M

THE BRAKING SYSTEM

Dismantling

the calliper

Further servicing

of the calliper

should be

con■ned

to

removing

the

bleeder

screw

and the

■uid

pipe

line

and

blowing

the

■uid

passages

clear with

compressed

air.

Unless

it

is

absolutely

unavoidable the calliper

should

not

be

separated

into

two

halves.

In

the

event

of

separation

becoming

essential, the ■uid

channel seal, clamping

bolts,

and lock

plates

must

be

renewed when

reassembling. Only

bolts

supplied by BMC Service

Ltd.

may

be

used.

0n

assembly these

must

be

tightened

with

a

torque

wrench

set

at

between 35.5

and 37

lb. ft. (4.9 and 5.1 kg.

m.).

Ensure

that

the calliper

faces

are

clean and that

the

threaded bolt holes

are

thoroughly dry. Make

certain

that

the

new

■uid channel

seal

is

correctly located

in

the

recessed face

before assembling

the

two

calliper halves.

Section M.7

BRAKE DISCS

Removing

Remove

the brake

calliper

as

detailed

in

Section M.6

without disconnecting

the

■uid supply and

withdraw the

hub by the

method described

in

Section

K.

Separate

the disc

from the hub

by

removing

the four

securing

nuts

and

washers.

Replacing

Assemble the brake

disc

to

the hub

and re■t the assembly

to

the swivel

hub.

Check

the disc

for

true

rotation

by clamping

a

dial

indicator

to

a

suitable fixed

point

on

the

vehicle with the

needle pad

bearing

on

the

face of the hub.

Run-out

must

not

exceed

.003

in.

(.076

mm.)

