Section 5 – INSPECTION Mini-Crawler Crane M A E D A

5-32 1/2019 MC405C-3

Especially, with the new machine or when a new

part was installed, "initial slack" appears with 5 to

30 hours of operation after adjusting the tension

to the specified value.

Adjust the tension frequently until the period of

"initial slack" passes. This will prevent "rubber

track from coming off due to insufficient tension

on the rubber track".

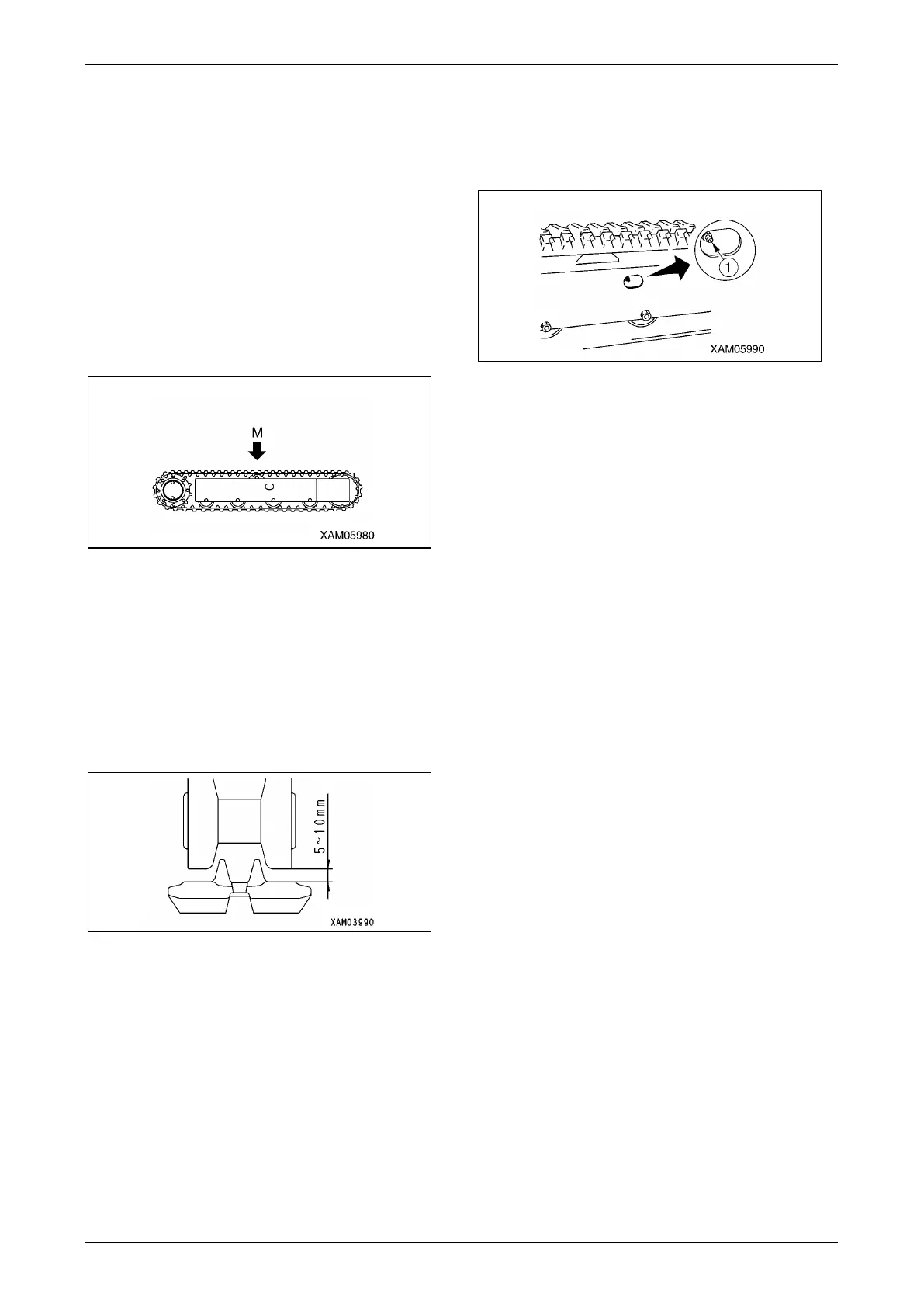

Tension Check

1. Move the left and right crawlers so that the

junction of the rubber track (indicated by M)

comes to the top centre between the axles.

Fig. 5-57

2. See "OUTRIGGER SETTING" on page 4-42

to set the outriggers and raise the crawlers

for about 50mm from the ground.

