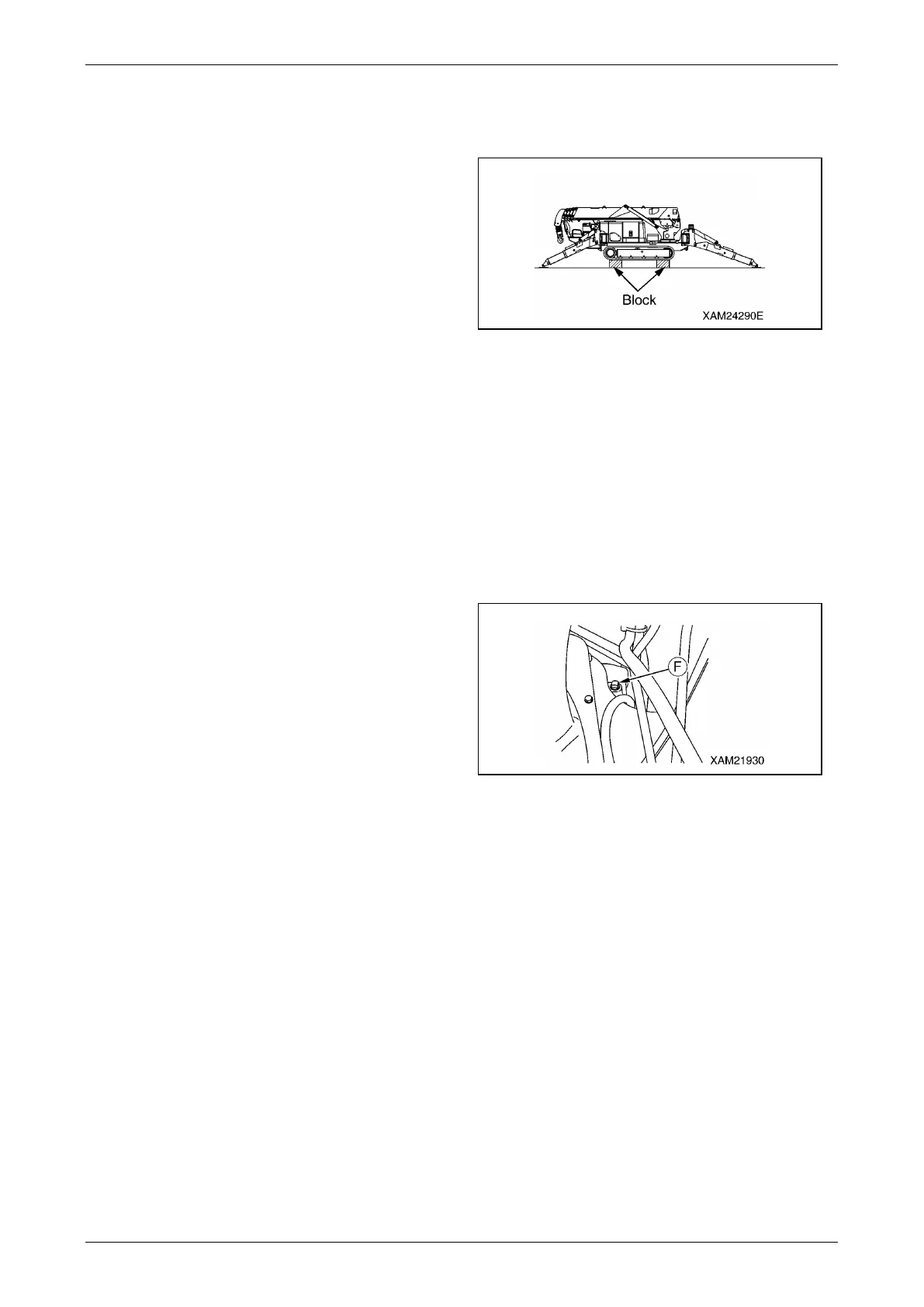

WARNING! The drain plug of the slewing

reduction gear case is located directly

underneath the machine.

Place the outriggers and raise the machine

50mm from the ground to allow a drain pan to

be placed under the machine for draining oil.

If the machine becomes unstable and

wobbles, insert supports under the front and

back of the machine to gain stability.

CAUTION:

• For more information on the which oil to be

used, see "LUBRICATING OIL" on page 5-

14.

• Use seal tape, etc. at the thread of the filler

plug to stop the oil leak and securely

tighten the plug after refilling with the oil.

• Oil drain pan: A 1-litre container

• Quantity of oil for replacement: 0.6L

1. Place the machine on a level surface.

2. See "OUTRIGGER SETTING" on page 4-42

to set the outriggers and raise the machine

from the ground.

