B

THE

IGNITION SYSTEM

Section

B.l4

LOCATING A

LOW-TENSION CIRCUIT FAULT

Having

determined, by

testing

as

previously

described, that

the

fault lies

in

the low-tension circuit,

switch

on

the

ignition,

and

turn

the

engine

until the

contact

breaker

points

are

fully opened.

Refer

to

the

wiring

diagram

and check the

circuit

with

a

voltmeter

(0-20

volts)

as

follows.

NOTE—If the circuit is in

order,

the reading

on

the

voltmeter

should be

approximately 12

volts.

1. Battery

to

control box

terminal ‘B’. Connect

a

voltmeter between

control box

terminal

‘B’

and earth.

No reading

indicates

a

damaged cable

or

loose

connections.

Control box

terminal

‘B’

to

ignition

switch terminal

(brown lead). Connect

a

voltmeter between

the

ignition

terminal

and

earth. No

reading

indicates

a

damaged cable

or

loose connections.

Ignition

switch (white

lead). Connect

a

voltmeter

between

the the

ignition

switch terminal and earth.

Turn

the

ignition

key

to

the

ignition

position.

No

reading indicates

a

fault

in

the

ignition

switch.

Ignition

switch (white

with red

lead).

Connect

a

voltmeter

between

the

ignition

switch terminal and

earth.

Turn

the

ignition

key

to

the

start

position.

No

reading

indicates

a

fault

in

the

ignition

switch.

'

Ignition

switch

to

fusebox terminal “A3’ (white lead).

Connect

a

voltmeter

between the

fuse

unit

terminal

‘A’

and earth. N0

reading indicates

a

damaged

cable

or

loose

connections.

Fusebox

terminal

‘A3’

to

ignition coil

terminal

‘SW’.

Connect

a

voltmeter

to

the

ignition

coil

terminal

‘SW’

and

to

earth. No reading

indicates

a

fault

in

the

primary

winding

of the coil

and

a

new

coil

must

be

fitted.

Section B.

1

5

SERVICING THE

DISTRIBUTOR—

Lucas

type

4SD4

liqu

Lubrication

1. Remove

the distributor

cover

and

rotor

arm.

2.

Lightly

smear

the

cam

and

pivot

post

with

grease.

3.

Add

a

few

drops

of

oil

to

the

felt

pad

in

the

top

of

the

cam

spindle.

4. Add

a

few

drops

of oil through the

gap

between the

cam

spindle

and

base

plate

to

lubricate the

centrifugal

weights.

5. Every 25,000

miles lubricate

the

contact

breaker

assembly

centre

bearing

with

a

drop

of oil

in

each of

,

the

two

holes

in

the base plate.

CAUTION:

Do

not

oil

the

cam

wiping pad.

