I]

THE

STEERING GEAR

Section

I

.6

RACK AND

PINION

Dismantling

Hold

the rack

housing between

suitable clamps in

a

vice.

Remove

the

pinion

end

cover

and

joint

washer, placing

a

container

to

catch the oil

that

may

drain from

the housing.

Remove

the damper

cover

and shims,

exposing

the yoke,

damper

pad, and

spring.

After removal

of these the

pinion,

complete with ball

race

and

locknut

may

be

withdrawn.

Unlock the tie-rod

ball end locknuts and disconnect

the ball

end assemblies.

Release the rubber

gaiter

seal clips and

withdraw the seals.

Prise

up

the indentations

in

the

locking

rings

clear of the

slots

in

the rack and

ball housing. Slacken back the locking

ring

and

unscrew

the housing

to

release the tie-rod, ball

seat,

and

seat

tension

spring.

.

Withdraw the rack from the

pinion

end of the housing;

if

removed from the other end

the teeth

may

damage

the rack

housing bush.

To

remove

the rack housing bush

unscrew

the

self—tapping

screw

retaining it

and

carefully

drive

the

bush

out.

A5508W

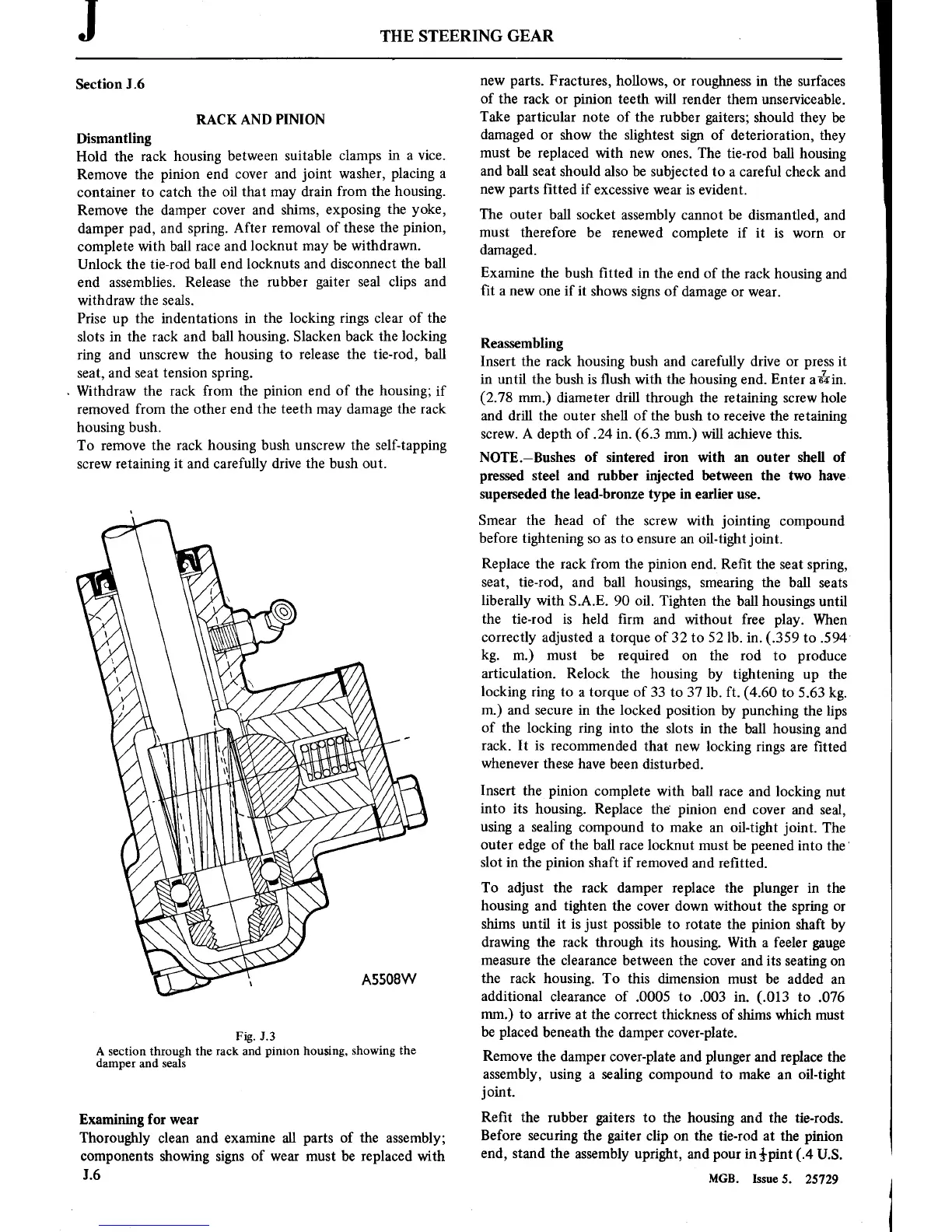

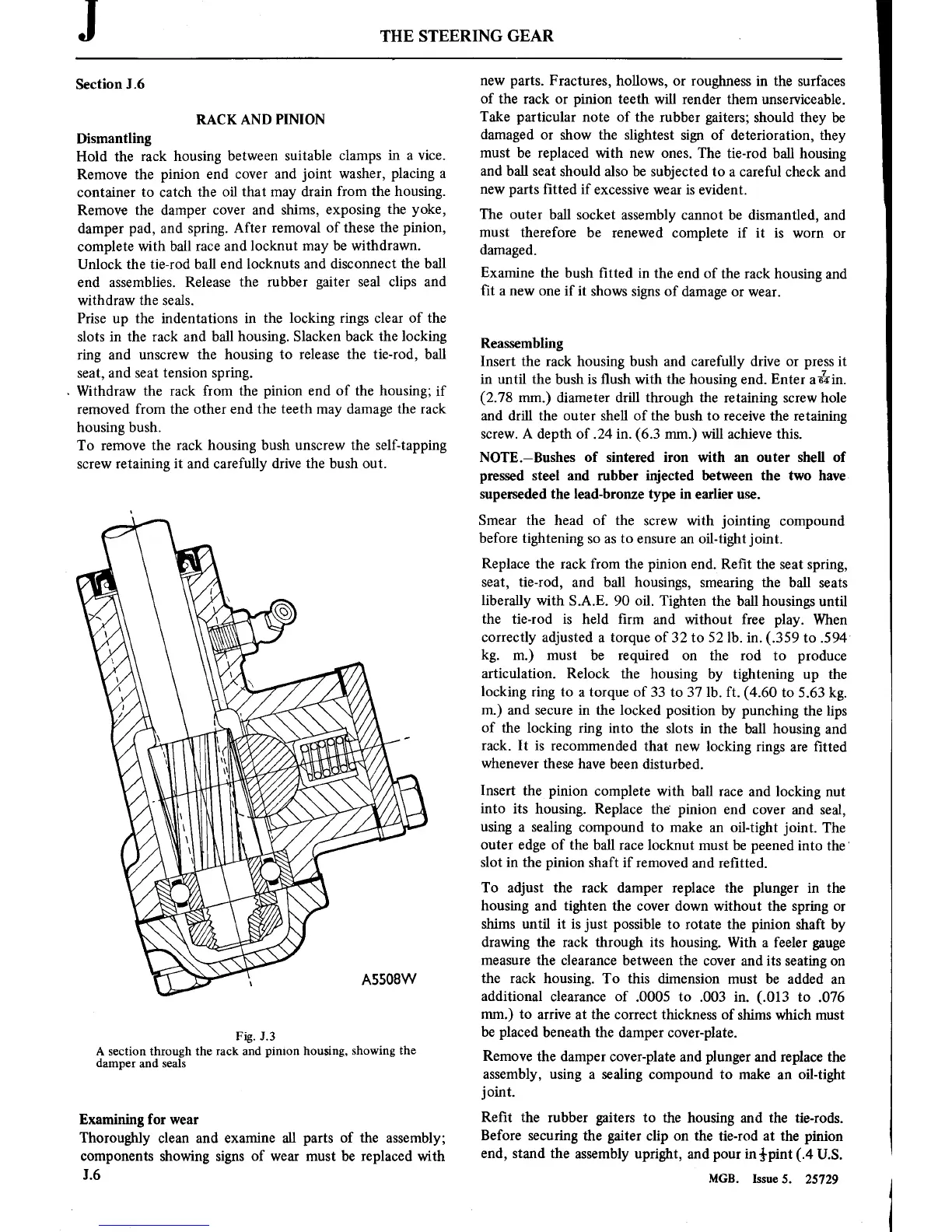

Fig. J.3

A

section through the

rack

and

pinion

housing, showing the

damper

and seals

Examining

for

wear

Thoroughly

clean and

examine

all

parts

of the

assembly;

