I

THE

GEARBOX (ALL SYNCHROMESH)

((((((((((O

\\\\\\\\

\\

\\\\\\\\

7

2.,\\\\\\\\\\

«((099

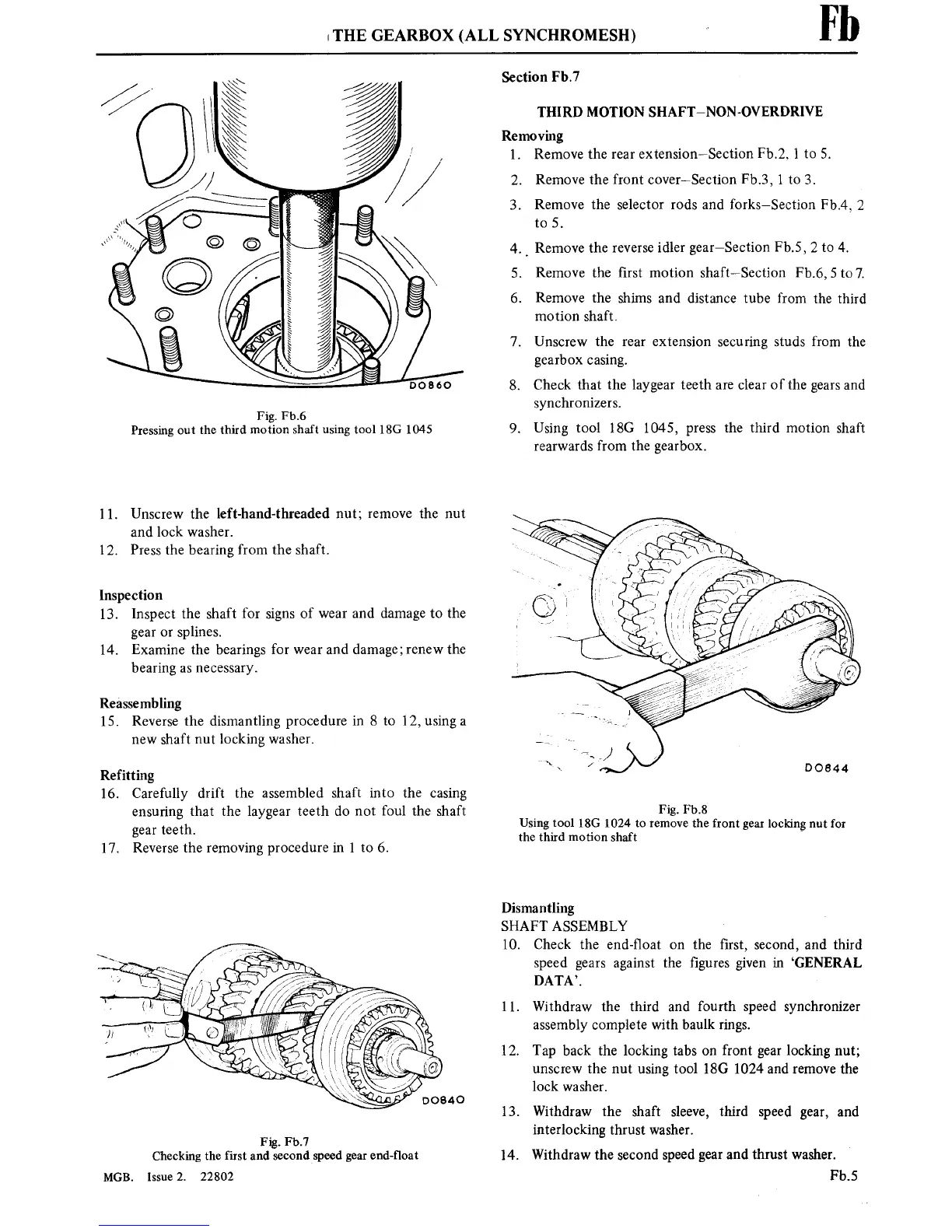

Fig. Fb.6

Pressing

out

the

third motion

shaft

using

tool 18G 1045

11.

Unscrew the

left-hand-threaded

nut;

remove

the

nut

and

lock washer.

12.

Press the

bearing

from the shaft.

Inspection

13.

Inspect

the

shaft for

signs

of

wear

and damage

to

the

gear or

splines.

14.

Examine

the

bearings

for

wear

and damage;

renew

the

bearing

as

necessary.

Reassembling

15. Reverse

the dismantling

procedure

in

8

to

12, using

a

new

shaft

nut

locking washer.

Refitting

16.

Carefully

drift the assembled shaft

into

the

casing

ensuring

that the laygear teeth do

not

foul the shaft

gear

teeth.

17.

Reverse

the

removing

procedure

in 1

to

6.

