THE ENGINE

A

rotates

the cylinder until the

next

recess

in

the lower

edge

of

the slot

comes

into

line with the

limiting

peg

and

prevents

the plunger

returning

to

its original

position and

allowing

the

timing

chain

to

become

slack

again.

When reassembling,

insert

the

spring

in

the plunger

and

place the cylinder

on

the other

end

of the

spring.

Compress

the

spring

until the cylinder

enters

the

plunger

bore,

engaging

the helical slot with

the

peg

in

the plunger.

Hold the assembly compressed

in

this

position

and

engage

the Allen key.

Turn

the

cylinder clockwise until the

end

of

the cylinder

is

below the

peg

and the

spring is

held

compressed. Withdraw the key and

insert

the plunger

assembly

in

the body. Replace the backplate

and

secure

the

assembly

to

the

cylinder

block.

After re■tting the

tensioner,

check the slipper head

for

freedom

of

movement

and

ensure

that

it

does

not

bind

on

the backplate

when

it is

moved

in

the

body.

When the

timing

chain

is

in position

the

tensioner is

released for

operation

by

inserting

the key

and

turning it

clockwise

until the slipper

head

moves

forward under

spring

pressure

against

the chain.

Do

not attempt to turn

the key anti-clockwise

or

force the

slipper

head

into

the chain

by

external

pressure.

Secure

the bolts with the locking

plate, replace

the bottom

plug, and lock with

a

tab washer.

Section

A.“

SUMP AND STRAINER

Drain the radiator and disconnect

the

hoses, drain the

sump,

and then release the

engine

front

mounting

bolts.

Sling

the

engine

and

lift

it

suf■ciently

to

gain

access

to

the

front

sump

bolts.

Remove

all the bolts

and withdraw

the

sump

from the

crankcase.

To

remove

the oil

strainer

remove

the

two

bolts

securing

it

to

the

pump

cover.

The

strainer

may

be dismantled

for cleaning by

removing

the

centre-nut

and

bolt

and the

two

delivery

pipe

■ange

bolts. Note

that there

is

a

locating

tongue

on

the

side of the

cover

which

must

be positioned

correctly when replacing.

Remember also

to

replace the

distance tube.

Clean

out

the

sump

and

strainer

with

paraf■n (kerosene)

and

a

stiff brush;

never use rag.

When

re■tting the

sump

to

the

engine give

particular

attention

to

the sealing gaskets

for

the crankcase

face

and

the

two

oil

seal

packings

for

the crankcase

which ■t

into

recesses

in

the crankcase.

If the gaskets

are

in

good condition

and have

not

been

damaged

during removal

of the

sump

they

may

be used

again,

but

it is

always

advisable

to

■t

new ones.

Before

■tting

new

gaskets

remove

all

traces

of the

old

ones

from

the

sump

and crankcase

faces.

Smear the faces of

the

crankcase joint

with

grease

and

■t

the

two

halves of the

large gasket. Lift the

sump

into position

on

the crankcase,

insert

the

19

bolts, and

tighten them evenly.

MGB. Issue

3. 1329

Re■t

the

engine

to

its

mountings

and the hoses

to

the

radiator. Re■ll the radiator and the

sump

with coolant

and

fresh

oil

respectively.

Section

A.12

OIL PUMP

Two

bolts

secure

the oil

pump cover

and three studs

secure

the

pump

to

the

crankcase.

Unscrew

the

stud

nuts

and

remove

the

pump

and drive shaft.

When re■tting the

pump use

a new

joint

washer.

Unscrew

the

two

securing

screws

and carefully

withdraw

the

cover,

which

is

located

on

the

base of the

oil

pump

body

by

two

dowels.

Withdraw the

outer

rotor,

and

the

inner

rotor

complete

with

oil

pump

shaft, from

the

pump

body.

Thoroughly

clean

all

parts

in

paraf■n (kerosene)

and

inspect

them

for

wear.

