THE GEARBOX

F

Third

motion

shaft bushes

Heat

the

bushes

to

between 180

and

200°

C.

(356

and

392°

F.),

ensure

that the locating

tongues

on

the bushes

are

in

line

with the splines

on

the

shaft and that the oil holes

are

in

line, then assemble

the second-speed

bush,

interlock

washer, and third speed

bush.

Section

F .12

FITTING THE GEARBOX FRONT COVER

To

prevent

oil leaking

past

the

gearbox

front

cover

oil seal

the

cover

must

be correctly

fitted

to

ensure

that the seal

is

concentric

with

the ■rst

motion

shaft.

When

refitting

the

cover

proceed

as

follows.

Clean

off the

cover

and

examine it

carefully

for burrs and

bruising,

particularly around

the

bore, stud

holes,

and

machined surfaces. Check the

■at surfaces for

twist

and

warp,

and

correct

it

if

necessary.

If the condition

is

too

bad

to

correct,

■t

a

new cover.

Remove

and discard the front

cover

to

gearbox gasket and

clean

off the ■at surfaces around the base of all studs.

Offer

the

front

cover

(less oil

seal)

to

the

gearbox and push

it

fully home

on

the studs.

The

cover

should be

free

to

move

in

all directions, and

points

at

which the holes

may

be

binding

on

the studs

must

be

relieved until the

cover

is

free

to

.‘■oat’.