and

in

the

event

of this

A6076

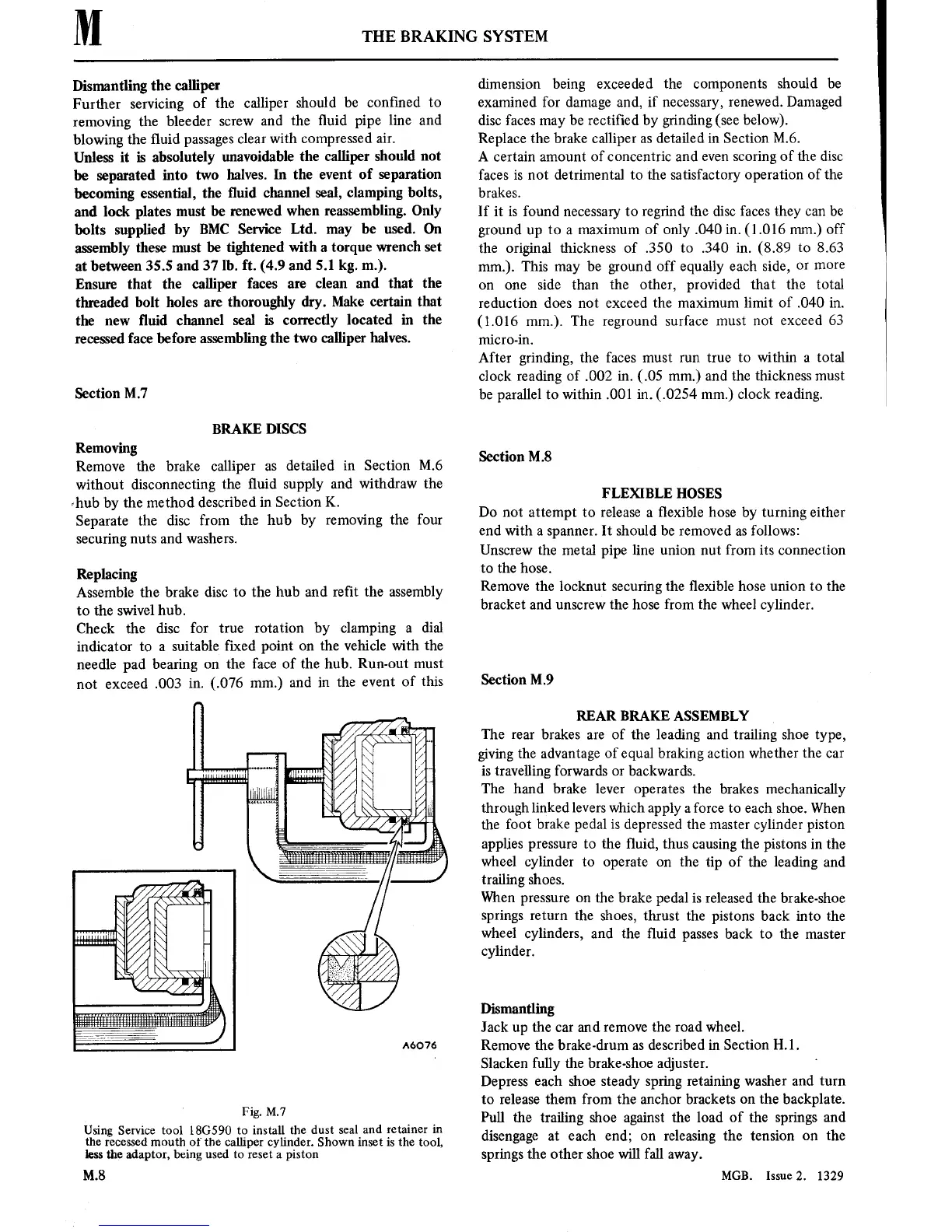

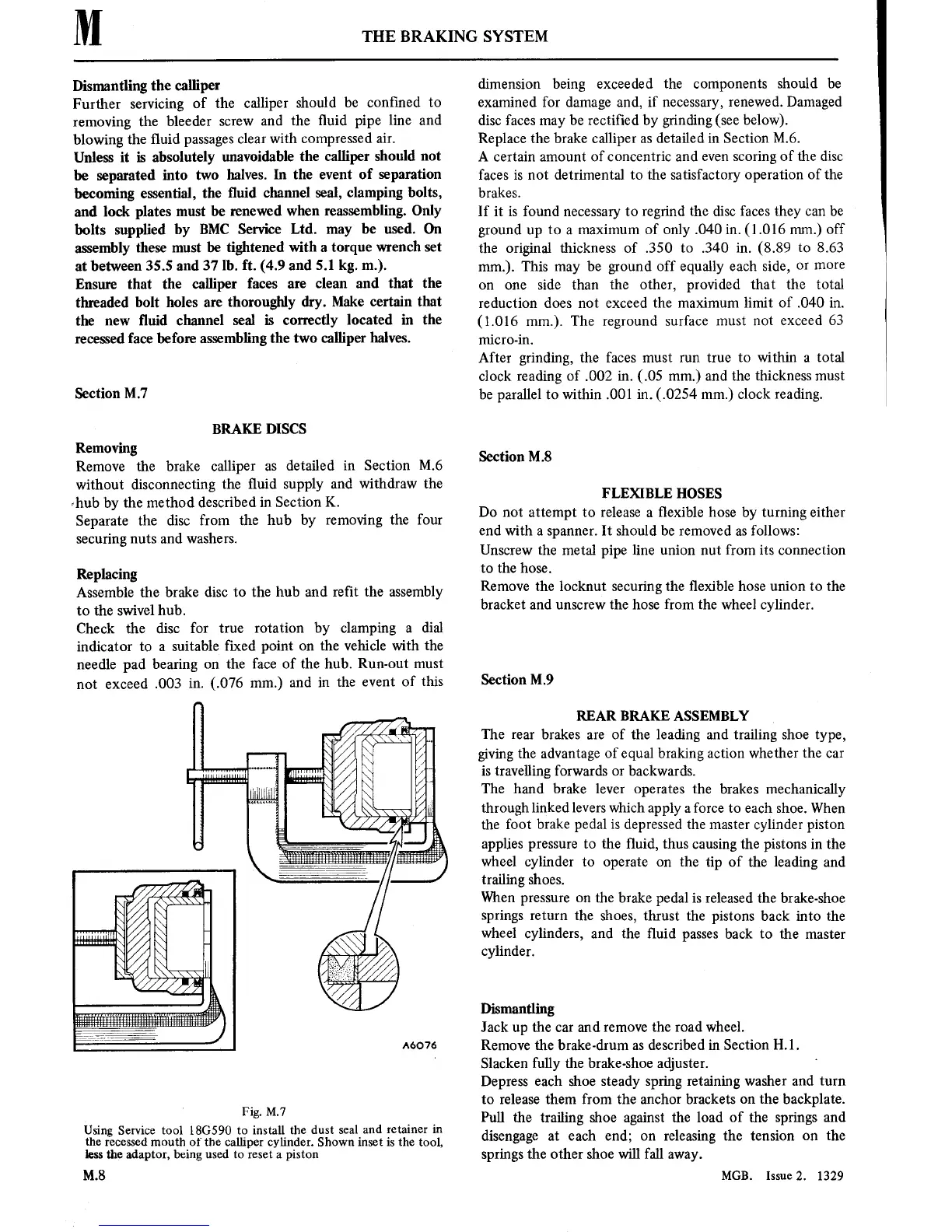

Fig.

M.7

Using

Service tool

18G590

to

install the

dust

seal

and retainer in

the recessedmouth

of

the calliper cylinder.

Shown inset is the

tool,

lessthe adaptor, being

used

to reset

a

piston

M.8

dimension being exceeded the

components

should be

examined

for

damage and,

if

necessary,

renewed. Damaged

disc faces

may

be

rectified by grinding

(see below).

Replace

the brake calliper

as

detailed

in

Section M.6.

A

certain

amount

of

concentric

and

even

scoring

of the

disc

faces

is

not

detrimental

to

the satisfactory

operation

of

the

brakes.

If

it is

found

necessary

to

regrind the disc faces they

can

be

ground

up

to

a

maximum

of

only .040

in.

(1.016 mm.) off

the original thickness

of

.350

to

.340

in.

(8.89

to

8.63

mm.).

This

may

be ground off equally each side,

or

more

on one

side than the other, provided

that the total

reduction

does

not

exceed the

maximum

limit

of

.040

in.

(1.016

mm.).

The

reground surface

must not

exceed

63

micro-in.

After grinding, the faces

must

run

true

to

within

a

total

clock reading of .002

in.

(.05 mm.)

and the thickness

must

be

parallel

to

within

.001

in.

(.0254 mm.)

clock reading.

Section M.8

FLEXIBLE HOSES

Do

not attempt to

release

a

■exible hose

by

turning

either

end with

a spanner.

It

