THE

IGNITION

SYSTEM

B

SDIO76W

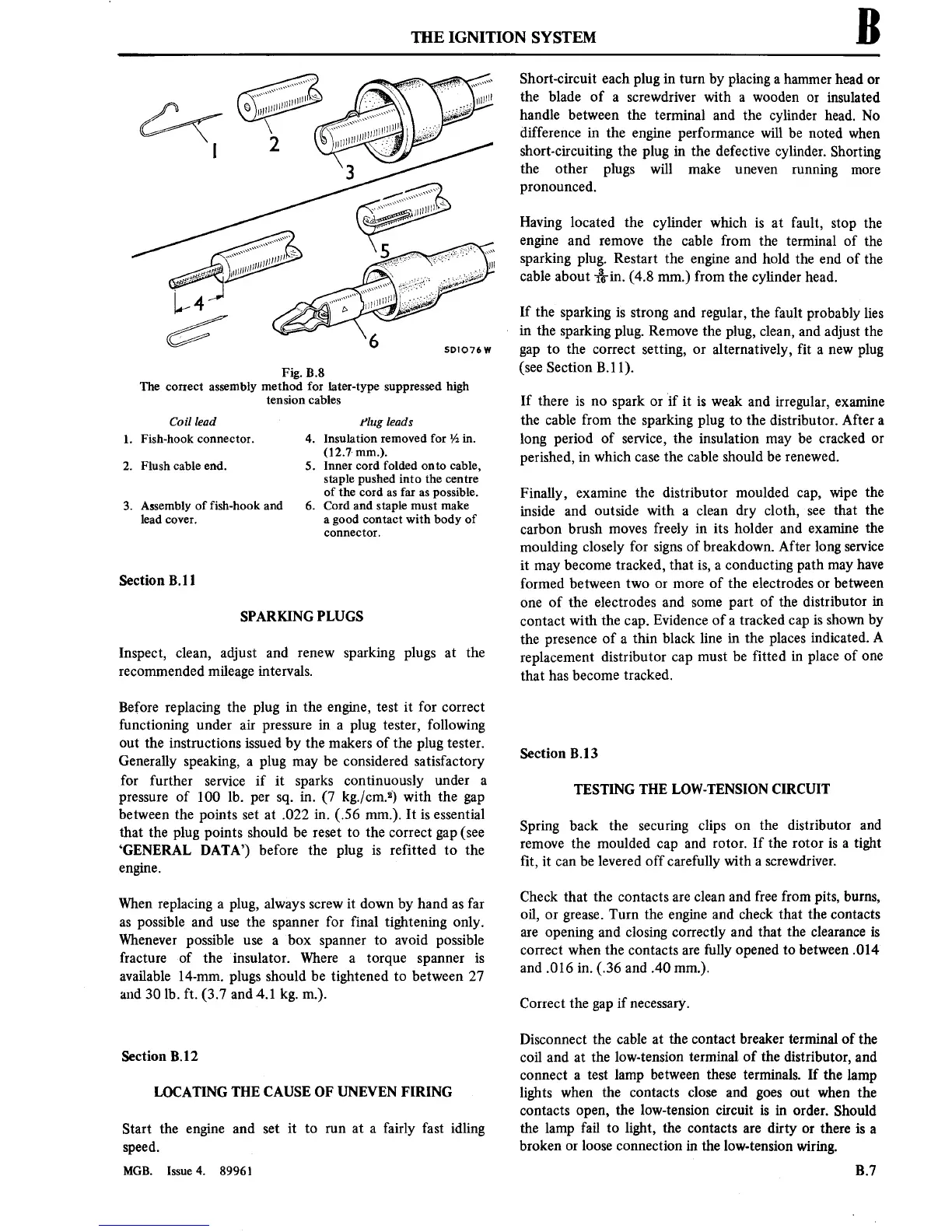

Fig. B.8

The

correct

assembly

method for

later-type

suppressedhigh

tension cables

Coil lead

I’Iug leads

1.

Fish-hook

connector.

4. Insulation removed

for 1/2

in.

(12.7-

mm.).

2.

Flush cableend. 5. Inner

cord folded

onto

cable,

staple pushed into the

centre

of the

cord

as

far

as

possible.

3.

Assembly

of fish-hook and 6. Cord and staple

must

make

lead

cover. a

good

contact

with body of

connector.

