F

THE GEARBOX

\xxxw.‘

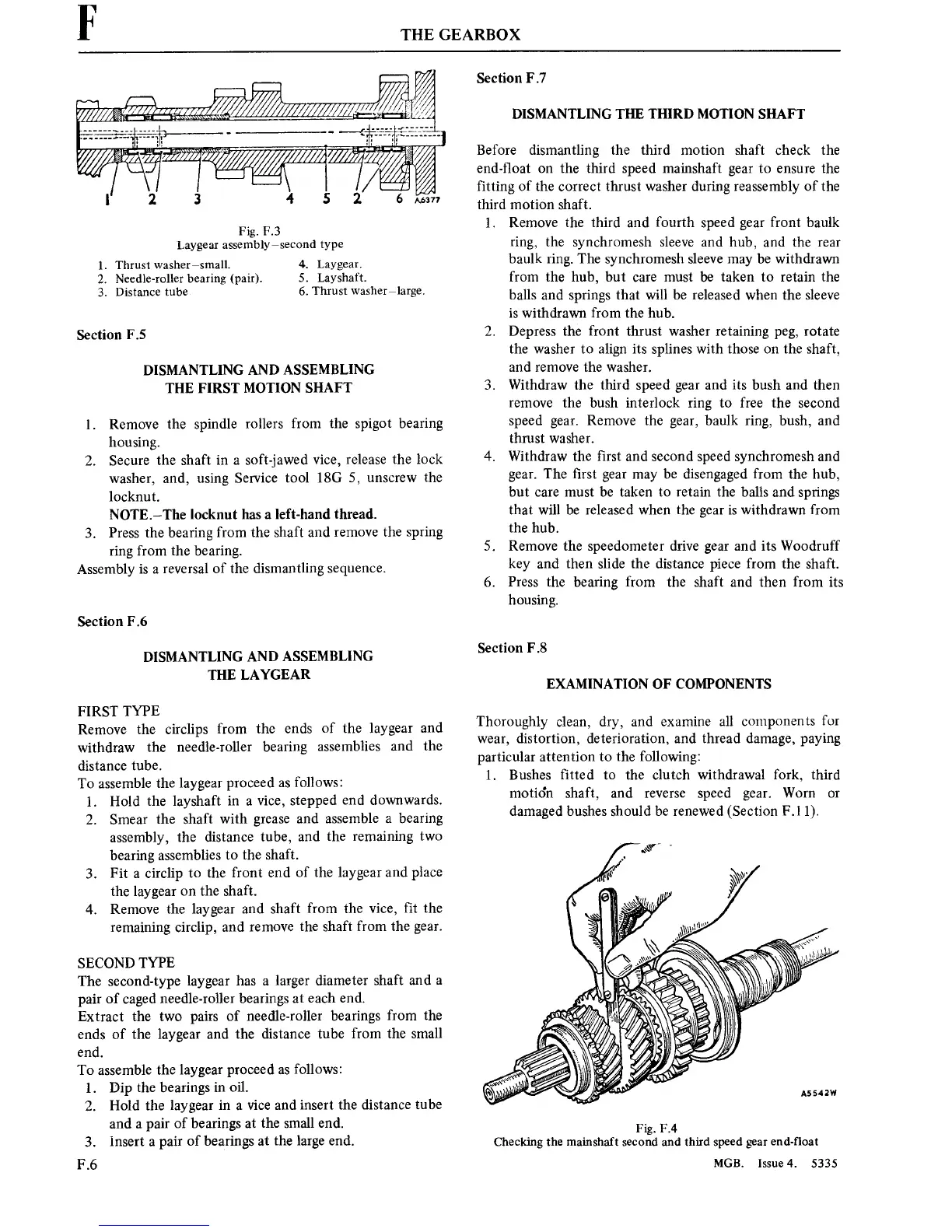

Fig.

F.3

Laygear

assemblyisecond

type

1.

Thrust

Washerismall.

4.

