A

THE ENGINE

Refitting the

cylinder head

Make

sure

that

the surfaces

of

both the cylinder

head and

the cylinder block

are

clean.

It will be noticed that the

cylinder

head gasket

is

marked ‘FRONT’

and ‘TOP’

to

assist

in

replacing

it

correctly

with the

copper

side

uppermost.

Having slipped the gasket

over

the

studs,

next

lower'the

cylinder head

into position.

Replace

the

vacuum

control

pipe

clip

and

fit the

seven

cylinder head external

nuts

■nger

tight.

Replace the push-rods

in

the

positions

from which they

were

taken.

Replace

the rocker assembly

and

securing

nuts

■nger tight. Tighten the

1]

cylinder head

nuts,

a

turn at

a

time, in

the order

given in

Fig.

A.2.

Finally,

tighten

the

four rocker

assembly

nuts.

Reassembly

continues in

the

reverse

order

to

the

dismantling procedure.

Switch

on

the

ignition

and check the fuel

system

for leaks.

Start

the

engine

and

run

it until

the

normal working

temperature

is

reached.

Remove the rocker

cover

and check

the valve

clearances

(see

Section

A.7).

Replace the

rocker

cover

and

connect

the breather hose.

Section A.7

VALVE GEAR AND VALVES

Removing

and

replacing

valves

Remove the

cylinder head

as

in

Section A.6.

Remove

the valve circlip.

Compress

the

double valve

springs, using

Service tool 18G45, and

remove

the

two

valve

cotters.

Release

the

valve

springs

and

remove

the

compressor,

valve

spring

cap,

shroud

(early

engines

only),

inner

and

outer

springs,

and

bottom

collar.