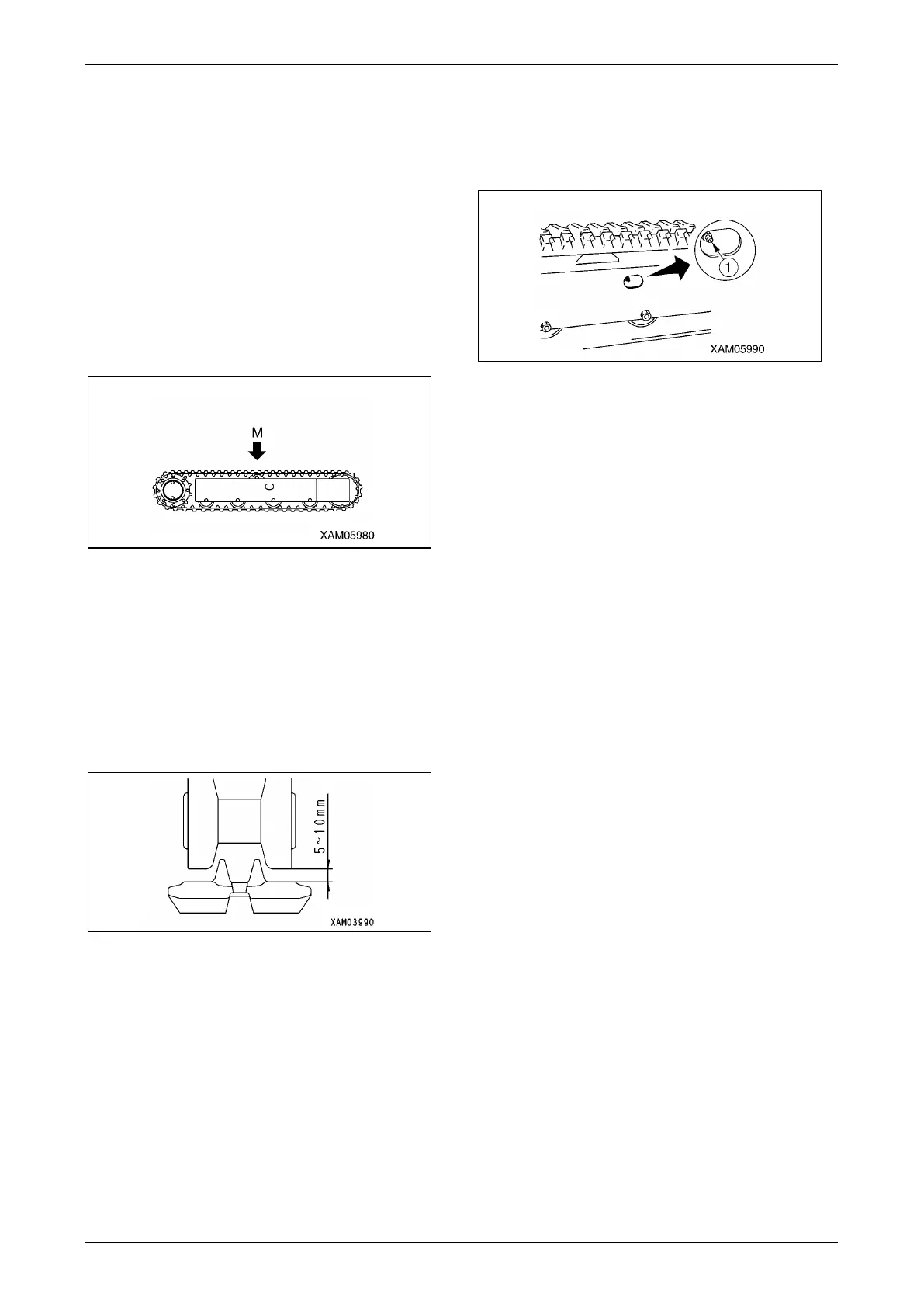

3. Measure the clearance between the wheel

tread of the track roller at centre and the

shoulder of the rubber track.

NOTICE: The clearance of 5 to 10 mm indicates

the standard tension.

Fig. 5-58

4. If the tension is out of the standard range,

see "Tension Adjustment" below to make

adjustments.

Tension Adjustment

If the "tension check" of the rubber track found

the tension lower than standard tension of the

rubber track, make adjustments as described

below.

Working with the loose rubber track (the tension

of the rubber track at 15 mm or more) will cause

run-off or early wear of the core metal.

• Loose Tension (Increase Tension)

Have a grease gun (pump) ready.

1. Inject the grease from the grease valve (1)

using the grease gun.

Fig. 5-59

2. Perform the following tasks to verify the

proper tension.

(1) See "OUTRIGGER STOWING" on page

4-49 to stow the outriggers and lower

the machine on the ground.

(2) Move the machine forward/backward.

(3) See "OUTRIGGER SETTING" on page

4-42 to set the outriggers and raise the

crawlers again for about 50mm from the

ground.

3. Perform the "tension check" of the rubber

track again.

If the tension is not appropriate, make

another adjustment.

4. See "OUTRIGGER STOWING" on page 4-

49 to stow the outriggers and lower the

machine on the ground.

• Tight Tension (Decrease Tension)

WARNING! Inside the rubber track tension

adjustment device has the grease sealed. The

grease is under high pressure due to the

tension of the rubber track.

Making adjustments without observing the

followings may cause the grease valve to fly

away, resulting in serious accidents.

• Do not loosen the grease valve for tension

adjustment for more than 1 turn. The grease

valve may pop out.

• Do not place yourself right in front of the

grease valve when adjusting the tension to

avoid any danger.

Loading...

Loading...