Fig. 5-107

WARNING! Check the following before

crawling under the machine:

• Ensure that the outriggers are extended at

the maximum.

• Visually check the level to make sure the

machine in a horizontal position.

• Insert solid blocks between the crawler and

the ground to keep the machine raised.

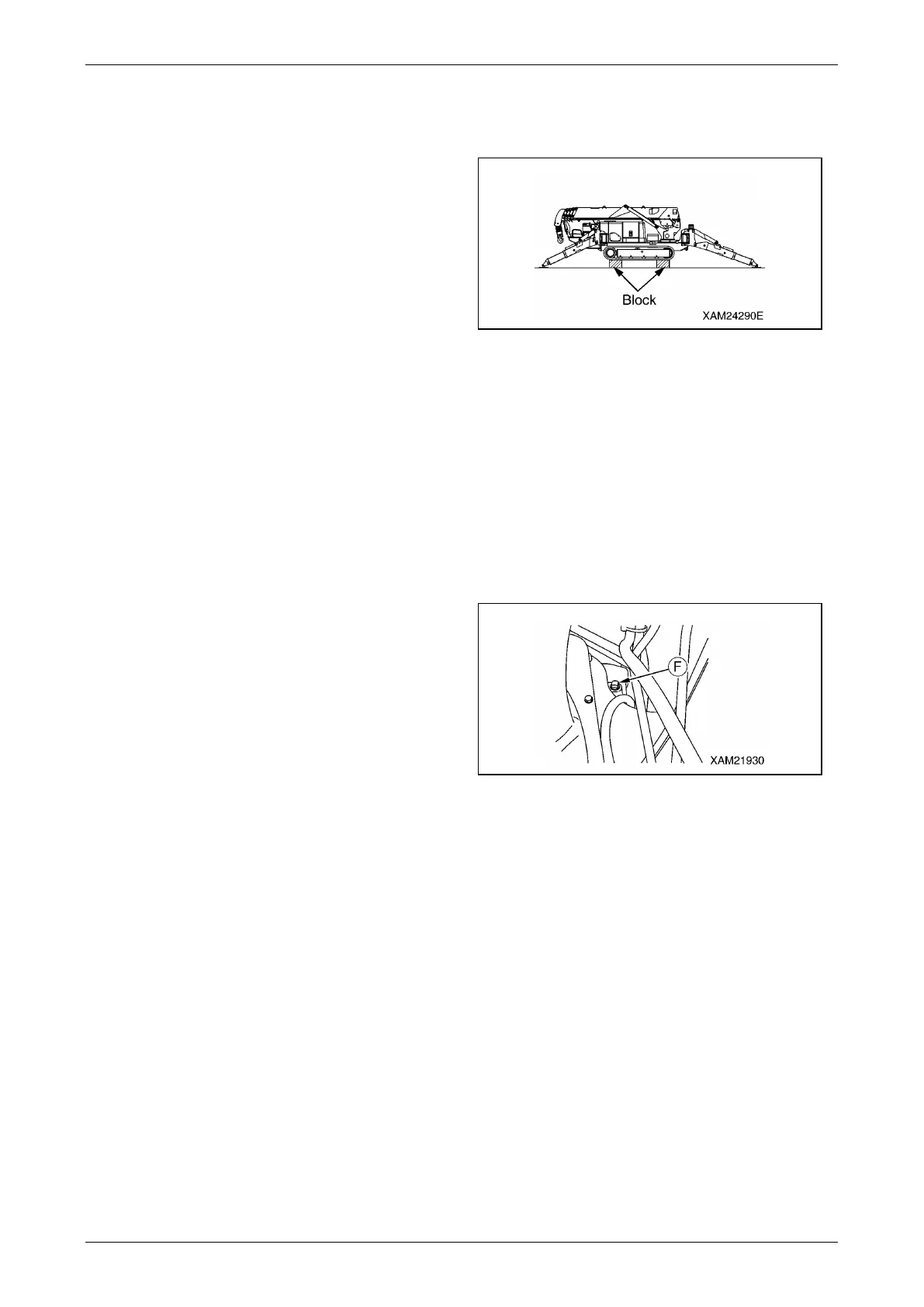

3. Remove the filler plug (F) from the slewing

reduction gear case.

Fig. 5-108

4. Crawl under the machine and place a drain

pan directly underneath the drain plug (P) of

the slewing reduction gear case to receive

drained oil.

5. Remove the drain plug (P) slowly to drain

the oil, keeping from contact with draining

oil.

6. Check the drained oil. If check finds a

considerable amount of metal powder and

foreign objects, contact our sales service

agency.

Loading...

Loading...