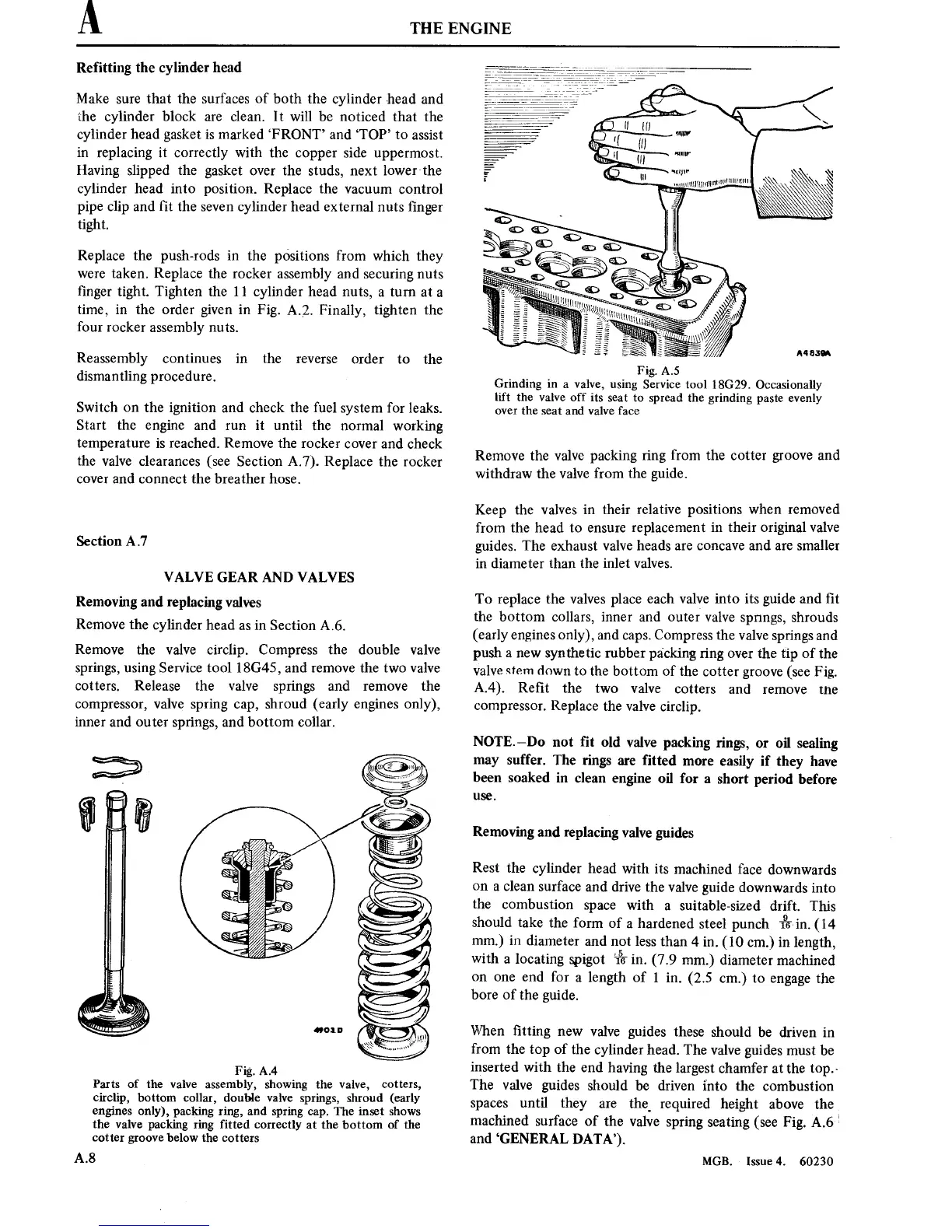

Fig. A.4

Parts

of

the valve assembly, showing

the valve,

cotters,

circlip, bottom collar, double

valve springs, shroud (early

engines only),

packing ring, and

spring

cap.

The inset

shows

the

valve

packing

ring fitted

correctly

at

the bottom

of the

cotter

groove

below the

cotters

A.8

Hutu!"