The

rotor

end-■oat

and

lobe

clearances

should

be checked

as

follows:

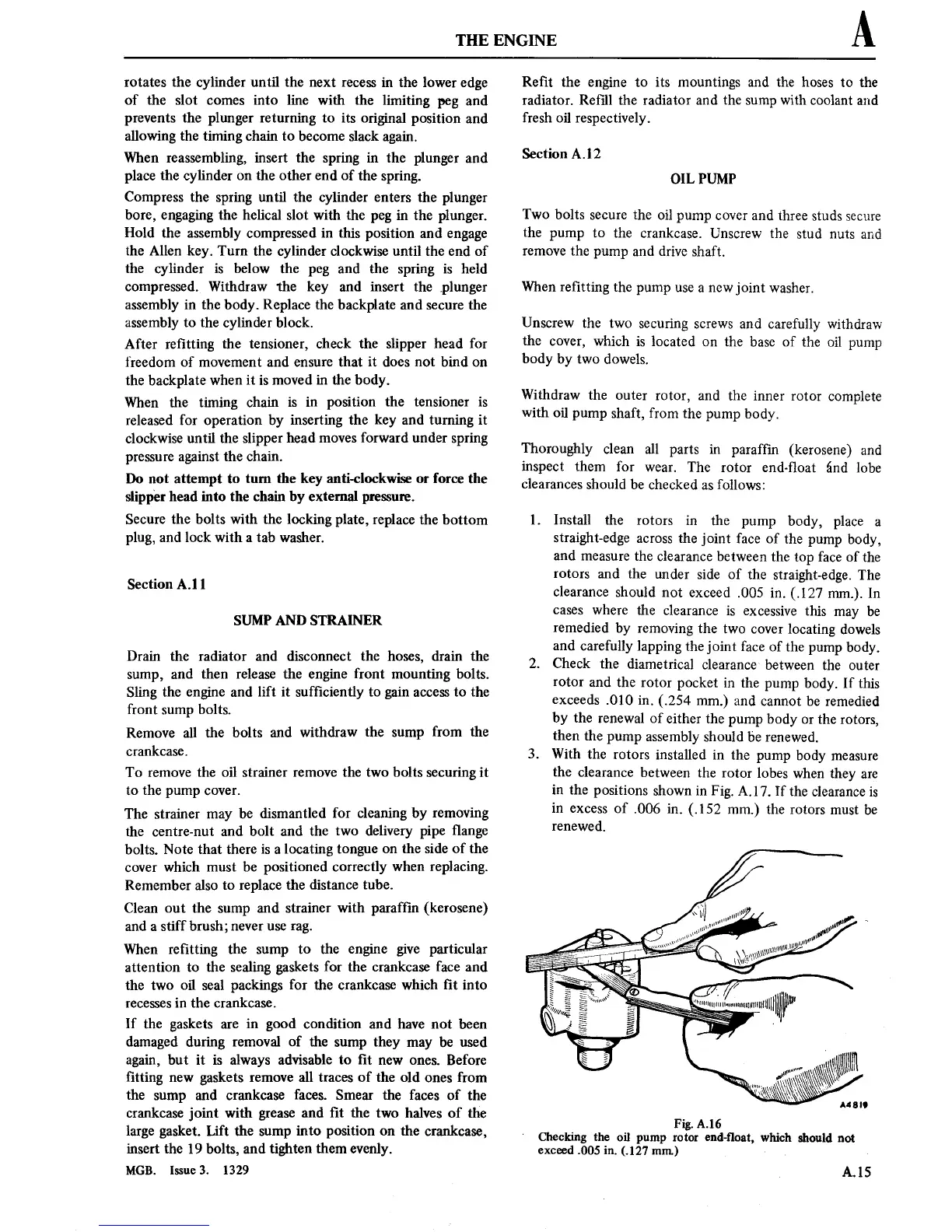

1. Install the

rotors

in

the

pump

body, place

a

straight-edge

across

the

joint face of

the

pump

body,

and

measure

the

clearance

between the

top

face of

the

rotors

and the

under side of the

straight-edge.

The

clearance

should

not

exceed

.005

in.

(.127

mm.).

In

cases

where the

clearance

is excessive

this

may

be

remedied by

removing

the

two

cover

locating

dowels

and carefully

lapping

the

joint

face

of the

pump

body.

2.

Check

the diametrical

clearance

between the

outer

rotor

and the

rotor

pocket

in

the

pump

body. If this

exceeds

.010

in.

(.254

mm.)

and

cannot

be remedied

by

the

renewal

of either the

pump

body

or

the

rotors,

then the

pump

assembly should

be

renewed.

3.

With

the

rotors

installed

in

the

pump

body

measure

the

clearance

between the

rotor

lobes

when they

are

in

the

positions

shown

in

Fig.

A.17.

If

the

clearance

is

in

excess

of

.006

in.

(.152

mm.) the

rotors

must

be

renewed.

Fig. A.16

Checking

the oil

pump

rotor

end-■oat,

which should

not

exceed

.005 in.

(.127 mm.)

A.15

Loading...

Loading...