components

showing

signs

of

wear

must

be replaced with

1.6

new

parts.

Fractures, hollows,

or

roughness

in

the surfaces

of the

rack

or

pinion

teeth will render them

unserviceable.

Take

particular

note

of the

rubber

gaiters;

should they

be

damaged

or

show the slightest

sign

of

deterioration, they

must

be replaced with

new ones.

The tie-rod ball housing

and

ball

seat

should

also be subjected

to

a

careful

check and

new

parts

■tted if

excessive

wear

is

evident.

The

outer

ball socket assembly

cannot

be dismantled, and

must

therefore

be renewed

complete if

it is

worn or

damaged.

Examine the

bush ■tted

in

the end of the

rack housing

and

■t

a new one

if

it

shows

signs

of

damage

or wear.

Reassembling

Insert

the

rack housing

bush

and

carefully

drive

or press

it

in

until the bush

is

flush with the housing end. Enter

again.

(2.78

mm.)

diameter drill through the

retaining

screw

hole

and drill the

outer

shell of the bush

to

receive

the

retaining

screw.

A

depth of

.24 in.

(6.3

mm.)

will achieve this.

NOTE—Bushes of

sintered

iron

with

an

outer

shell of

pressed steel and rubber injected between the

two

have,

superseded the lead-bronze

type

in

earlier

use.

Smear

the head

of the

screw

with

jointing compound

before

tightening

so as

to

ensure an

oil-tight

joint.

Replace the

rack

from the

pinion

end. Re■t the

seat

spring,

seat,

tie-rod, and ball housings,

smearing

the ball

seats

liberally

with S.A.E.

90

oil. Tighten

the ball housings

until

the tie-rod

is

held ■rm

and without free play.

When

correctly adjusted

a

torque

of

32

to

52

lb.

in.

(.359

to

.594'

kg.

m.)

must

be

required

on

the rod

to

produce

articulation.

Relock the housing

by tightening

up

the

locking

ring

to

a

torque

of

33

to

37

lb. ft.

(4.60

to

5.63 kg.

m.)

and

secure

in

the

locked

position

by

punching

the

lips

of the

locking

ring into

the slots

in

the

ball housing

and

rack.

It

is recommended

that

new

locking

rings

are

■tted

whenever

these have

been disturbed.

Insert

the

pinion

complete

with ball

race

and locking

nut

into its

housing.

Replace the‘

pinion

end

cover

and seal,

using

a

sealing compound

to

make

an

oil-tight

joint.

The

outer

edge of the ball

race

locknut

must

be peened

into

the’

slot

in

the

pinion

shaft if

removed and re■tted.

To

adjust the

rack damper replace the plunger

in

the

housing

and tighten the

cover

down without the

spring

or

shims

until

it is just

possible

to

rotate

the

pinion

shaft by

drawing the

rack through

its

housing.

With

a

feeler

gauge

measure

the clearance

between the

cover

and

its seating

on

the

rack housing.

To

this

dimension

must

be added

an

additional clearance

of

.0005

to

.003

in.

(.013

to

.076

mm.)

to

arrive

at

the

correct

thickness of shims which

must

be

placed beneath the

damper cover-plate.

Remove the

damper cover-plate and plunger and replace

the

assembly,

using

a

sealing

compound

to

make

an

oil-tight

joint.

Re■t

the rubber

gaiters

to

the housing and the

tie-rods.

Before

securing

the

gaiter

clip

on

the tie-rod

at

the

pinion

end, stand

the

assembly

upright, and

pour

in

i-pint

(.4

U.S.

MGB.

Issue5. 25729

Loading...

Loading...