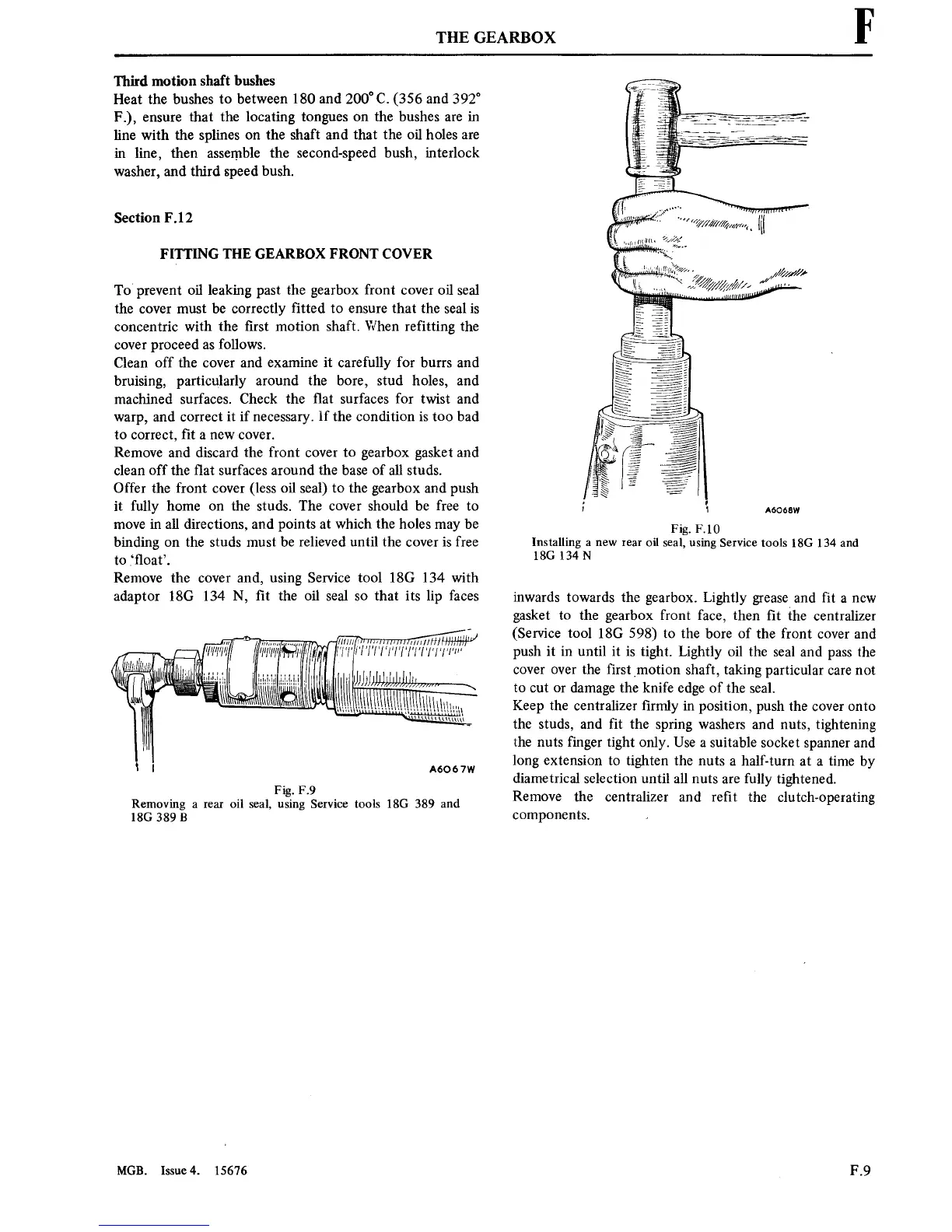

Remove

the

cover

and,

using

Service

tool 18G

134

with

adaptor 18G 134 N,

■t the oil seal

so

that

its

lip

faces

i

|

A6067W

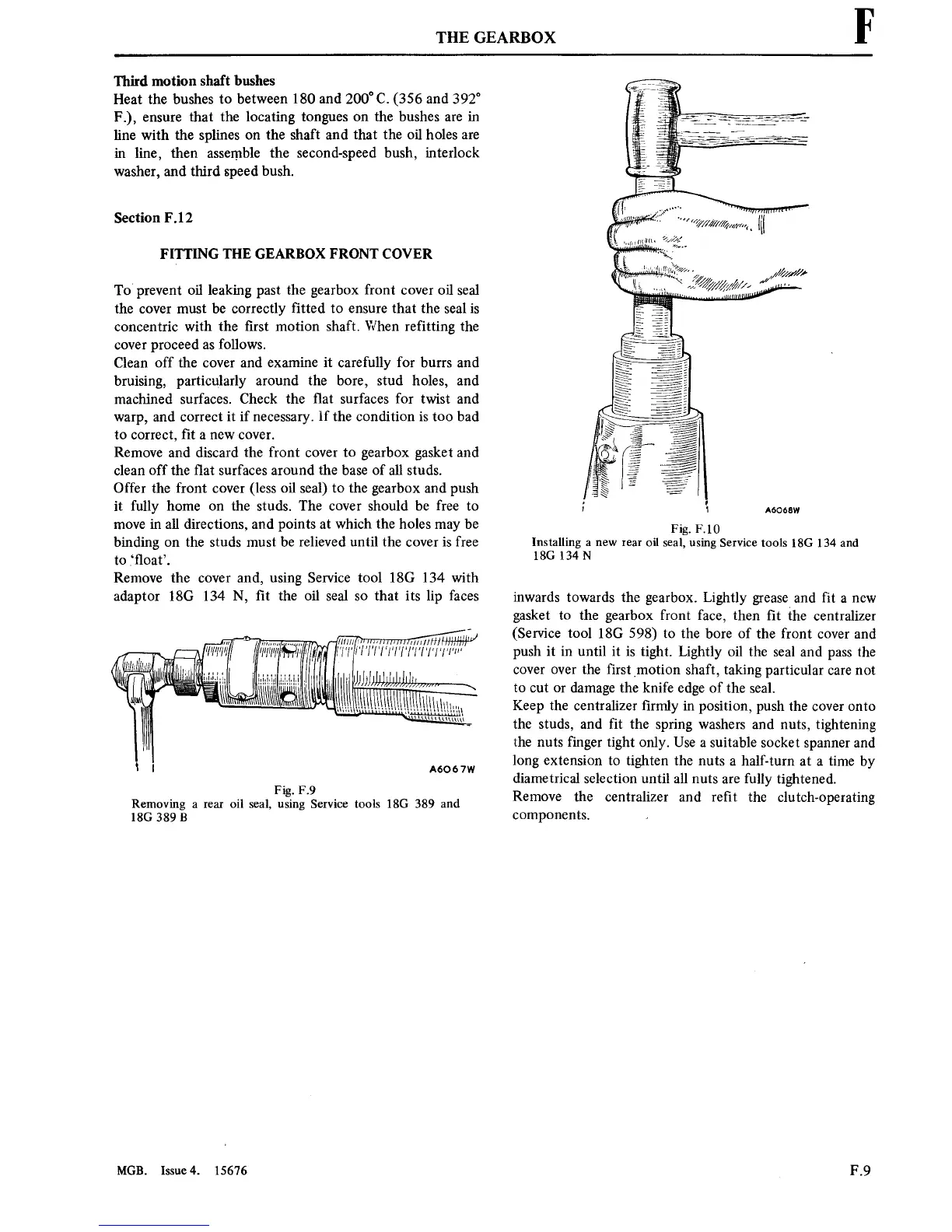

Fig. F.9

Removing

a

rear

oil seal, using Service tools

18G

389

and

18G

389

B

MGB. Issue4. 15676

ml

ff”;

//////////

“’\

,;////////////,/,//,

’/

"

A6068W

Fig.

F.10

Installing

a

new rear

oil seal,

using Servicetools 18G 134

and

18G

134

N

inwards

towards the

gearbox. Lightly

grease

and

fit

a new

gasket

to

the

gearbox front face,

then ■t

the

centralizer

(Service

tool

18G 598)

to

the

bore

of

the

front

cover

and

push

it in

until

it is

tight. Lightly

oil

the

seal and

pass

the

cover over

the first

motion

shaft,

taking particular

care

not

to

cut

or

damage

the

knife

edge

of the

seal.

Keep

the

centralizer ■rmly

in position,

push the

cover

onto

the

studs, and

■t

the

spring

washers

and

nuts,

tightening

the

nuts

finger

tight

only. Use

a

suitable

socket

spanner

and

long

extension

to

tighten the

nuts

a

half-turn

at

a

time

by

diametrical

selection

until

all

nuts

are

fully

tightened.

Remove the

centralizer

and

re■t

the clutch-operating

components.

F.9

Loading...

Loading...