A

THE

ENGINE

“

\

lIHllllHllllllllllllllllll

“Ill

5

m

utm/I/m/

g

:::::::::mun

ML/

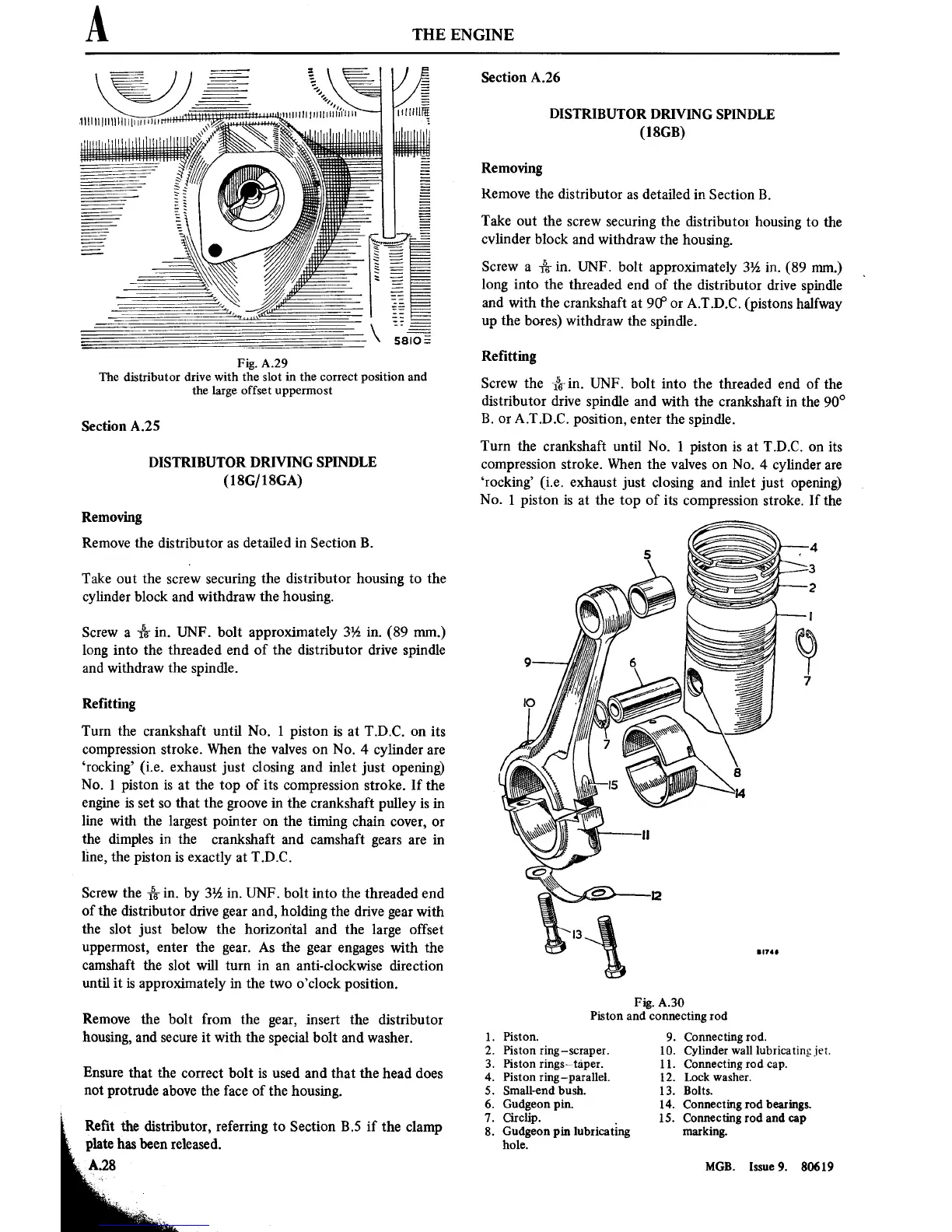

Fig. A.29

The distributor

drive with the

slot

in the

correct

position and

the large

offset

uppermost

Section A.25

DISTRIBUTOR DRIVING

SPINDLE

(18G/18GA)

Removing

Remove

the distributor

as

detailed

in Section B.

Take

out

the

screw

securing

the distributor housing

to

the

cylinder block and withdraw

the housing.

Screw

a

'158‘i11.

UNF.

bolt approximately 3%

in.

(89 mm.)

long

into

the threaded

end

of the distributor drive spindle

and withdraw the spindle.

Re■tting

Turn

the crankshaft until No.

1 piston is

at

T.D.C.

on

its

compression

stroke. When the

valves

on

No.

4

cylinder

are

‘rocking’

(i.e.

exhaust

just

closing and inlet

just

opening)

No.

1 piston

is

at

the

top

of

its

compression

stroke. 1f the

engine is

set

so

that the

groove

in

the crankshaft

pulley

is in

line with the

largest

pointer

on

the

timing

chain

cover, or

the dimples

in

the crankshaft and camshaft

gears are

in

line,

the

piston is

exactly

at

T.D.C.

Screw

the

%

in.

by 3%

in.

UNF. bolt

into

the threaded

end

of

the distributor

drive

gear

and,

holding

the

drive

gear

with

the slot

just below

the

horizontal and the

large

offset

uppermost, enter

the

gear.

As

the

gear engages

with the

camshaft

the slot

will

turn

in

an

anti-clockwise

direction

until

it

is

approximately

in

the

two

o’clock

position.

Remove the bolt from

the

gear,

insert

the

distributor

housing,

and

secure

it

with the special bolt

and washer.

Ensure

that the

correct

bolt

is

used

and

that the

head does

not

protrude above the

face of the housing.