should be removed

as

follows:

Unscrew the metal

pipe

line

union

nut

from

its connection

to

the

hose.

Remove the locknut

securing

the

■exible hose

union

to

the

bracket

and

unscrew

the

hose from the wheel

cylinder.

Section M.9

REAR BRAKE ASSEMBLY

The

rear

brakes

are

of

the leading and trailing shoe

type,

giving

the advantage

of

equal braking

action

whether the

car

is

travelling forwards

or

backwards.

The hand brake

lever

operates

the brakes mechanically

through

linked levers which

apply

a

force

to

each shoe.

When

the

foot

brake pedal

is

depressed the

master

cylinder

piston

applies

pressure

to

the ■uid, thus

causing

the

pistons in

the

wheel

cylinder

to operate

on

the

tip

of the

leading and

trailing

shoes.

When

pressure on

the brake

pedal

is

released the brake-shoe

springs

return

the shoes, thrust

the

pistons

back

into

the

wheel

cylinders, and the ■uid

passes

back

to

the

master

cylinder.

Dismantling

Jack

up

the

car

and

remove

the

road wheel.

Remove

the brake-drum

as

described

in

Section

H.l.

Slacken

fully the brake-shoe adjuster.

Depress

each shoe steady

spring retaining

washer and

turn

to

release

them from the anchor brackets

on

the

backplate.

Pull the

trailing

shoe

against

the load of the

springs

and

disengage

at

each

end;

on

releasing the

tension

on

the

springs

the other shoe

will

fall

away.

MGB.

Issue2. 1329

Loading...

Loading...