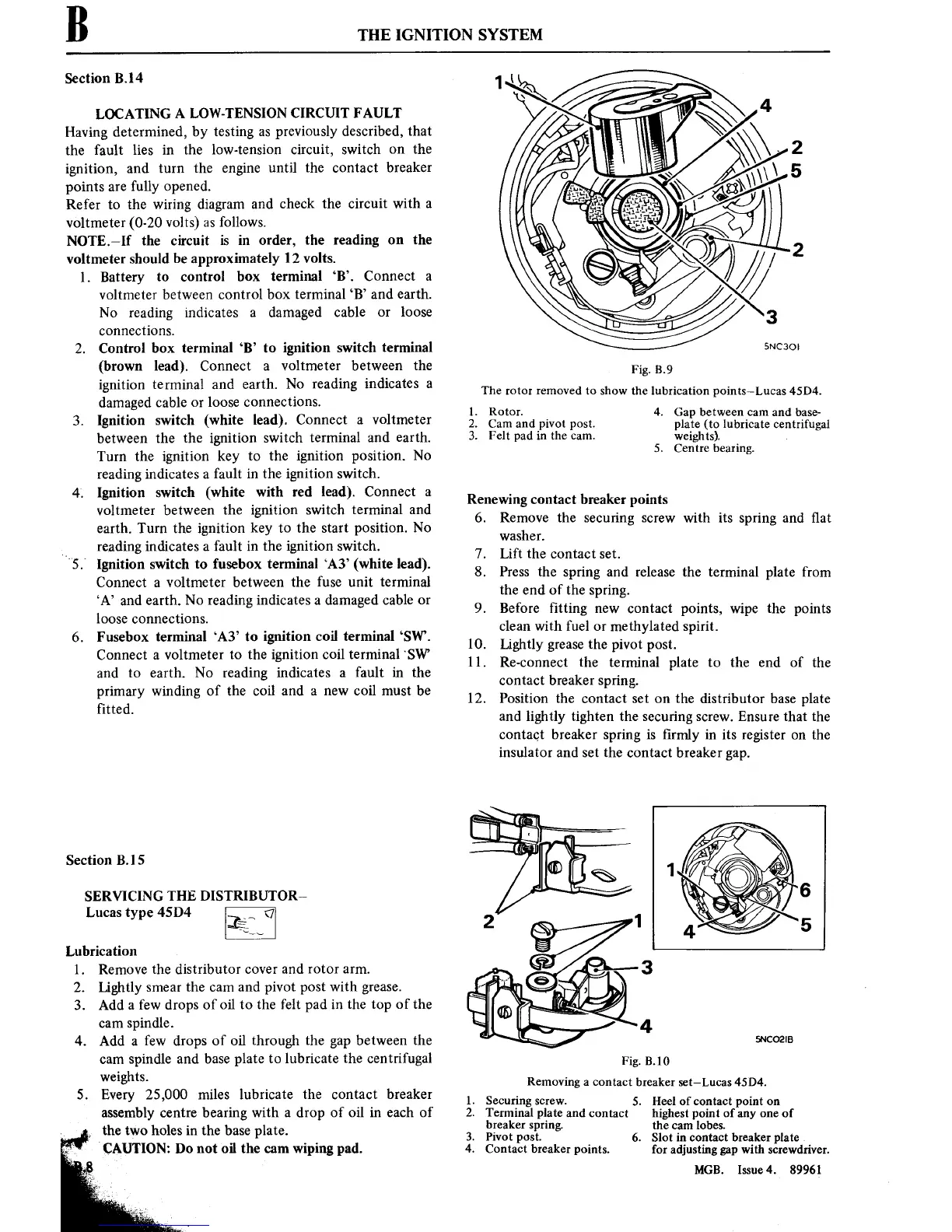

5NC30|

Fig. 3.9

The

rotor

removed

to

show the lubrication

points—Lucas45D4.

l.

2.

3.

Rotor.

4.

Cam

and pivot

post.

Felt pad in the

cam.

Gap between

cam

and base-

plate (to lubricate centrifugal

weights).

_

5. Centre bearing.

Renewing

contact

breaker

points

6.

7.

8.

9.

10.

11.

12.

PE”

59’."

Remove the

securing

screw

with

its spring and

■at

washer.

Lift the

contact set.

Press the

spring and

release the terminal plate

from

the

end

of the

spring.

Before ■tting

new

contact

points, wipe

the

points

clean with fuel

or

methylated

spirit.

Lightly

grease

the

pivot

post.

Re-connect the terminal plate

to

the end of

the

contact

breaker

spring.

Position the

contact set

on

the

distributor

base plate

and lightly tighten the

securing

screw.

Ensure that the

contact

breaker

spring is

■rmly

in its register

on

the

insulator

and

set

the

contact

breaker

gap.

