THE

BO

DY

R

Unscrew the

four

screws

securing

the hinge

bracket

to

the

body

and

remove

the hinge and bracket

assembly.

Refitting

Re■tting

is

a

reversal

of

the removal

sequence,

but before

finally

tightening

the hinge leaf

screws ensure

that

the

door

lock

engages

correctly

and

that

the door

is correctly

positioned with the

body.

Section R.19

WINDSCREEN

AND BACK-LIGHT GLASSES

(GT)

Removing

Lift the windscreen

wiper

arms

clear

of the

glass.

Remove

the

■nisher strip.

Prise

up

the end

of

the locking filler

and carefully pull

it

from the

channel

in

the surround rubber.

'

Press the glass from

inside

the

car,

commencing

at

a corner,

and

ease

the

surround rubber

from

the metal edge of

the

body

aperture.

Refitting

If

the glass has been broken,

remove

any

pieces

which

remain in

the channel. Examine

the rubber, and

use

a new

rubber should there be

any

signs

of

damage

or

deterioration.

Fit the surround rubber

to

the body

aperture

and

lubricate

the ‘glass’

channel with

a

soap-and-water

solution.

Place

the glass

into

the

lower channel of the

rubber

surround and

commence

at

the

corner

to

lift the lip

of

the

rubber

over

the

glass,

using

Service tool ISO 468. Use

the

short

peg

on

the handle of the installation tool for this

purpose.

Apply

a

soap-and-water solution

to

the

locking

filler

strip

channel

to

assist in

■tting the

strip.

Using Service tool 18G 468

with

adaptor 18G 468

A,

thread

the

end of

the ■ller

strip

through the

eye

of the

adaptor and under the roller.

Lay

the ■ller

strip

in

position

/

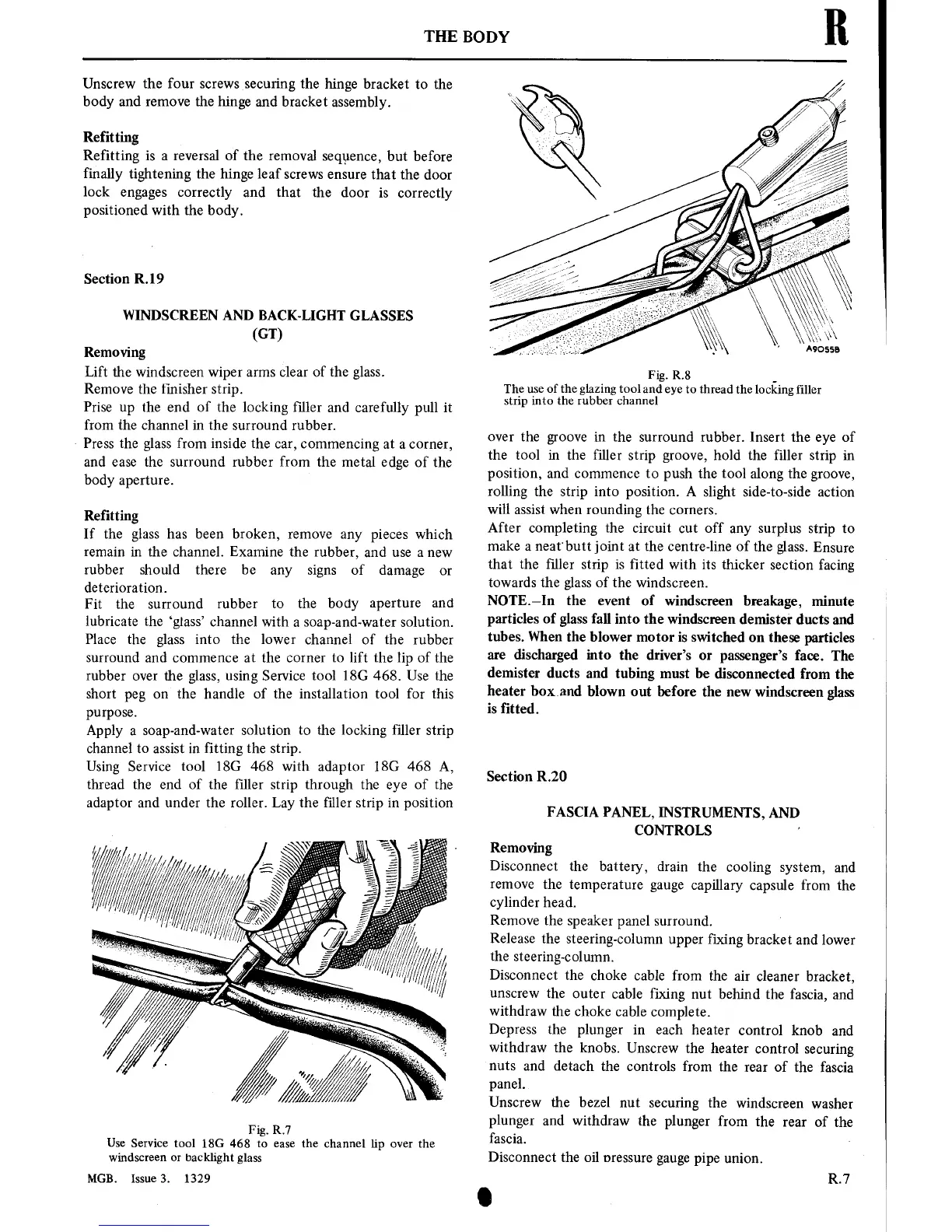

Fig. R.

Use

Service tool 18G

468

to

ease

the

channel

lip

over

the

windscreen

or

backlight

glass

MGB.

Issue3.