Laygear.

2.

Needle-roller

bearing (pair).

5.

Layshaft.

3. Distance

tube

6.

Thrust washerilarge.

Section F.5

DISMANTLING AND

ASSEMBLING

THE FIRST

MOTION SHAFT

1.

Remove

the

spindle rollers

from the

spigot

bearing

housing.

2.

Secure

the

shaft

in

a

soft-jawed

vice,

release

the lock

washer, and,

using

Service

tool 18G 5,

unscrew

the

locknut.

NOTE.~The

locknut has

a

left-hand thread.

3.

Press

the bearing

from the

shaft and

remove

the

spring

ring

from the bearing.

Assembly

is

a

reversal

of

the

dismantling

sequence.

Section F.6

DISMANTLING

AND

ASSEMBLING

THE

LAYGEAR

FIRST

TYPE

Remove

the

circlips

from the ends

of

the laygear

and

withdraw

the

needle-roller bearing

assemblies

and the

distance

tube.

To

assemble the laygear

proceed

as

follows:

1.

Hold

the

layshaft

in

a

vice,

stepped end

downwards.

2. Smear

the shaft with

grease

and

assemble

a

bearing

assembly,

the distance

tube, and the remaining

two

bearing

assemblies

to

the

shaft.

3.

Fit

a

circlip

to

the

front end

of the laygear and

place

the laygear

on

the

shaft.

4. Remove

the laygear

and

shaft from the

vice,

fit

the

remaining

circlip, and

remove

the

shaft from the

gear.

SECOND

TYPE

The

second-type laygear

has

a

larger diameter

shaft

and

a

pair

of caged

needle-roller

bearings

at

each end.

Extract

the

two

pairs

of

needle-roller bearings

from the

ends of the laygear

and the distance tube

from the

small

end.

To

assemble

the laygear

proceed

as

follows:

1.

Dip

the bearings

in

oil.

2.

Hold

the

laygear

in

a

vice

and

insert

the distance

tube

and

a

pair

of

bearings

at

the small end.

3. Insert

a

pair

of bearings

at

the

large

end.

F.6

Section F.7

DISMANTLING THE THIRD MOTION SHAFT

Before

dismantling the third

motion

shaft

check the

end-■oat

on

the third speed mainshaft

gear

to

ensure

the

fitting of the

correct

thrust washer during reassembly of the

third

motion

shaft.

1.

Remove

the third and

fourth

speed

gear

front

baulk

ring,

the synchromesh sleeve

and hub, and the

rear

baulk

ring.

The synchromesh sleeve

may

be

withdrawn

from the hub, but

care

must

be taken

to

retain

the

balls and

springs

that will be released when the sleeve

is

withdrawn from the hub.

2. Depress

the

front

thrust

washer

retaining

peg,

rotate

the washer

to

align

its

splines with those

on

the shaft,

and

remove

the washer.

3.

Withdraw the third speed

gear

and

its

bush and

then

remove

the

bush interlock

ring

to

free

the second

speed

gear.

Remove

the

gear,

baulk

ring,

bush,

and

thrust washer.

4.

Withdraw the ■rst and

second

speed synchromesh

and

gear.

The

■rst

gear may

be disengaged

from

the hub,

but

care

must

be taken

to

retain

the balls and

springs

that

will be released when the

gear

is

withdrawn from

the hub.

5. Remove

the speedometer drive

gear

and

its

Woodruff

key and then slide

the distance

piece

from

the

shaft.

6. Press

the

bearing

from the shaft

and

then from

its

housing.

Section F.8

EXAMINATION OF COMPONENTS

Thoroughly clean, dry, and

examine

all

components

for

wear,

distortion, deterioration, and

thread damage,

paying

particular

attention

to

the following:

1.

Bushes fitted

to

the

clutch withdrawal fork,

third

motio‘n

shaft,

and

reverse

speed

gear.

Worn

or

damaged

bushes should

be renewed

(Section

F.1

1).