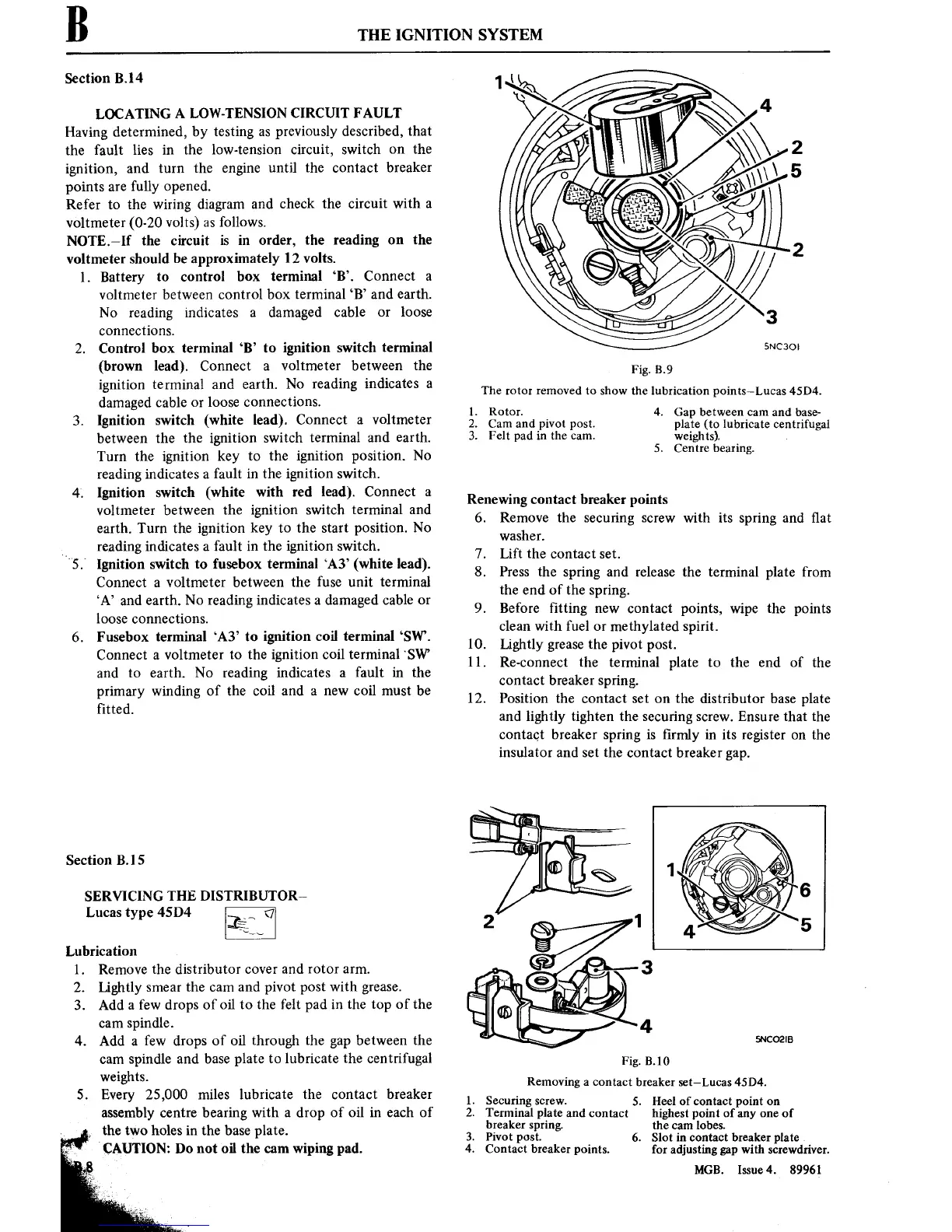

5NCO2IB

Fig.

3.10

Removing

a

contact

breaker

set—Lucas

45D4.

Securing

screw.

5.

Terminal plate

and

contact

breaker

spring.

Pivot

post. 6.

Contact breaker

points.

Heel

of

contact

point

on

highestpoint

of

any one

of

the

cam

lobes.

Slot

in

contact

breakerplate

for adjusting

gap

with screwdriver.

MGB.

Issue4. 89961

Loading...

Loading...