1329

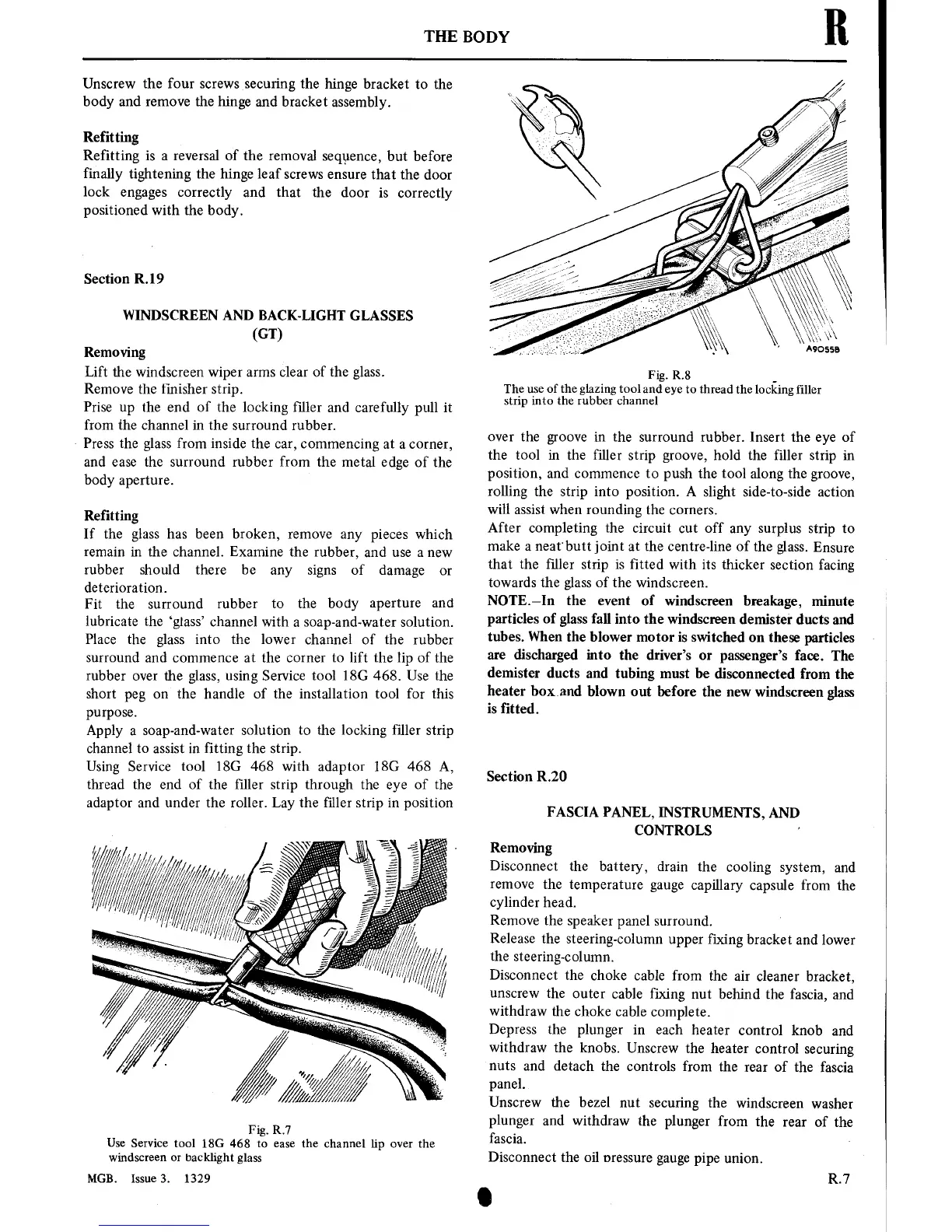

A9OSSB

Fig. R8

The

use

of the glazing

tool and

eye

to

thread

the

locking

■ller

strip into the rubber channel

over

the

groove

in

the

surround rubber.

Insert

the

eye

of

the tool

in

the filler

strip

groove,

hold the filler

strip in

position,

and

commence

to

push the

tool along the

groove,

rolling the

strip into position.

A

slight

side-to-side

action

will

assist

when rounding the

corners.

After completing the

circuit

cut

off

any

surplus

strip

to

make

a

neat'butt

joint

at

the centre-line of the

glass.

Ensure

that the ■ller

strip

is

fitted

with

its

thicker

section

facing

towards the

glass

of

the windscreen.

NOTE—In

the

event

of windscreen

breakage,

minute

particles

of

glass fall

into

the

windscreen demister ducts

and

tubes. When the

blower

motor

is

switched

on

these particles

are

discharged

into

the driver’s

or

passenger’s

face.

The

demister

ducts and

tubing

must

be disconnected

from the

heater

boxand

blown

out

before the

new

windscreen

glass

is

fitted.

Section R.20

FASCIA

PANEL,

INSTRUMENTS,

AND

CONTROLS

’

Removing

Disconnect

the battery,

drain the

cooling

system,

and

remove

the

temperature

gauge

capillary

capsule from the

cylinder head.

Remove the speaker

panel

surround.

Release the

steering-column

upper

fixing

bracket

and lower

the

steering-column.

Disconnect

the choke

cable from the

air

cleaner

bracket,

unscrew

the

outer

cable fixing

nut

behind the fascia,

and

withdraw

the choke

cable

complete.

Depress the plunger

in

each heater

control knob

and

withdraw

the

knobs. Unscrew the heater

control

securing

nuts

and detach

the controls from

the

rear

of

the fascia

panel.

Unscrew the bezel

nut

securing

the

windscreen

washer

plunger

and withdraw

the plunger

from

the

rear

of

the

fascia.

Disconnect the oil

pressure

gauge

pipe

union.

R.7

Loading...

Loading...