THE

ENGINE

Lubricate

the

main

bearing cap

joint seal

liberally

with oil

before

re■tting. When re■tting the bearing

caps

on

early

engines

use a

new

locking plate

to

lock the

nuts;

on

later

engines

check

that the self-locking

nuts

lock

to

the stud

threads ef■ciently. Tighten the bearing

cap

nuts to

the

torque

■gure

given

in

‘GENERAL

DATA’.

Section

A.14

PISTONS AND

CONNECTING

RODS

Remove

the cylinder

head

as

in

Section

A.6. Drain

and

remove

the

sump

and

oil strainer

as

in

Section

A.1

l.

The

pistons

and

connecting

rods

must

be

withdrawn

from

the

top

of the

cylinder block.

Unlock and

remove

the

big-end

bolts

and

remove

the

bearing

caps.

Release

the

connecting

rod

from the

crankshaft.

Withdraw the

piston

and

connecting

rod from the

top

of

the cylinder

block and

refit the

bearing

cap.

The big-end

bearing

caps are

offset. When

used

parts

are

replaced after

dismantling

it is

essential

that they should

be

■tted

in

their

original

positions.

In

order

to

ensure

this, mark the

caps

and

connecting

rods

on

their sides which

are

■tted together

with the number of the cylinder from

which each

was

taken.

Replacement

of the

piston

and

connecting

rod

is

a

direct

reversal

of the

above,

but the

piston

ring

gaps

should

be

set

at

90°‘to

each other.

It

is

essential

that the

connecting

rod and

piston

assemblies

should be

replaced

in

their

own

bores and

■tted

the

same

way

round,

i.e.

with the

gudgeon

pin

clamp

screw on

the

camshaft

side

of the

engine.

The

piston

crowns are

marked

‘FRONT’

to

assist

correct

assembly

to

the

connecting

rods.

Re■t the big-end

bearings

in

their original

positions.

Pistons

and

gudgeon

pins

(18G/18GA)

The gudgeon

pin is

rigidly held

in

the split little-end

of

the

connecting

rod by

a

clamp bolt

engaging

the central

groove

of

the gudgeon

pin.