Re■t

the

distributor, referring

to

Section B.5

if

the clamp

plate has

been

released.

3

A.28

Section

A.26

DISTRIBUTOR

DRIVING SPINDLE

(180B)

Removing

Remove the distributor

as

detailed

in Section B.

Take

out

the

screw

securing

the distributor

housing

to

the

cvlinder

block

and withdraw the housing.

Screw

a

%

in.

UNF. bolt

approximately 31/;

in.

(89 mm.)

long

into

the threaded

end of the distributor

drive spindle

and with the

crankshaft

at

90°

or

A.T.D.C.

(pistons

halfway

up

the bores)

withdraw

the spindle.

Refitting

Screw

the

T'Sg'

in.

UNF. bolt

into

the threaded

end

of

the

distributor

drive

spindle and with the

crankshaft

in

the

90°

B.

or

A.T.D.C.

position,

enter

the spindle.

Turn the crankshaft

until

N0.

1 piston is

at

T.D.C.

on

its

compression

stroke. When the valves

on

No.

4

cylinder

are

‘rocking’

(i.e.

exhaust

just

closing

and inlet

just

opening)

No.

1 piston is

at

the

top

of

its

compression

stroke.

If

the

W.

\\\\\\\\

\\

/

In“

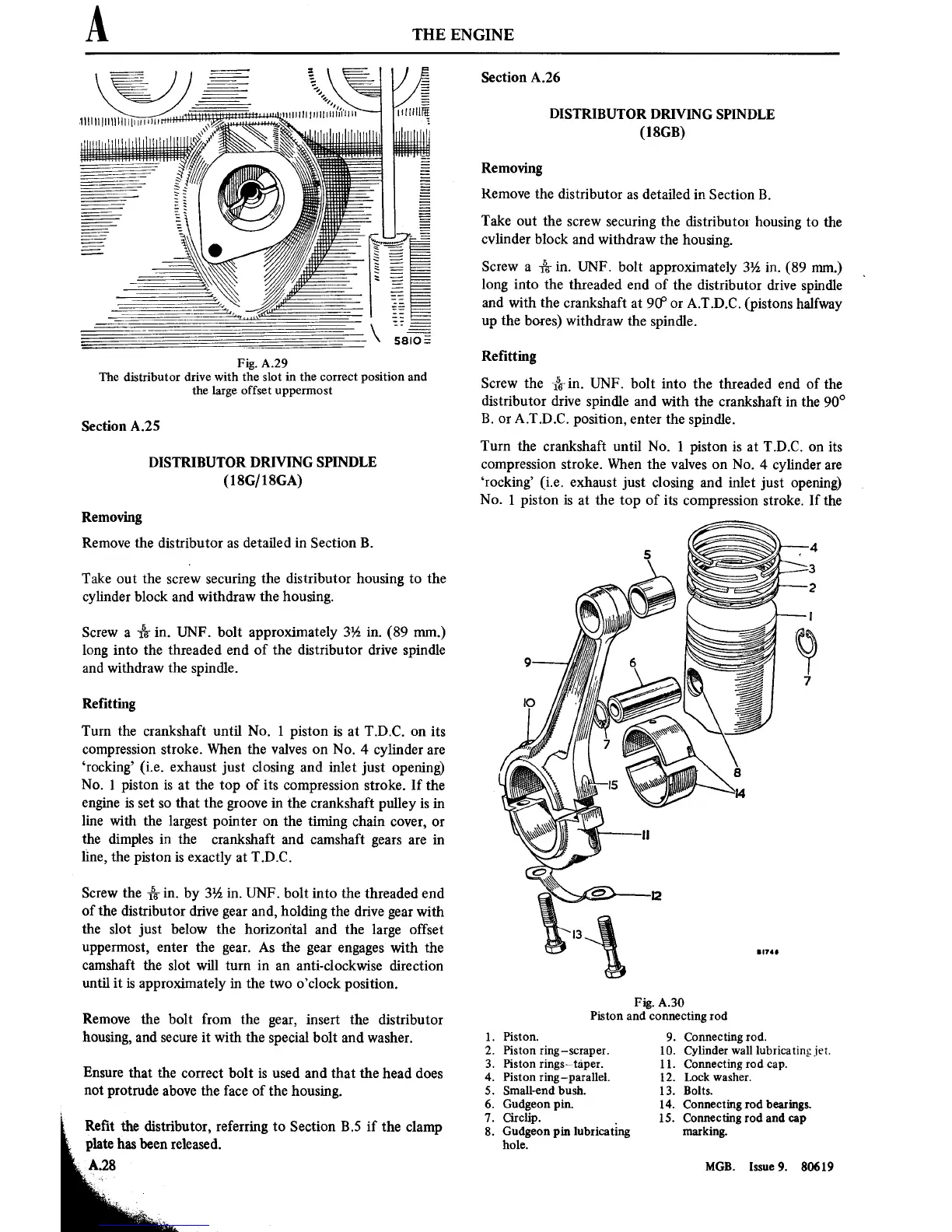

Fig.

A.30

Piston and

connecting rod

1.

Piston.

9.

Connectingrod.

2. Piston ring—scraper. 10. Cylinder wall lubricating jet.

3. Piston rings~taper.

ll.

Connectingrod

cap.

4. Piston ring—parallel. 12. Lock washer.

5.

Small~endbush.

l3. Bolts.

6.

Gudgeon

pin. 14.

Connecting

rod

bearings.

7.

Circlip.

,

15. Connecting

rod and

cap

8.

Gudgeon

pin lubricating marking.

hole.

MGB.

Issue

9. 80619

Loading...

Loading...