A5542W

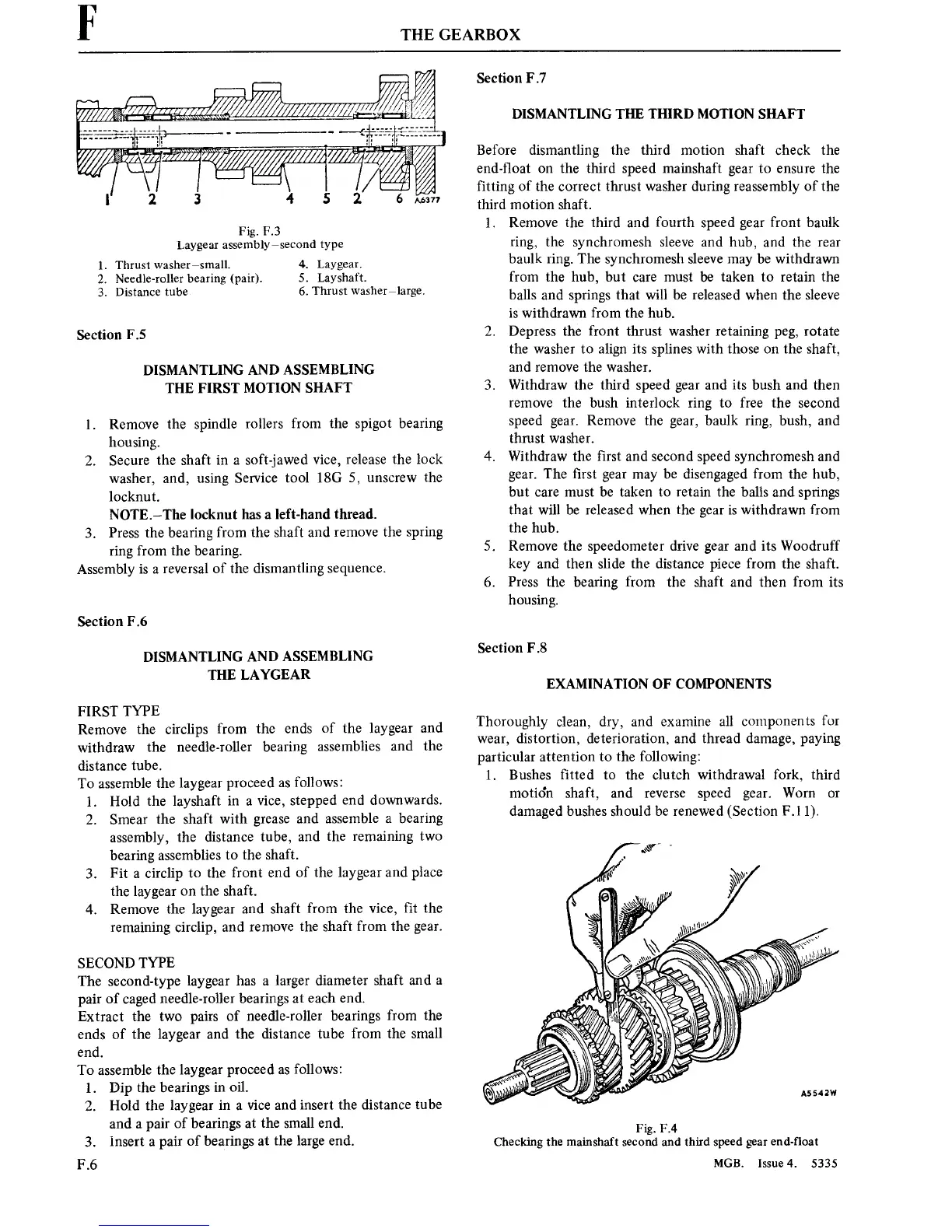

Fig.

F.4

Checking the mainshaft

secondand

third speed

gear

end-float

MGB.

Issue4.

5335

Loading...

Loading...