AD1381

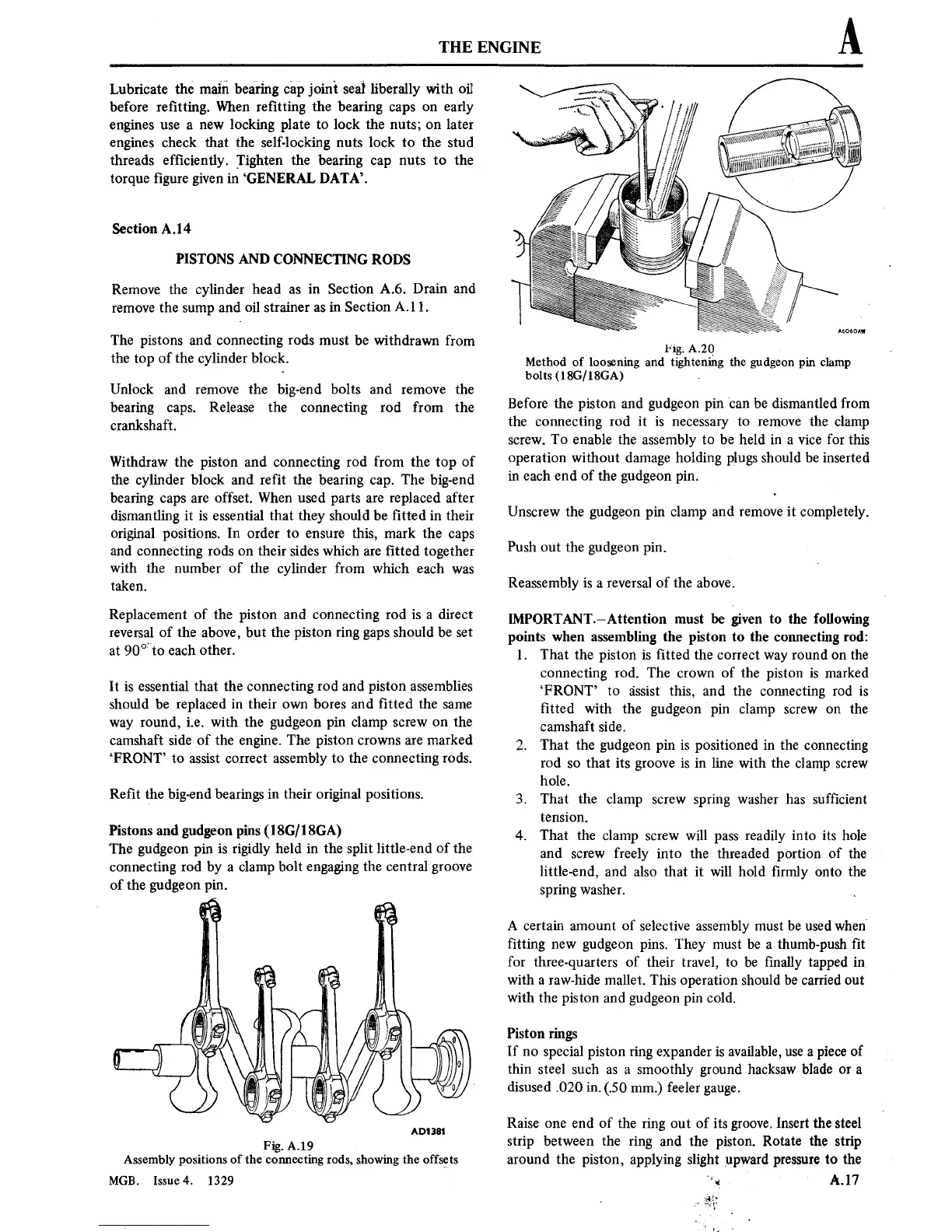

Fig.

A.19

Assembly positions of the connecting rods, showing the offsets

1329MGB.

Issue

4.