mmmmmmmmmllltII

Vlllll

\“

A483“

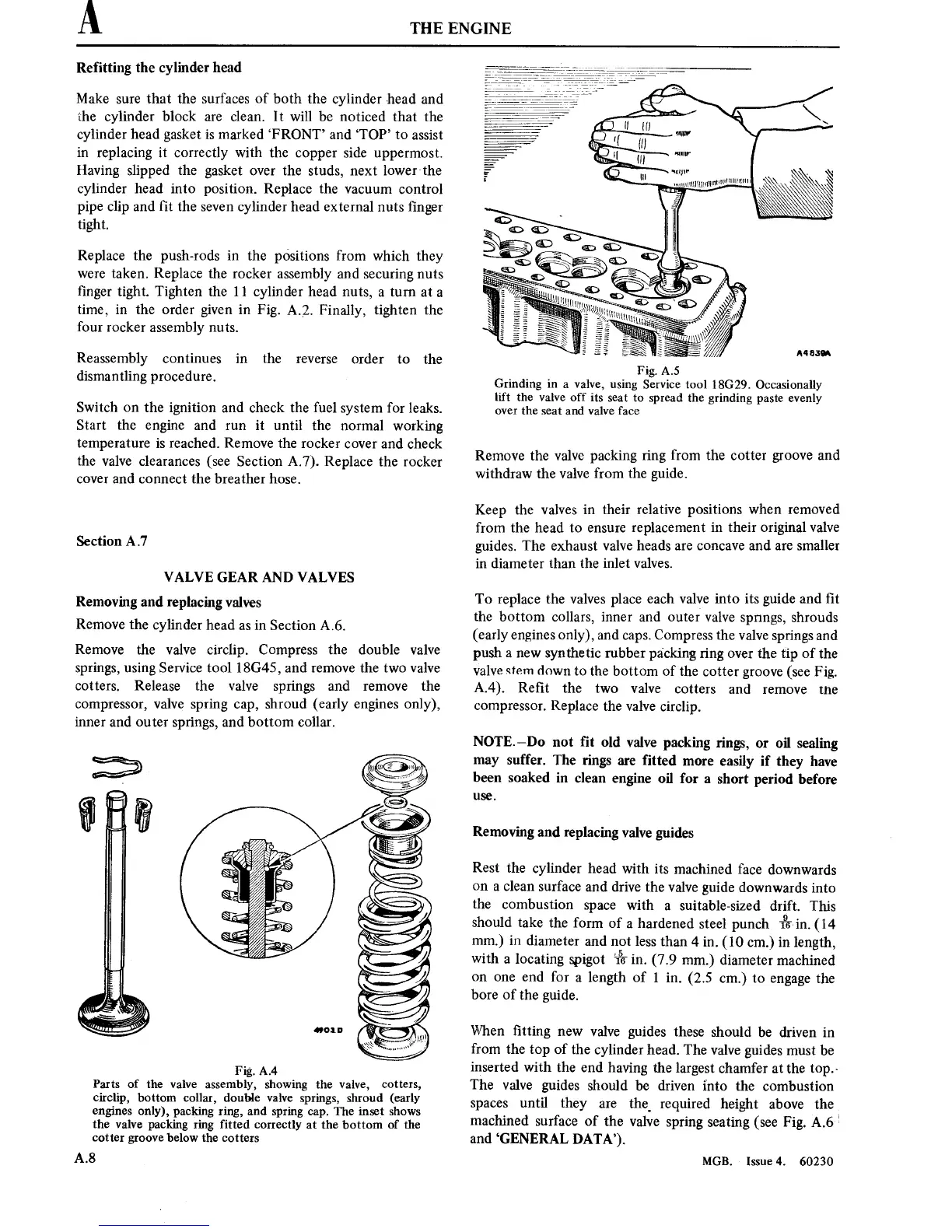

Fig.

A.5

Grinding

in

a

valve,

using Service

tool

18G29.

Occasionally

lift

the valve off

its

seat to

spread the

grinding

paste

evenly

over

the

seat

and

valve

face

Remove

the valve packing

ring

from the

cotter

groove

and

withdraw the valve

from the guide.

Keep the valves

in

their

relative

positions

when

removed

from the head

to

ensure

replacement

in

their original valve

guides. The

exhaust

valve

heads

are concave

and

are

smaller

in

diameter than the inlet

valves.

To

replace the valves place

each valve

into its

guide and ■t

the bottom

collars,

inner

and

outer

valve

springs,

shrouds

(early

engines

only),

and

caps.

Compress

the

valve

springs

and

push

a

new

synthetic

rubber packing

ring

over

the

tip

of

the

valve

stem

down

to

the bottom

of

the

cotter

groove

(see

Fig.

A.4).

Re■t the

two

valve

cotters

and

remove

the

compressor.

Replace

the valve

circlip.

NOTE—Do

not

fit

old valve

packing

rings,

or

oil sealing

may

suffer.

The

rings

are

fitted

more

easily if

they have

been soaked

in

clean

engine oil for

a

short

period before

use.

Removing and

replacing

valve guides

Rest the

cylinder

head

with

its

machined face

downwards

on

a

clean surface

and

drive the

valve guide

downwards

into

the

combustion

space

with

a

suitable-sized drift.

This

should

take the form

of

a

hardened

steel punch

T96

in.

(14

mm.)

in

diameter

and

not

less than

4

in.

(10 cm.)

in

length,

with

a

locating

spigot

%

in.

(7.9

mm.)

diameter machined

on one

end

for

a

length of

1 in.

(2.5

cm.)

to

engage

the

bore of the

guide.

When ■tting

new

valve

guides these

should be driven

in

from the

top

of the

cylinder head.

The

valve guides

must

be

inserted with the

end having

the largest chamfer

at

the

top.~

The

valve

guides should

be driven

into

the

combustion

spaces

until

they

are

the.

required height

above the

machined

surface

of the

valve

spring

seating

(see

Fig.

A.6r

and

‘GENERAL DATA’).

MGB. Issue4. 60230

Loading...

Loading...