A

THE

ENGINE

Unscrew

and

remove

the

two

securing

screws

and

then

remove

the

tensioner

and

its

backplate.

Unlock

and

remove

the

camshaft

chain wheel

nut

and

remove

the

nut

and

lock washer. Note that

the locating

tag

on

the lock

washer

■ts

into

the keyway

of

the

camshaft

chain wheel.

The

camshaft and

crankshaft chain wheels

may now

be

removed,

together

with the

timing

chain, by

easing

each

wheel

forward,

a

fraction

at

a

time,

with suitable smaller

levers.

As

the

crankshaft

gear

wheel

is

withdrawn

care

must

be

taken

not to

lose

the

gear

packing washers

immediately

behind

it.

When reassembling

replace the

same

number

of

washers

as was

found when dismantling,

unless

new

camshaft

or

crankshaft

components

have

been

■tted which

will disturb the

alignments

of the

two

gear

wheels.

To

determine the thickness

of washers required place

a

straight

edge

across

the

sides

of the

camshaft wheel teeth

and

measure

with

a

feeler

gauge the

gap

between

the

straight-edge and the

crankshaft

gear.

Subtract .005

in.

(~13

mm.)

from the feeler

gauge

reading and add

the resultant

thickness of crankshaft

gear

packing washers.

When replacing the

timing

chain and

gears,

set

the

crankshaft with

its

keyway

at

T.D.C., and the

camshaft

with

its

keyway approximately

at

the

one

o’clock

position

when

seen

from the

front.

Assemble

the

gears

into

the

timing

chain with

the

two

marks

on

the

gear

wheels

opposite

to

each other,

as

in

Fig. A.l

1.

Keeping the

gears

in

this

position,

engage

the

crankshaft

gearrkeyway

with the

key

on

the crankshaft and

rotate

the

camshaft

until the

camshaft

gear

keyway and key

are

aligned. Push the

gears

onto

the

shafts

as

far

as

they will

go

and

secure

the

camshaft

gear

with the lock washer and

nut.

Replace

the

oil

thrower, with the face marked

‘F’

or

the

concave

side

(early-type)

away

from the

engine,

and the

remaining

components.

=.

/

Z;