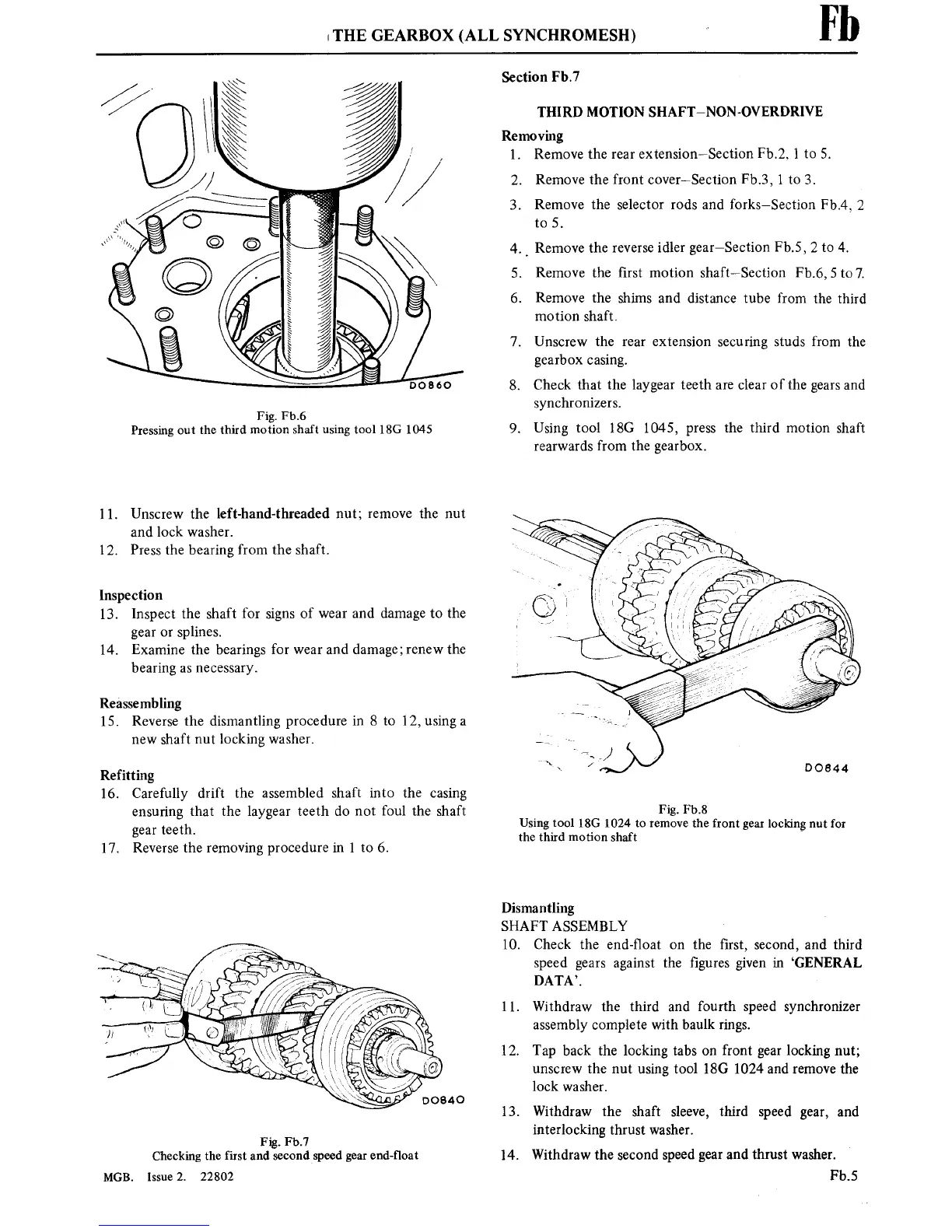

Fig. Fb.7

Checking the

first and

secondspeed

gear

end-float

MGB. Issue

2.

22802

Fl)

Section

Fb.7

THIRD

MOTION

SHAFT—NON-OVERDRIVE

Removing

1.

Remove

the

rear

extensionWSection

Fb.2,

l

to

5.

2.

Remove

the

front

coveriSection

Fb.3,

1

to

3.

3.

Remove

the selector

rods and

forks—Section

Fb.4,

2

to

5.

4.

_

Remove

the

reverse

idler gear—Section

Fb.5,

2

to

4.

Remove

the ■rst

motion

shaftiSection

F b.6,

5

to

7.

6.

Remove the shims

and distance

tube

from

the

third

motion

shaft.

7.

Unscrew the

rear

extension

securing

studs

from

the

gearbox

casing.

8.

Check that the laygear

teeth

are

clear

of the

gears

and

synchronizers.

9.

Using tool

ISO

1045,

press

the

third

motion

shaft

rearwards

from the

gearbox.

Fig. Fb.8

Using tool 18G

1024

to

remove

the front

gear

locking

nut

for

the third motion shaft

Dismantling

SHAFT

ASSEMBLY

10.

Check the end-■oat

on

the ■rst, second, and third

speed

gears

against

the ■gures

given in

‘GENERAL

DATA’.

11.

Withdraw

the

third and

fourth speed synchronizer

assembly complete

with

baulk

rings.

12.

Tap back the

locking

tabs

on

front

gear

locking

nut;

unscrew

the

nut

using

tool 180

1024 and

remove

the

lock washer.

13.

Withdraw the shaft sleeve, third speed

gear,

and

interlocking thrust washer.

14.

Withdraw the second speed

gear

and thrust washer.

Fb.5

Loading...

Loading...