%<

i

’47/l/

/

//’///////

/////

4%

A5060A‘

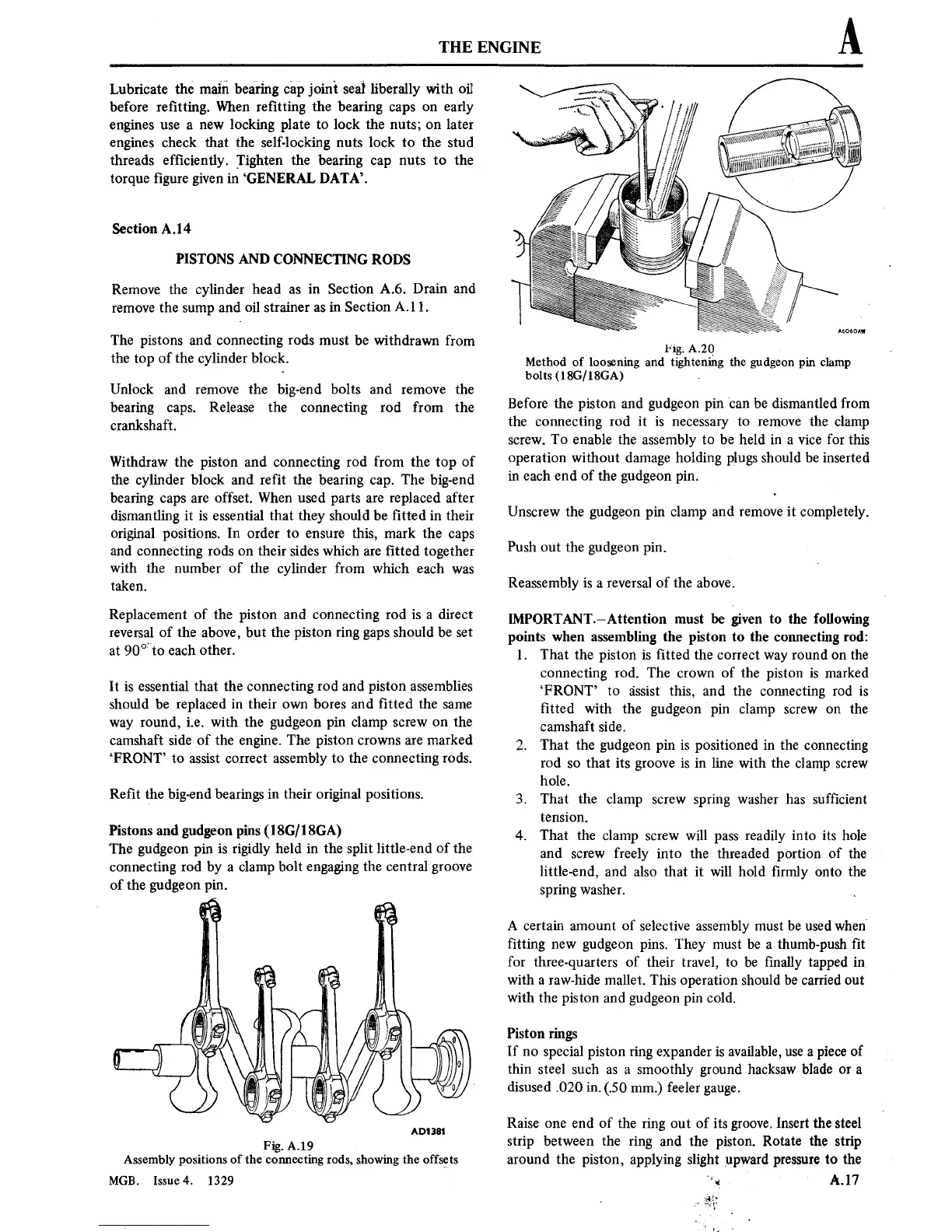

Fig.

A20

Method of loosening and tightening the

gudgeonpin clamp

bolts

(18G/18GA)

.

Before the

piston

and

gudgeon

pin

can

be

dismantled

from

the

connecting

rod

it is

necessary

to

remove

the clamp

screw.

To

enable the assembly

to

be held

in

a

vice

for this

operation

without damage holding plugs should

be inserted

in

each

end

of the gudgeon

pin.

Unscrew the gudgeon

pin

clamp and

remove

it

completely.

Push

out

the gudgeon

pin.

Reassembly

is

a

reversal

of

the above.

IMPORTANT—Attention

must

be given

to

the

following

points when assembling the

piston

to

the

connecting

rod:

1.

That the

piston is

■tted

the

correct

way

round

on

the

connecting

rod. The

crown

of the

piston is

marked

‘FRONT’

to

assist

this,

and the

connecting

rod

is

■tted

with the gudgeon

pin

clamp

screw on

the

camshaft

side.

2.

That

the gudgeon

pin is

positioned

in

the

connecting

rod

so

that

its

groove

is in

line with the

clamp

screw

hole.

3.

That the clamp

screw

spring

washer

has

suf■cient

tension.

4.

That the

clamp

screw

will

pass

readily

into its

hole

and

screw

freely

into

the threaded

portion

of

the

little-end,

and also

that

it

will hold

■rmly

onto

the

spring

washer.

A certain

amount

of

selective assembly

must

be used

when

■tting

new

gudgeon

pins.

They

must

be

a

thumb-push

■t

for three-quarters of their

travel,

to

be

■nally

tapped

in,

with

a

raw-hide mallet.

This

operation

should be carried

out

with the

piston

and gudgeon

pin

cold.

Piston rings

If

no

special

piston

ring

expander

is

available,

use a

piece

of

thin

steel

such

as

a

smoothly ground hacksaw

blade

or a

disused

.020

in.

(.50 mm.) feeler

gauge.

Raise

one

end

of the

ring

out

of

its

groove.

Insert

the

steel

strip

between the

ring

and

the

piston.

Rotate

the

strip

around the

piston,

applying

slight upward

pressure

to

the

"a

'

A.l7

at,

r

*3:

r

y

Loading...

Loading...