%

A4

866

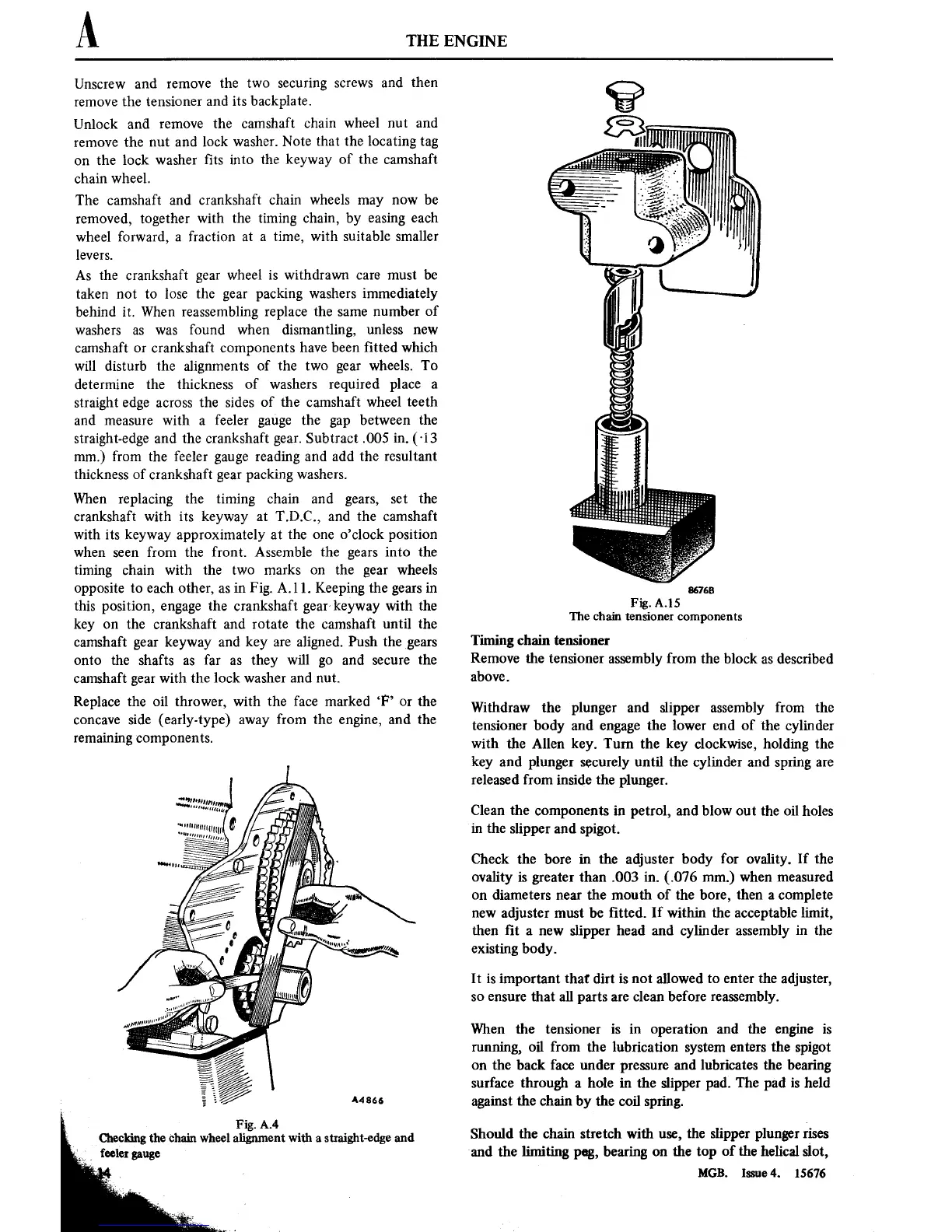

Fig. A.4

Checkingthe chain wheel alignment with

a

straightedge and

feeler

gauge

86768

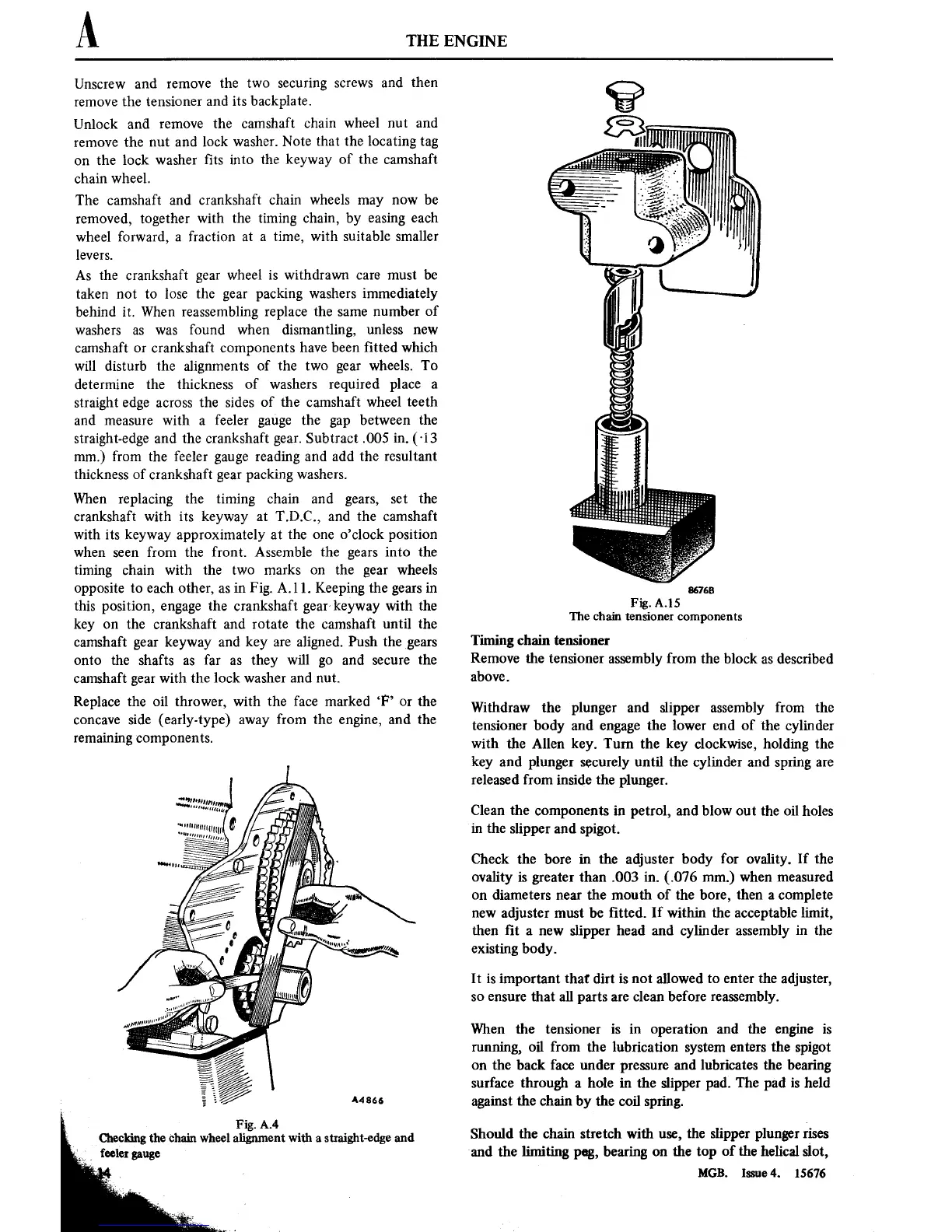

Fig. A.15

The chain

tensioner

components

Timing

chain

tensioner

Remove

the

tensioner

assembly from the

block

as

described

above.

Withdraw the

plunger and slipper assembly

from

the

tensioner

body and

engage

the lower

end

of

the cylinder

with the

Allen key. Turn

the

key clockwise, holding the

key

and plunger securely until

the

cylinder and

spring

are

released from

inside

the

plunger.

Clean the

components

in

petrol, and blow

out

the oil holes

in

the

slipper and

spigot.

Check the bore

in

the adjuster body

for

ovality.

If the

ovality

is

greater

than

.003

in.

(.076 mm.) when measured

on

diameters

near

the mouth of the bore,

then

a

complete

new

adjuster

must

be

■tted.

If

within the acceptable limit,

then ■t

a new

slipper head and cylinder

assembly

in

the

existing

body.

It

is important

that dirt

is

not

allowed

to

enter

the adjuster,

so ensure

that all

parts

are

clean

before reassembly.

When

the

tensioner is in operation

and the

engine is

running,

oil from the lubrication

system enters

the

spigot

on

the back face under

pressure

and lubricates

the

bearing

surface through

a

hole

in

the slipper

pad. The pad

is

held

against

the

chain by the coil

spring.

Should

the chain stretch with

use,

the slipper plunger

rises

and the limiting

peg,

bearing

on

the

top

of the

helical slot,

MGB. lssue4.

15676

Loading...

Loading...