Section

8.11

SPARKING PLUGS

Inspect,

clean, adjust

and

renew

sparking plugs

at

the

recommended mileage intervals.

Before replacing

the

plug

in

the

engine,

test

it

for

correct

functioning

under

air

pressure

in

a

plug

tester,

following

out

the

instructions

issued

by the

makers

of

the

plug

tester.

Generally

speaking,

a

plug

may

be

considered satisfactory

for further

service

if

it

sparks

continuously under

a

pressure

of

100

lb.

per

sq.

in.

(7

kg./cm.2’)

with

the

gap

between the

points

set at

.022 in.

(.56 mm).

It is

essential

that the plug

points

should be

reset to

the

correct

gap

(see

‘GENERAL

DATA’) before

the plug

is

refitted

to

the

engine.

When replacing

a

plug, always

screw

it

down by

hand

as

far

as

possible and

use

the

spanner

for final

tightening only.

Whenever

possible

use a

box

spanner

to

avoid possible

fracture

of the

insulator.

Where

a

torque

spanner

is

available

14-min.

plugs

should be tightened

to

between

27

and 301b. ft. (3.7 and

4.1

kg.

m.).

Section B.l2

LOCATIN'G THE

CAUSE OF UNEVEN

FIRING

Start

the

engine

and

set

it

to

run

at

a

fairly fast

idling

speed.

MGB.

Issue

4.

89961

Short-circuit each plug

in

turn

by

placing

a

hammer

head

or

the blade of

a

screwdriver with

a

wooden

or

insulated

handle

between the terminal and the cylinder

head.

No

difference

in

the

engine

performance

will be

noted when

short-circuiting

the plug

in

the defective

cylinder. Shorting

the other

plugs will make

uneven

running

more

pronounced.

Having located the

cylinder which

is

at

fault,

stop

the

engine

and

remove

the cable

from

the terminal of the

sparking plug. Restart the

engine

and hold the

end

of

the

cable about

jag-in.

(4.8 mm.) from

the

cylinder head.

If

the

sparking

is

strong

and regular, the fault

probably lies

-

in

the

sparking plug.

Remove

the

plug, clean, and adjust the

gap

to

the

correct

setting,

or

alternatively, fit

a

new

plug

(see

Section

B.l

1).

If

there

is

no

spark

or

if

it is

weak and

irregular,

examine

the cable

from

the sparking

plug

to

the distributor.

After

a

long

period

of

service,

the

insulation

may

be cracked

or

perished,

in

which

case

the cable

should be renewed.

Finally,

examine

the

distributor moulded

cap,

wipe

the

inside

and outside

with

a

clean

dry cloth,

see

that

the

carbon

brush

moves

freely

in its

holder and

examine

the

moulding

closely for

signs

of breakdown. After long service

it

may

become tracked,

that

is,

a

conducting

path

may

have

formed between

two

or more

of the electrodes

or

between

one

of the electrodes and

some

part

of the distributor

in

contact

with the

cap.

Evidence of

a

tracked

cap

is

shown

by

the

presence

of

a

thin

black line

in

the places

indicated. A

replacement

distributor

cap

must

be

fitted

in

place

of

one

that

has become

tracked.

Section B. l 3

TESTING THE LOW-TENSION

CIRCUIT

Spring

back the

securing

clips

on

the

distributor and

remove

the moulded

cap

and

rotor.

If

the

rotor

is

a

tight

■t,

it

can

be levered

off carefully with

a

screwdriver.

Check that the

contacts

are

clean

and free from

pits,

burns,

oil,

or grease.

Turn

the

engine

and

check that the

contacts

are

opening

and closing

correctly and that the clearance

is

correct

when the

contacts

are

fully opened

to

between

.014

and

.016

in.

(.36

and .40

mm).

Correct the

gap

if

necessary.

Disconnect

the cable

at

the

contact

breaker terminal of the

coil and

at

the low-tension

terminal

of the

distributor,

and

connect

a

test

lamp

between these terminals. If the

lamp

lights

when the

contacts

close and

goes

out

when

the

contacts

open,

the low-tension

circuit is in

order. Should

the lamp

fail

to

light, the

contacts

are

dirty

or

there

is

a

broken

or

loose

connection

in

the

low-tension

wiring.

B.7

Loading...

Loading...